A fixture device for biaxial loading test of sub-frame

A test fixture and shaft loading technology, which is applied in the automotive field, can solve problems such as test troubles, offsets and cuts, shaking, etc., and achieve the effects of saving installation and clamping time, improving test efficiency, and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

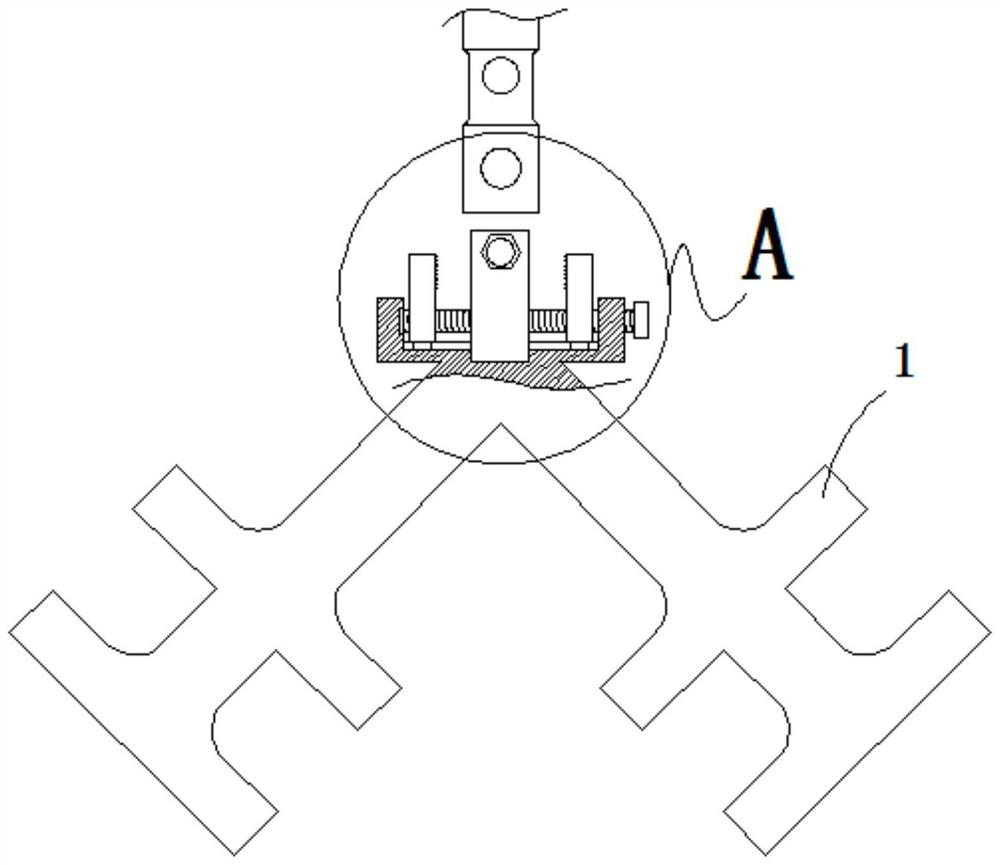

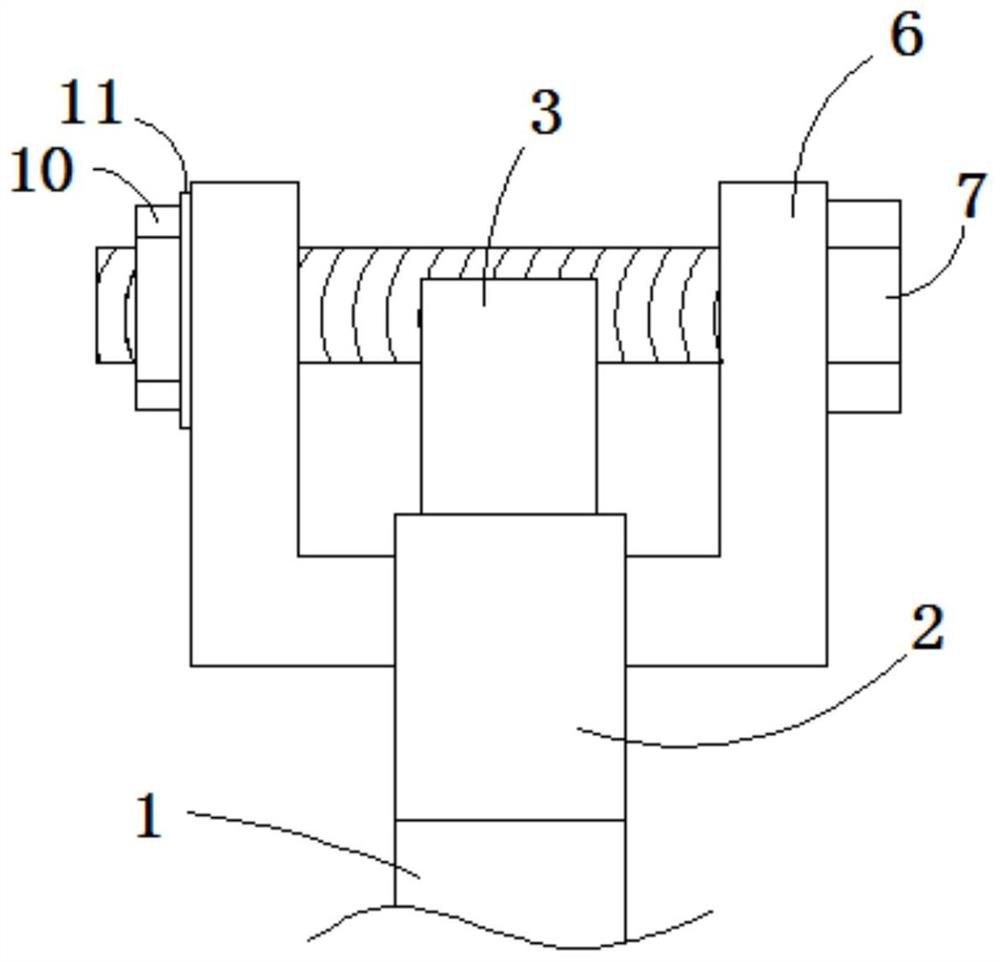

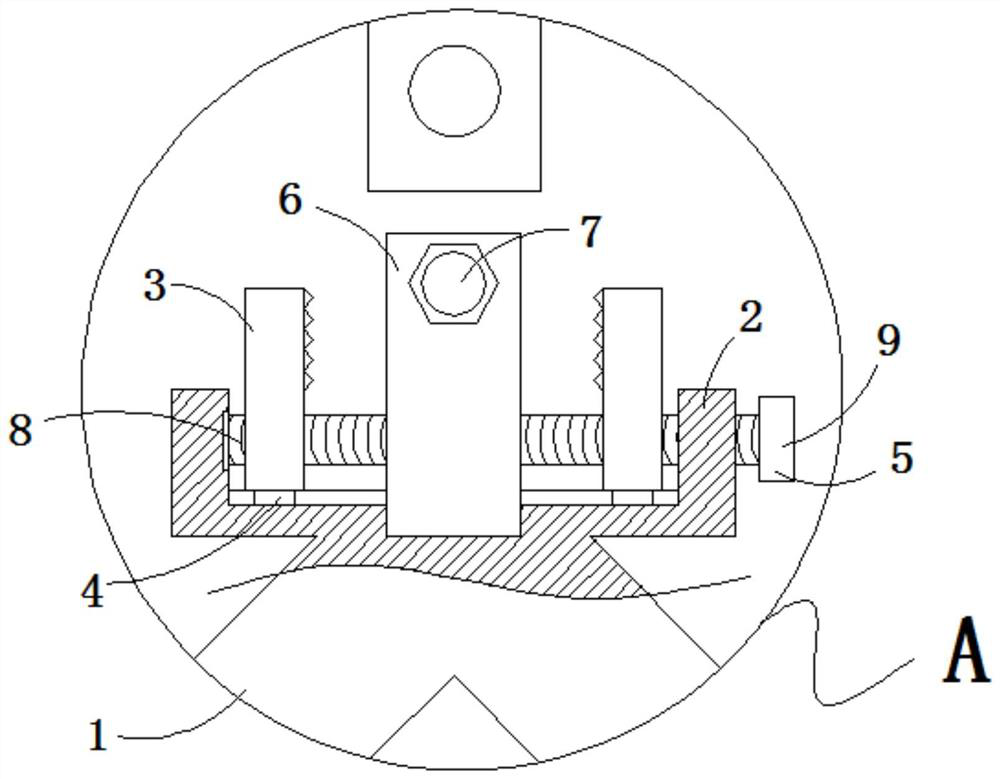

[0022] refer to Figure 1-3 , a fixture device for a sub-frame biaxial loading test, comprising a fixture body 1, the fixture body 1 is made of stainless steel, and the fixture body 1 has undergone a quenching process, thereby prolonging the service life and reducing the risk of fracture during the test, the fixture body A U-shaped block 2 is fixedly connected to the right angle of 1, and two clamping blocks 3 are arranged in the U-shaped block 2, and sawtooth grooves are provided on the sides of the two clamping blocks 3 that are close to each other, which increases the stability of the clamping. One clamp block 3 is fixedly connected with a slide block 4 near the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com