Sliding pin type shelf board bracket of cabinet

A laminate bracket and sliding pin technology, applied in the field of furniture spare parts, can solve the problems of inconvenient loading and unloading, complicated loading and unloading operation process, complicated process, etc., and achieve the effect of simple and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

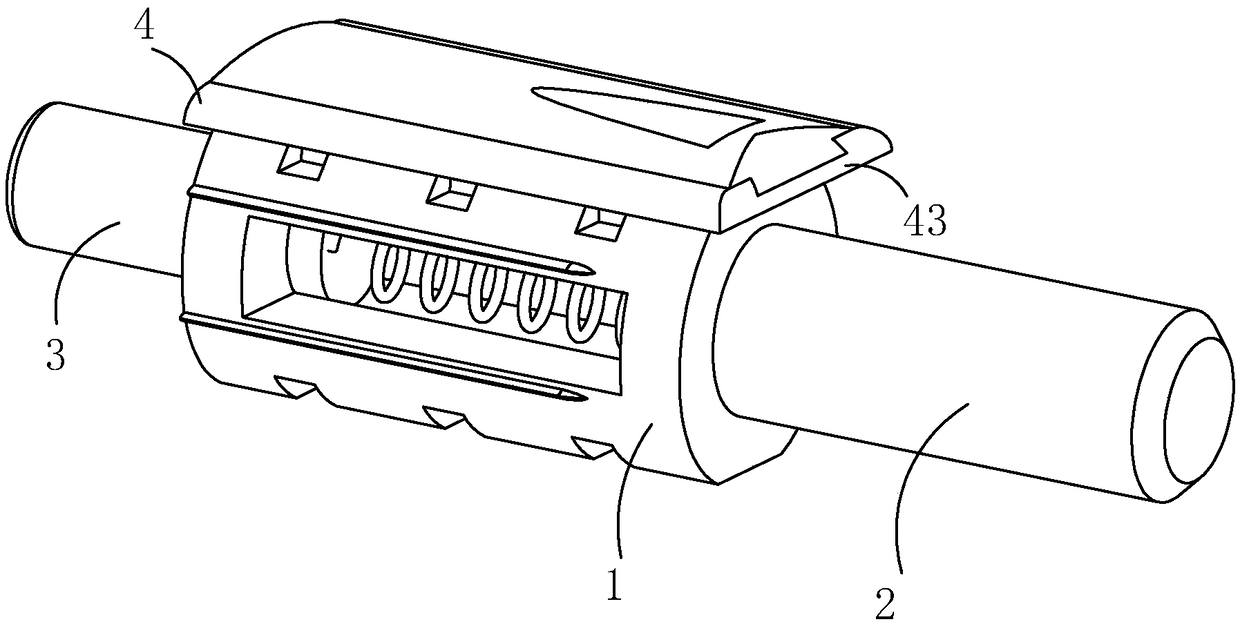

[0032] like figure 1 As shown, a cabinet sliding pin type shelf support includes a mounting block 1, a fixing pin 2 and a sliding pin 3, the fixing pin 2 is fixedly arranged on one end surface of the mounting block 1, the mounting block 1 is made of polyamide, and the polyamide Amide has good comprehensive properties such as mechanical properties, heat resistance, wear resistance, chemical resistance and self-lubricating property, and has low friction coefficient, certain flame retardancy, and is easy to process.

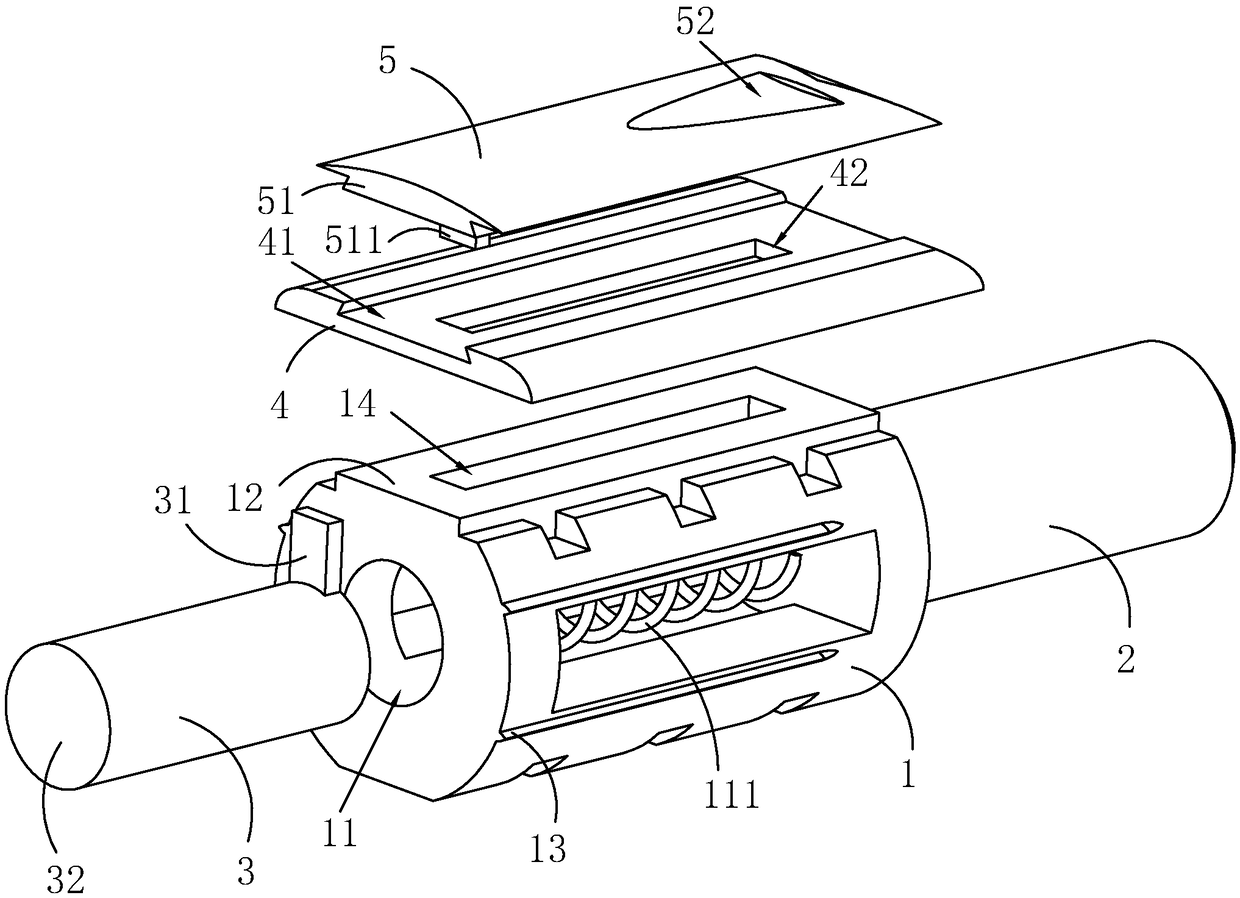

[0033] like figure 2 As shown, the end face of the mounting block 1 away from the fixing pin 2 is provided with a mounting hole 11 in the direction of the fixing pin 2. The depth of the mounting hole 11 is smaller than the length of the mounting block 1. The sliding pin 3 is slidably arranged in the mounting hole 11. The sliding pin 3 adopts Made of zinc alloy, the sliding pin 3 and the fixing pin 2 are both cylindrical, the diameter of the sliding pin 3 is smalle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com