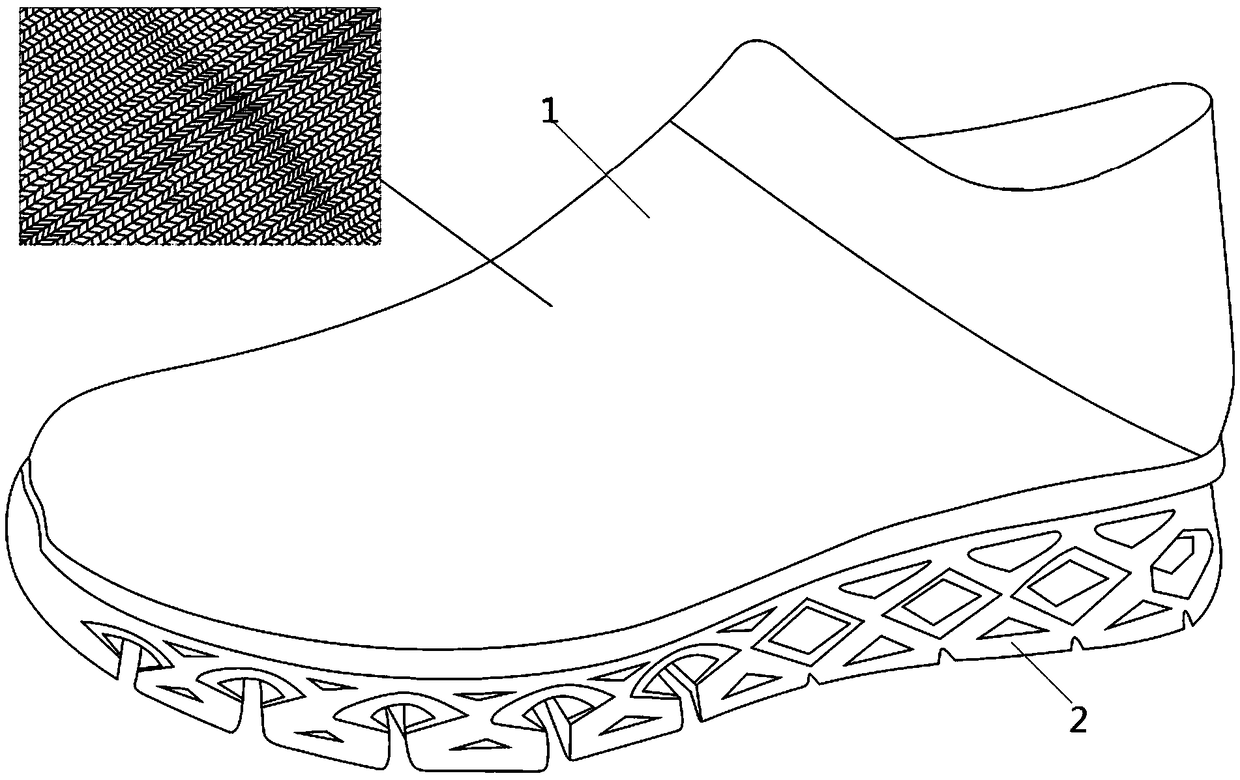

Fungus killing fiber antibacterial shoe and manufacturing method thereof

A manufacturing method, antibacterial shoe technology, applied in the field of shoe manufacturing, to achieve the effects of eliminating process quality inspection, high manufacturing efficiency, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the modified acrylic fiber is as follows: immerse the acrylic fiber in the chemical bath for 20-30s at room temperature, adjust the pH of the chemical bath to 3.0-4, put it into boiling water and wash it for 20-30s, and then dry it at 70-90°C Dry for 30-40s.

[0036] The formula of modified polyester is: it is made of modified resin, and the production raw materials of modified resin include high-fiber polyester, asbestos fiber, oxidizing agent and vulcanizing machine; high-fiber polyester accounts for 80-90% of the raw material, and asbestos fiber accounts for the raw material 2-4% of the raw material, the oxidizing agent accounts for 5-10% of the raw material percentage, and the vulcanizing machine accounts for 3-6% of the raw material percentage.

[0037] The preparation method of the modified cotton fiber is as follows: the cotton fiber is placed in an airtight container, filled with a modified medium, the pressure is increased to the modif...

Embodiment 1

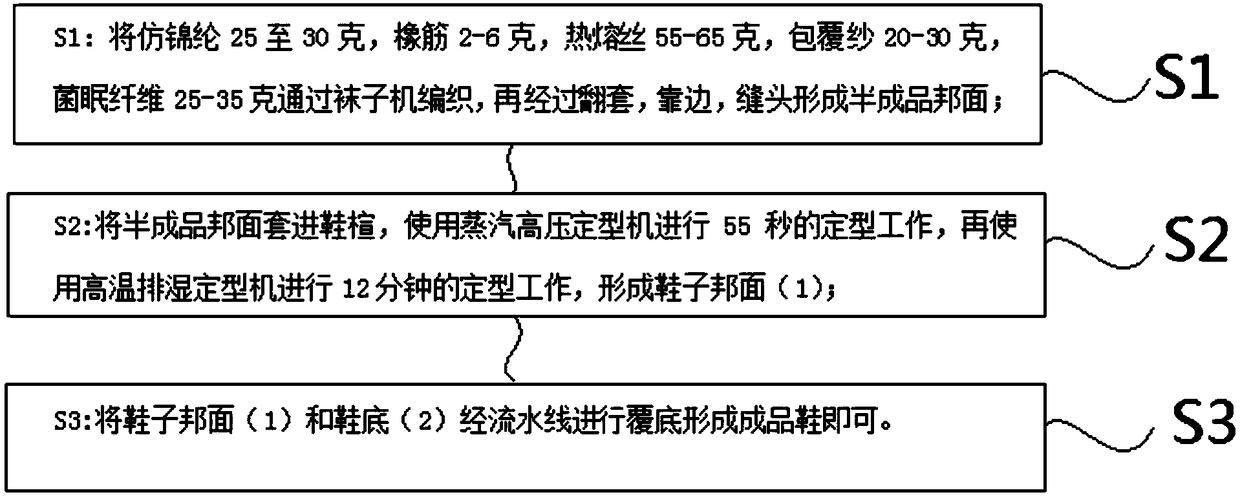

[0042] Such as Figure 2 to Figure 3 Shown, a kind of manufacture method of hypnosis fiber antibacterial shoes is characterized in that, comprises the following steps

