A construction method of pre-buried light guide hole

A construction method and technology of light guide holes, which are applied in the field of formwork/formwork/work frame, construction components on-site preparation, construction, etc., can solve the problem of mutual influence, the large deviation of the adjustment value of the inner mold in the light guide hole, etc. problems, to reduce the difficulty of calibration, improve the quality of pre-embedding, broad promotion and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

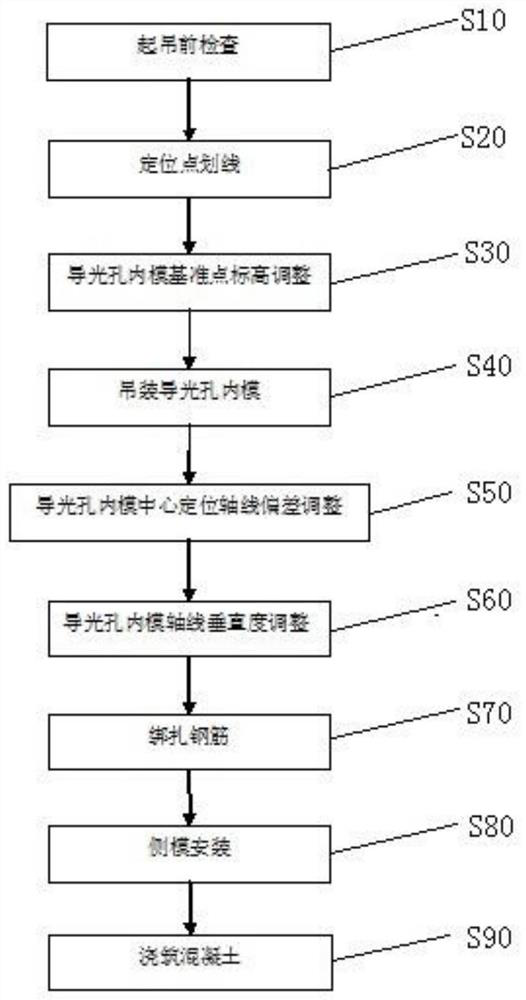

Method used

Image

Examples

Embodiment

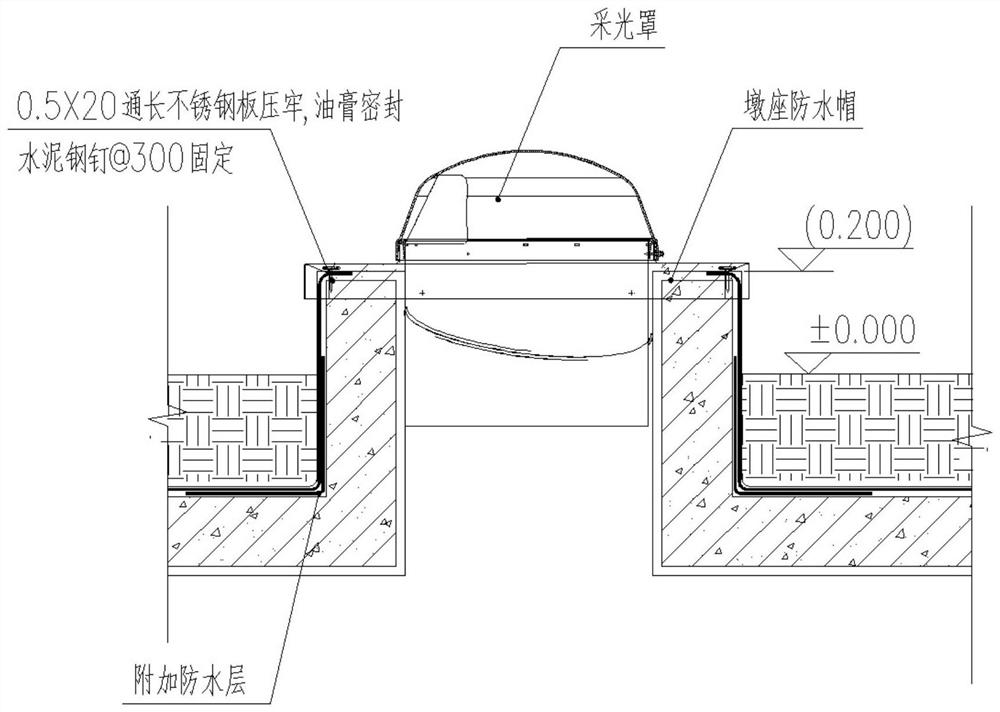

[0051] The embodiment of the present invention is the general contracting (main structure) of the late-stage engineering project of the software industry centralized incubation center (Phase III) in the core