Low-temperature and low-salt tank type fermenting preparation method of broad bean sauce halves

A technology of broad bean paste and broad beans, applied to bacteria used in food preparation, food ingredients containing yeast, food ingredients as odor improvers, etc., can solve problems such as unstable product quality, large food safety risks, and susceptibility to environmental pollution , to achieve the effect of realizing industrialization and automation, facilitating industrialization, and good controllability of fermentation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

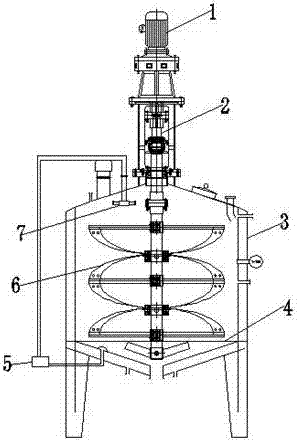

Image

Examples

Embodiment 1

[0043] The present embodiment takes 86.57kg broad bean split raw material to prepare broad bean sauce flap as an example to describe in detail.

[0044] A low-temperature and low-salt tank type fermentation preparation method of broad bean paste, comprising the steps of:

[0045] A. Pre-treatment of broad bean flaps: Weigh 86.57kg of dried broad bean flaps, select 84.84kg of broad bean flaps after being selected by a bean sorting machine and cleaned by a washing machine, put them into a cooking pot, add clear water to the cooking pot until the water level of the broad bean flaps is submerged, and place Heat the steam to above 95°C and keep cooking for 2.5 minutes; drain the cooked broad bean flaps into the cold auger and cool to 40°C, and spread the broad bean flaps to increase the weight to 160.44kg and absorb 75.60kg of water, and set aside;

[0046] B. Making broad bean koji material: a Mixing material: 10.5kg flour and 0.252kg Aspergillus oryzae are respectively connected ...

Embodiment 2

[0051] This embodiment is illustrated by taking 141.0kg broad bean splits to prepare broad bean sauce splits as an example.

[0052] A low-temperature and low-salt tank type fermentation preparation method of broad bean paste, comprising the steps of:

[0053]A. Pre-treatment of broad bean flaps: Weigh 141.0 kg of dried broad bean flaps, select by a bean sorting machine, and wash with a washing machine to obtain 138.2 kg of broad bean flaps. Heat the steam to above 95°C and keep cooking for 2 minutes; drain the cooked broad bean flap into the cold auger to cool to 40°C, and spread the broad bean flap to increase the weight to 261.36kg, absorb water 123.15kg, and set aside;

[0054] B. Making broad bean koji material: a Mixing material: 17.1kg flour and 0.41kg Aspergillus oryzae are respectively connected to the mixing equipment through the inoculation powder receiver equipment, and fully mixed with the boiled and cooled broad bean watercress evenly, Stirring time is 15 minute...

Embodiment 3

[0059] This embodiment is illustrated by taking 705.0kg broad bean splits to prepare broad bean sauce splits as an example.

[0060] A low-temperature and low-salt tank type fermentation preparation method of broad bean paste, comprising the steps of:

[0061] A. Pre-treatment of broad bean flaps: Weigh 705.0 kg of dried broad bean flaps, select 691.0 kg of broad bean flaps after being selected by a bean sorting machine and cleaned by a washing machine, put them into a cooking pot, add clear water to the cooking pot until the water level of the broad bean flaps is submerged, and place Heat the steam to above 95°C and keep cooking for 1.5 minutes; drain the cooked broad bean flaps into the cold auger and cool to 40°C, and spread the broad bean flaps to increase the weight to 1306.8kg, absorb water 615.75kg, and set aside;

[0062] B. Making broad bean koji material: a Mixing material: Connect 85.5kg flour and 2.05kg of Aspergillus oryzae to the mixing equipment through the inoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com