[0043] S1: Weave 25 grams of imitation nylon, 2 grams of elastic, 55 grams of thermal fuse, 20 grams of covering yarn, and 25 grams of mycetaminophen fiber through a sock machine, and then turn it over, pull it aside, and sew it to form a semi-finished fabric;

[0044] S2: put the semi-finished noodles into the shoe last, use a steam high-pressure shaping machine for 55 seconds of shaping work, and then use a high-temperature dehumidification shaping machine for 12 minutes of shaping work to form shoe noodles 1;

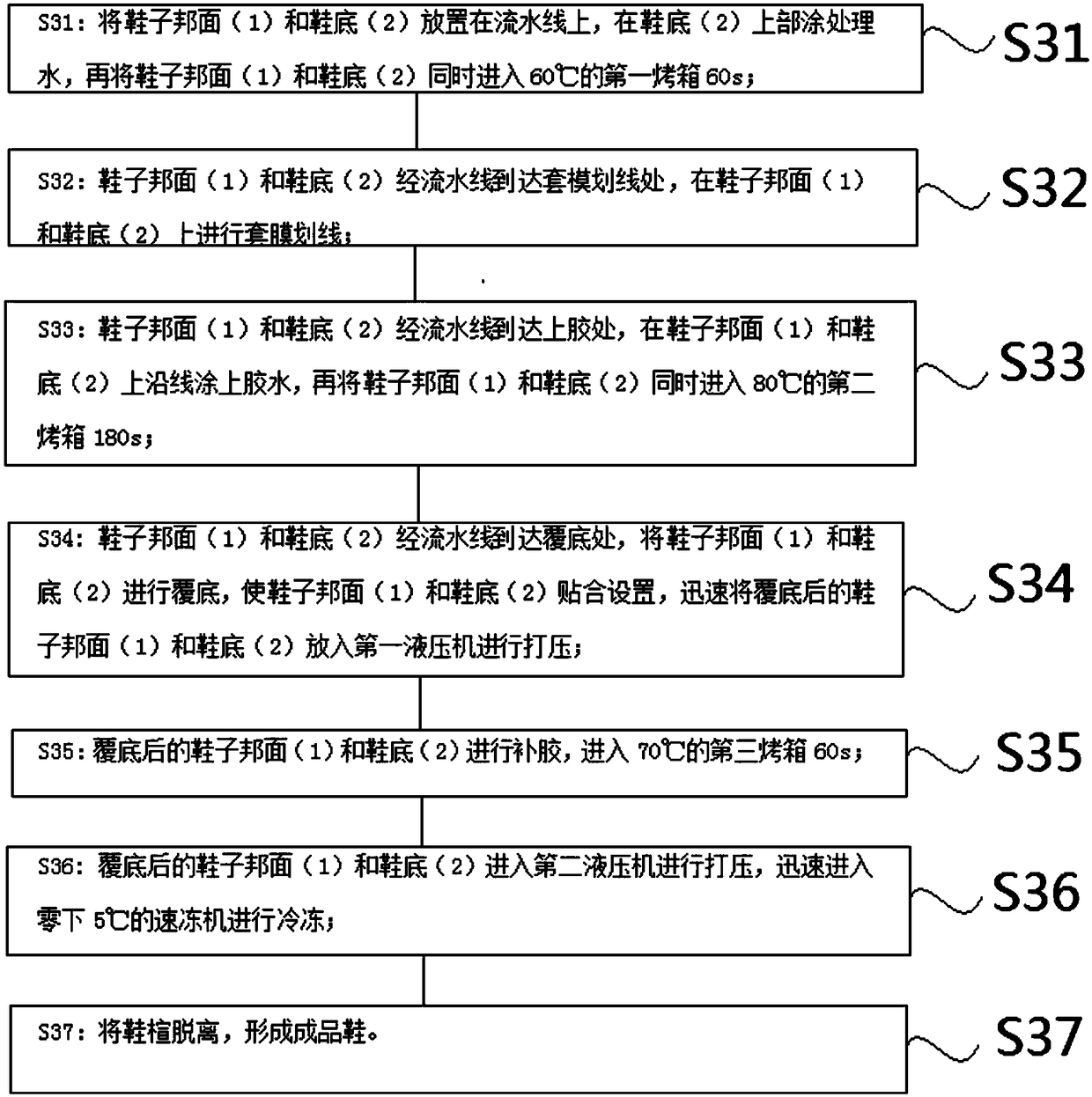

[0045] S3: Cover the shoe surface 1 and the sole 2 through the assembly line to form a finished shoe.

[0046]Further, in step S2, the temperature of the steam high-pressure setting machine is 170 degrees Celsius.

[0047] Further, in step S2, the temperature of the high-temperature dehumidification...

Embodiment 2

[0059] S1: Weave 30 grams of imitation nylon, 4 grams of elastic, 60 grams of thermal fuse, 40 grams of covered yarn, and 30 grams of hypnotin fiber through a sock machine, and then turn it over, pull it aside, and sew it to form a semi-finished fabric. The remaining steps are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com