Organic electroluminescent device and organic electroluminescent device

An electroluminescent device and electroluminescent technology, which are applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of low luminous brightness and color shift of red sub-pixels and green sub-pixels, so as to improve luminous efficiency and reduce emission. Bright voltage, the effect of reducing the electron injection barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

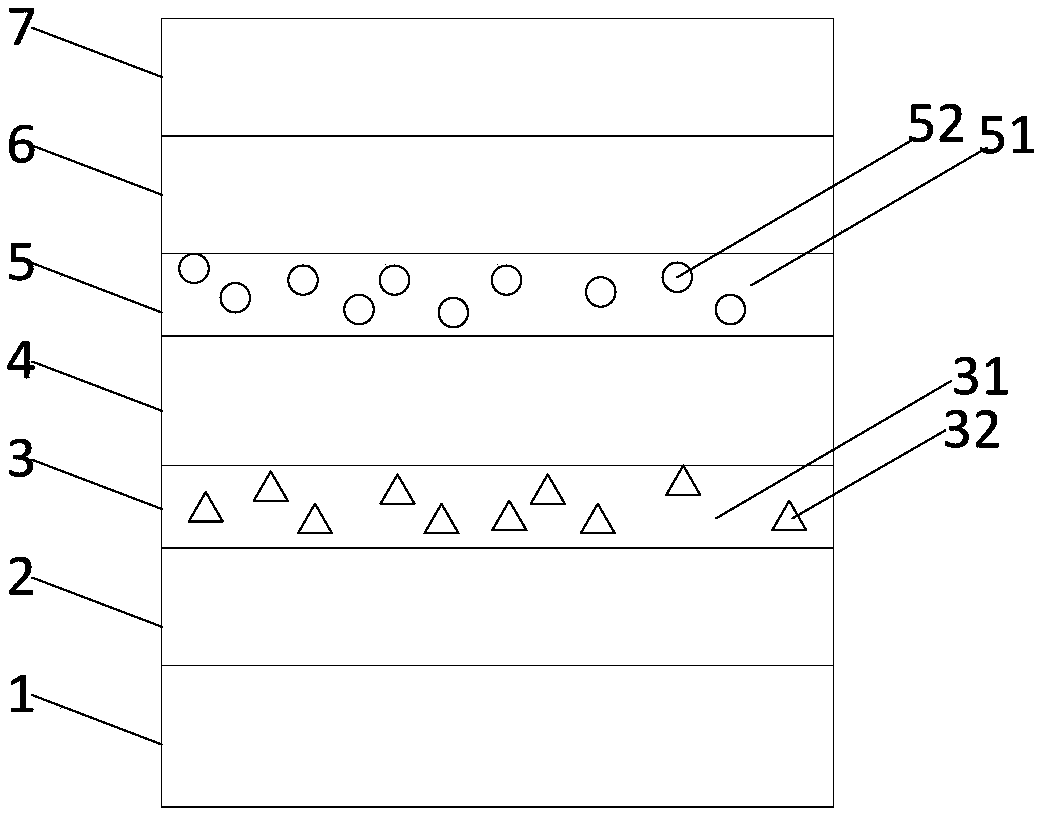

[0038] An embodiment of the present invention provides an organic electroluminescent device, such as figure 1 As shown, it includes a first electrode layer 1 , a first carrier functional layer 2 , a light emitting layer 4 and a second electrode layer 7 which are stacked. The first electrode layer 1 is an anode, and the second electrode layer 7 is a cathode, or the first electrode layer 1 is a cathode, and the second electrode layer 7 is an anode. Hereinafter, the first electrode layer 1 is used as an anode, and the second electrode layer 7 is used as a cathode as an example for illustration.

[0039] In the prior art, the process of lighting an organic electroluminescent device is to apply a certain driving voltage to the first electrode layer 1 and the second electrode layer 7, so that the carriers are transported across the potential barrier to the light-emitting layer 4, and finally emit light Layer 4 composite emits light. It can be known that the size of the potential b...