area of Guangzhou Tianhe Smart City-Software Park Gaotang New Area. The construction area of this project is about 72847 square meters. The main functions are office, exhibition, restaurant, parking lot, etc. Concrete frame-shear wall structure is adopted, the typical column network is 8.4mx8.4m, and the steel-concrete composite structure is used in some large-span areas. There are 10 floors above ground and 4 floors underground, and the excavation depth of the basement is about 14.5m.

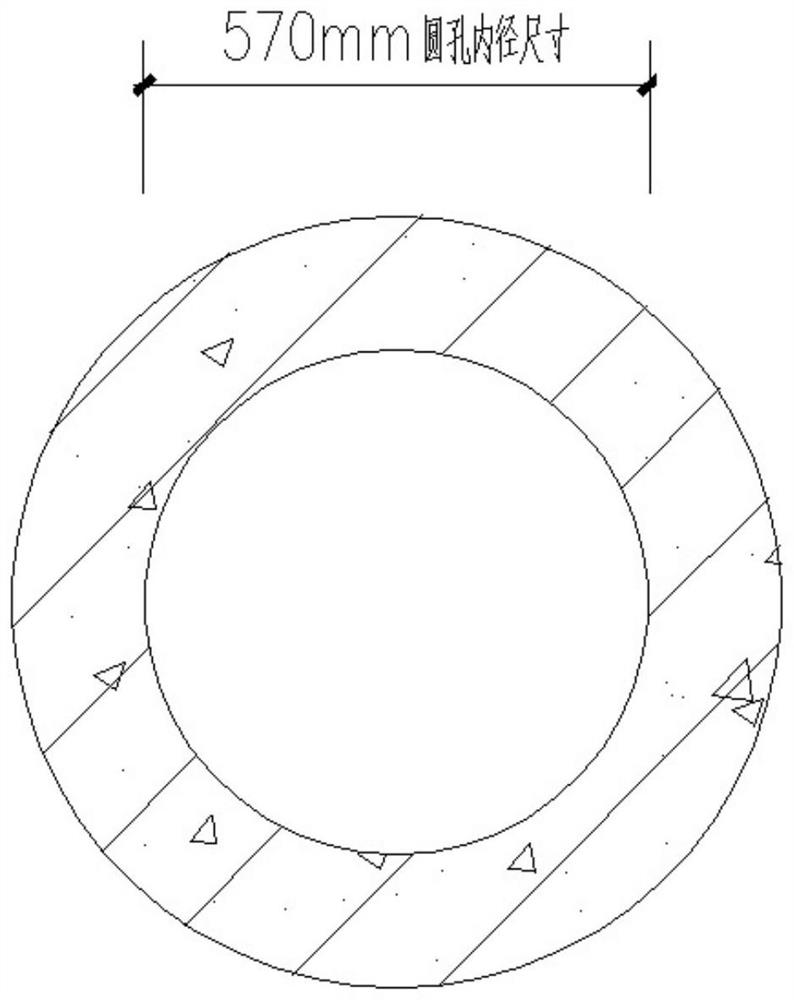

[0052] The underground garage on the first floor of this project adopts light pipe lighting system in 37 locations. The light pipe lighting system adopts the form of a hemispherical light collector, the pipe diameter adopts the specification of 530mm, the installation base is 200mm h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com