Preparation method of in-bag fermented pickled baby Chinese cabbages

A baby cabbage and kimchi technology, applied in biotechnology and food fields, can solve the problems of uncontrollable fermentation, large discharge of high-salt and high-acid wastewater, unstable color and flavor, etc., and achieve the effect of prolonging the fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

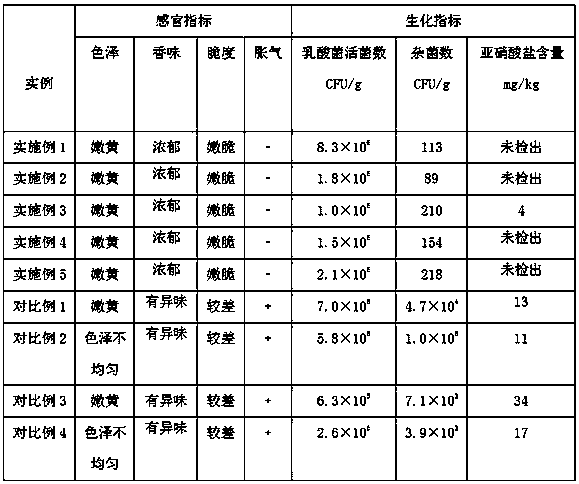

Examples

Embodiment 1

[0099] The preparation of fermented baby cabbage kimchi in embodiment 1 50kg bag

[0100] A. Pretreatment

[0101] Weigh 100kg of fresh baby vegetables after removing impurities and inedible parts, then process baby vegetables into required shapes and sizes, wash and set aside;

[0102] B. Disinfect and clean

[0103] The baby cabbage pretreated by step A is disinfected with an aqueous solution of trichloroisocyanuric acid with a mass concentration of 0.01‰ for 5 minutes to control the number of microorganisms in the baby cabbage to ≤300CFU / g; then rinse with water for 3 minutes, drain and set aside;

[0104] C. Pickled and dehydrated

[0105] Put the baby dish washed in step B into a mixer, add 5Kg of iodine-free salt according to 5% of the weight of the baby dish, pickle it for 5 hours after stirring, then carry out centrifugal dehydration treatment, and obtain 50kg of dehydrated baby dish after pickling and dehydration Vegetables, the total yield is 50%;

[0106] D. Raw...

Embodiment 2

[0126] The preparation of fermented baby cabbage kimchi in embodiment 2 200kg bag

[0127] A. Pretreatment

[0128] Weigh 250kg of fresh baby vegetables after removing impurities and inedible parts, then process baby vegetables into required shapes and sizes, wash and set aside;

[0129] B. Disinfect and clean

[0130] The baby cabbage pretreated by step A is disinfected with an aqueous dichloroisocyanuric acid solution with a mass concentration of 1.00‰ for 3 minutes to control the number of microorganisms in the baby cabbage to ≤300CFU / g; rinse with water for 4 minutes, drain and set aside;

[0131] C. Pickled and dehydrated

[0132] Put the baby vegetables rinsed in step B into the mixer, add 5Kg of iodine-free salt according to 2% of the weight of the baby vegetables, pickle after stirring for 24 hours, then press and dehydrate, and obtain 200kg of dehydrated baby vegetables after pickling and dehydration Vegetables, the total yield is 80%;

[0133] D. Raw material mix...

Embodiment 3

[0153] The preparation of fermented baby cabbage kimchi in embodiment 3 1000kg bag

[0154] A. Pretreatment

[0155] Weigh 1667kg after fresh baby vegetables are sorted out to remove impurities and inedible parts, then baby vegetables are processed into required shapes and sizes, cleaned, and set aside;

[0156] B. Disinfect and clean

[0157] The baby cabbage pretreated by step A is disinfected with an aqueous solution of chlorine dioxide with a mass concentration of 0.20‰ for 4 minutes, and the number of microorganisms in the baby cabbage is controlled to be ≤300CFU / g; rinse with clean water for 5 minutes, and drain for later use;

[0158] C. Pickled and dehydrated

[0159] Put the baby vegetables rinsed in step B into the mixer, add 80Kg of iodine-free salt according to the weight of the baby vegetables, pickle them for 15 hours after stirring, and then carry out centrifugal dehydration treatment to obtain 1000kg of dehydrated baby vegetables after pickling and dehydratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com