Embodiment 2

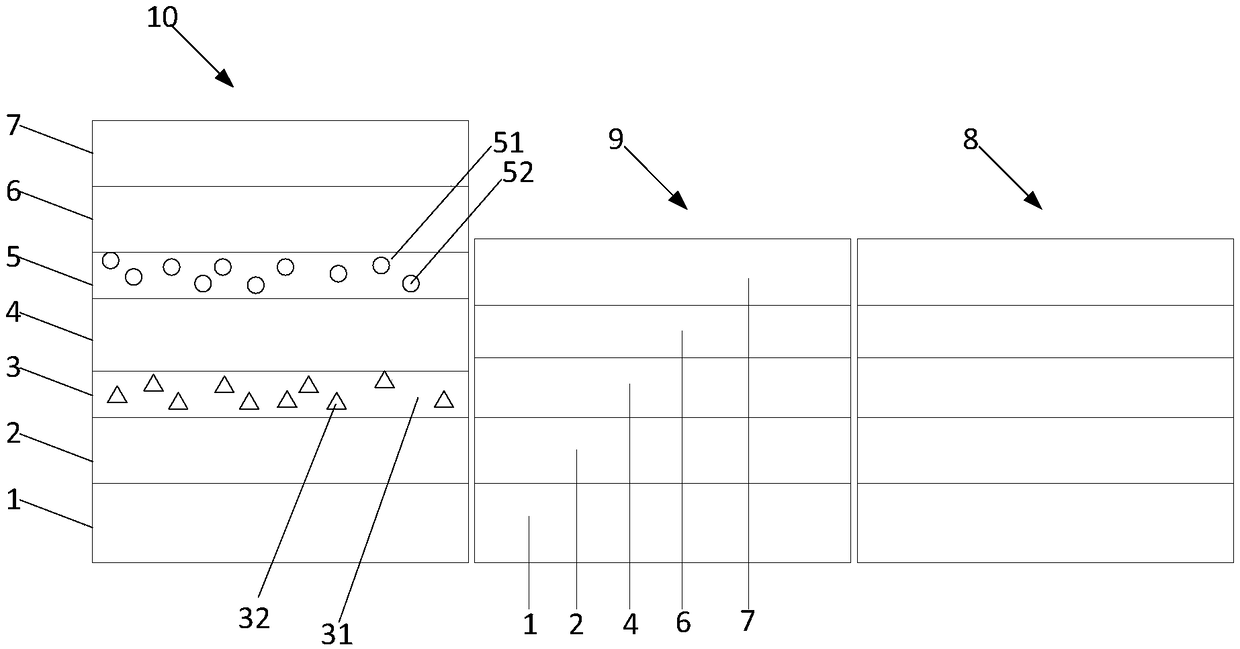

[0059] The embodiment of the present invention also provides an organic electroluminescent device, including several pixel units distributed in an array, such as image 3 As shown, each pixel unit includes a red light sub-pixel unit 8, a green light sub-pixel unit 9, and a blue light sub-pixel unit 10, and each sub-pixel unit includes a stacked first electrode layer 1, a light emitting layer 4, and a second electrode Layer 7, the light-emitting layer 4 in the red sub-pixel unit 8, the green sub-pixel unit 9 and the blue sub-pixel unit 10 is a red light-emitting layer, a green light-emitting layer and a blue light-emitting layer respectively;

[0060] The blue sub-pixel unit 10 is the organic electroluminescence device provided in the first embodiment above. The specific content has been described in detail in Embodiment 1, and will not be repeated here.

