Adaptive Robust Predictive Control Method for Blast Furnace Hot Metal Quality Based on Lazy Learning

An adaptive and robust technology for blast furnace molten iron, used in adaptive control, general control systems, control/regulation systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

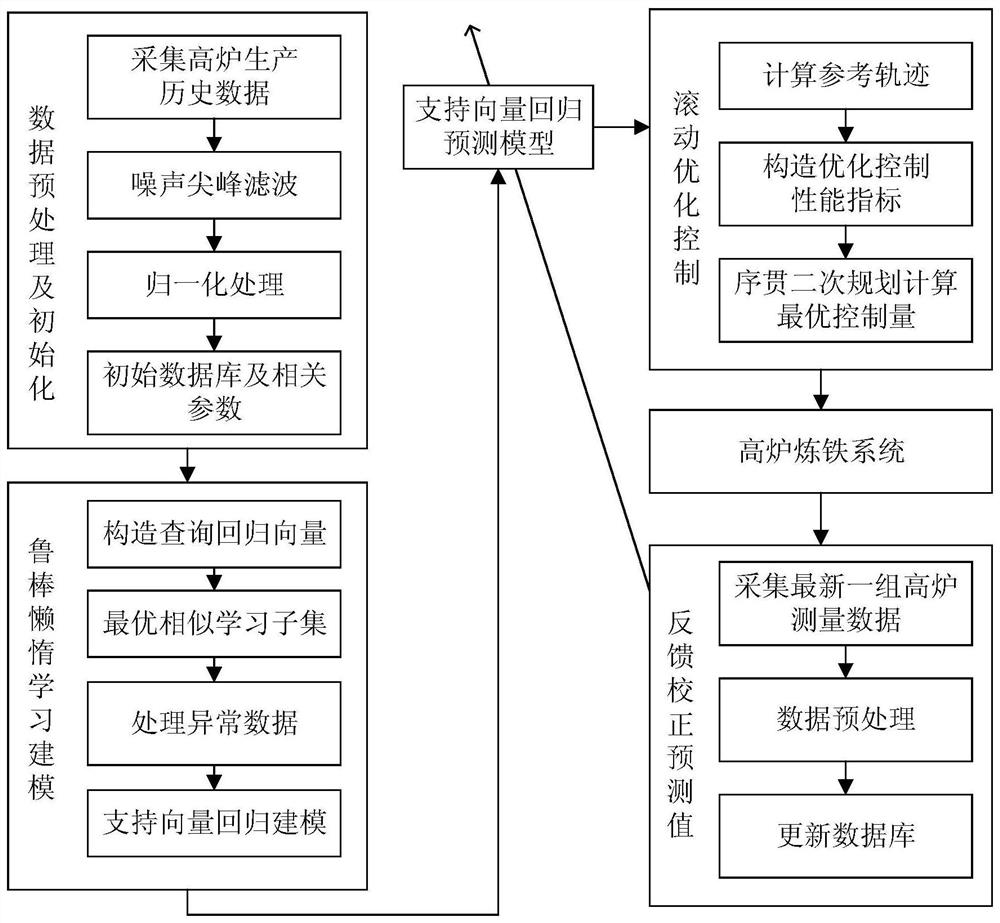

Method used

Image

Examples

Embodiment Construction

[0050] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

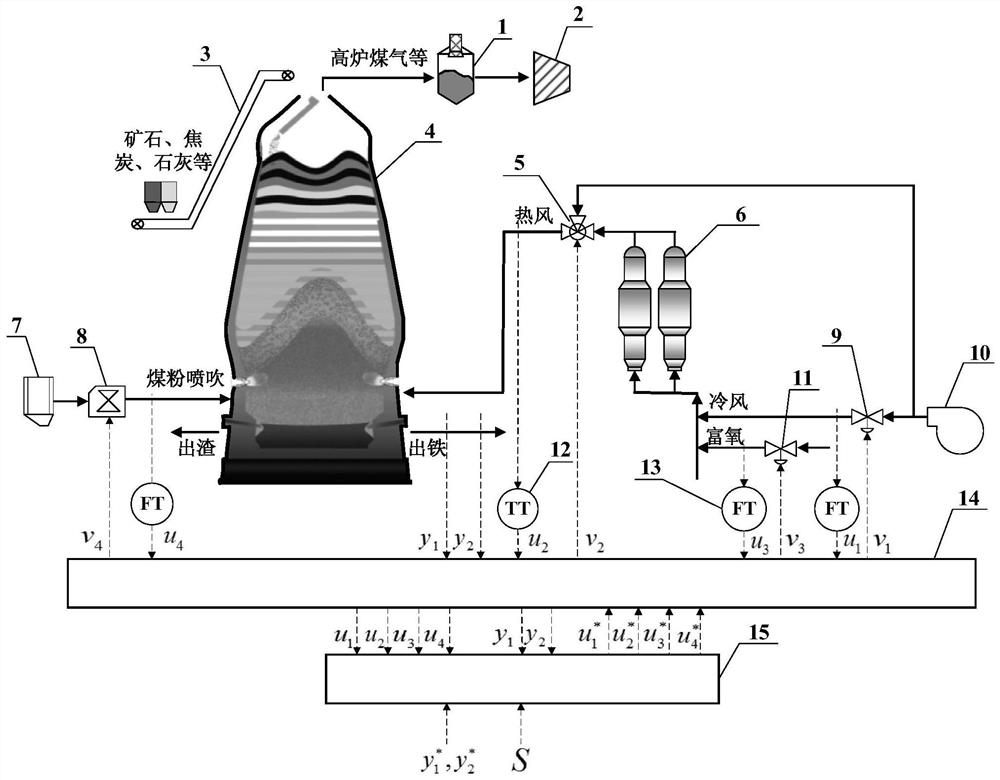

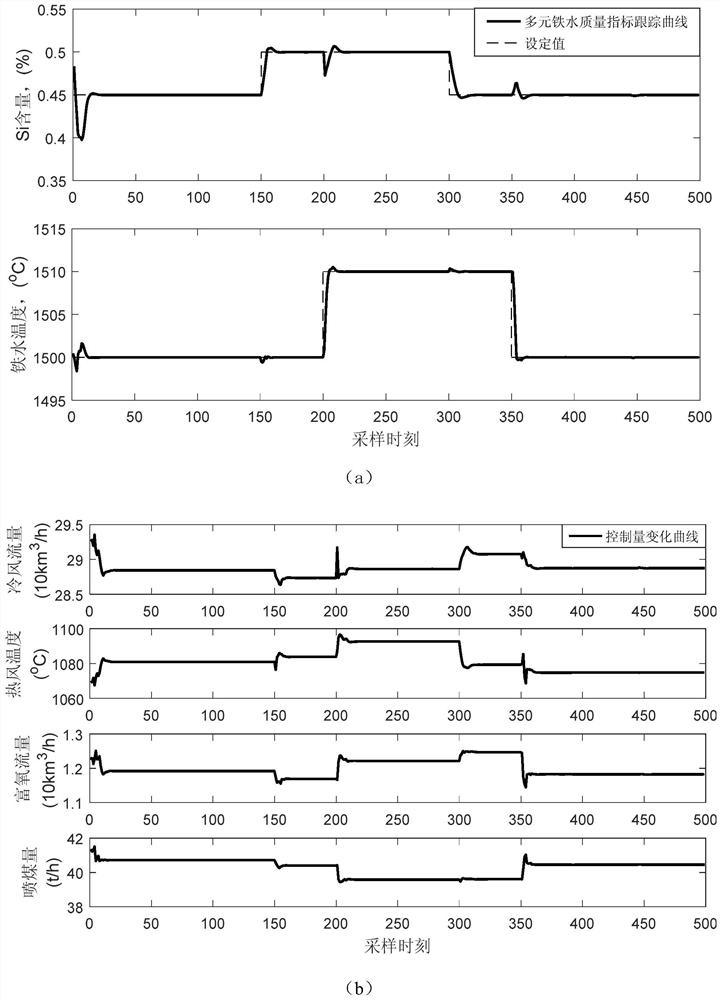

[0051] Take a volume of Liuzhou Steel as 2600m 3 Taking the iron-making blast furnace object as an example, a method for adaptive robust predictive control of blast furnace molten iron quality based on lazy learning provided by the present invention is applied. The current iron-making blast furnace object is installed with the following conventional measurement systems, including: differential pressure flowmeter for measuring cold air flow, balance flowmeter for measuring oxygen-enriched flow, infrared thermometer for measuring hot air temperature, for measuring Pulverized coal flow meter for pulverized coal injection; and the following actuators: flow regulating valve fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com