Excavation method for middle and lower portion of underground cavern in high-crustal-stress area

A technology of underground caverns and high ground stress, which is applied in the field of underground engineering construction and blasting excavation to achieve the effect of reducing local stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in combination with specific embodiments. The specific embodiments are further explanations of the principles of the present invention and do not limit the present invention in any way. The same or similar technologies as the present invention do not exceed the protection scope of the present invention.

[0022] Combined with the drawings.

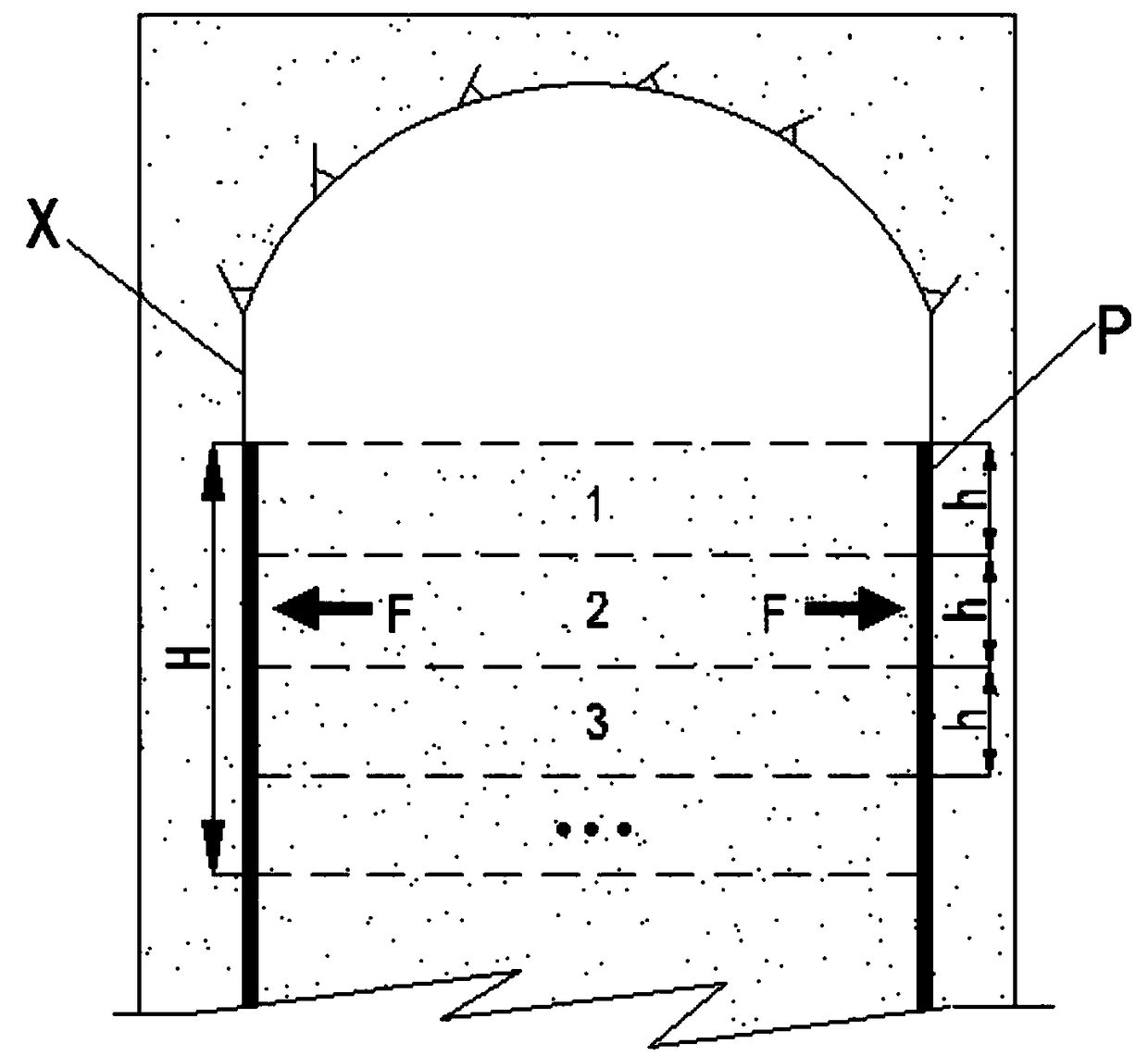

[0023] The method of excavating the middle and lower parts of underground caverns in high ground stress areas includes the following steps:

[0024] After the excavation of the top of the cavern is completed, excavate the middle and lower parts of the cavern in layers from top to bottom;

[0025] Before excavation, deep-hole pre-splitting blasting is carried out along the structural line of the side wall of the cavern to form a deep blasting pre-crack. The depth of the blasting pre-crack is 3 to 5 times the thickness of the layered blasting step;

[0026] One week after the formation of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole depth | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com