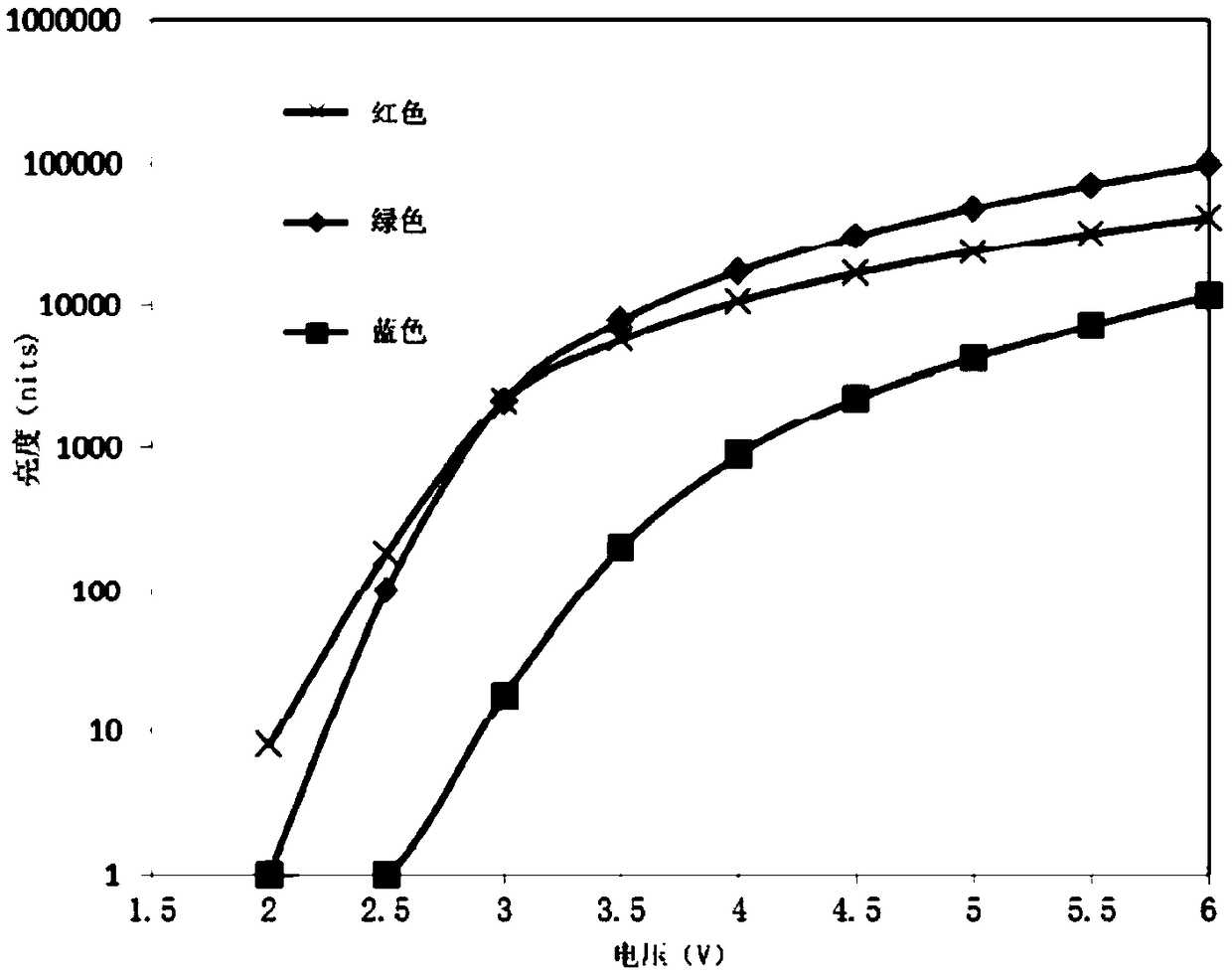

[0061] Generally, the turn-on voltage of the blue sub-pixel unit 10 is greater than the turn-on voltage of the red sub-pix...

Embodiment 3

[0065] The embodiment of the present invention provides a specific organic electroluminescent device, including several pixel units distributed in an array, and each pixel unit includes a red sub-pixel unit 8 , a green sub-pixel unit 9 and a blue sub-pixel unit 10 .

[0066] Each sub-pixel unit includes a stacked first electrode layer 1 (anode), a first carrier functional layer 2 (electron blocking layer), a light emitting layer 4, a second carrier functional layer 6 (hole blocking layer) ) and the second electrode layer 7 (cathode), the light-emitting layer 4 in the red sub-pixel unit 8, the green sub-pixel unit 9 and the blue sub-pixel unit 10 is a red light-emitting layer, a green light-emitting layer and a blue light-emitting layer respectively.

[0067]Wherein, a P-doped layer 3 is disposed between the electron blocking layer and the blue light emitting layer in the blue light sub-pixel unit 10 . The P-doped layer 3 includes the first base material TPD and the P-dopant ND...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com