New connection joints and construction methods for metal wall panels in clean rooms

A technology for connecting joints and construction methods, applied in the processing of building materials, construction, building construction, etc., can solve the problems that structural adhesives are difficult to meet the rigidity requirements of metal siding, joint deformation and cracking, etc., and reduce the time for degassing and purification. , good airtightness, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

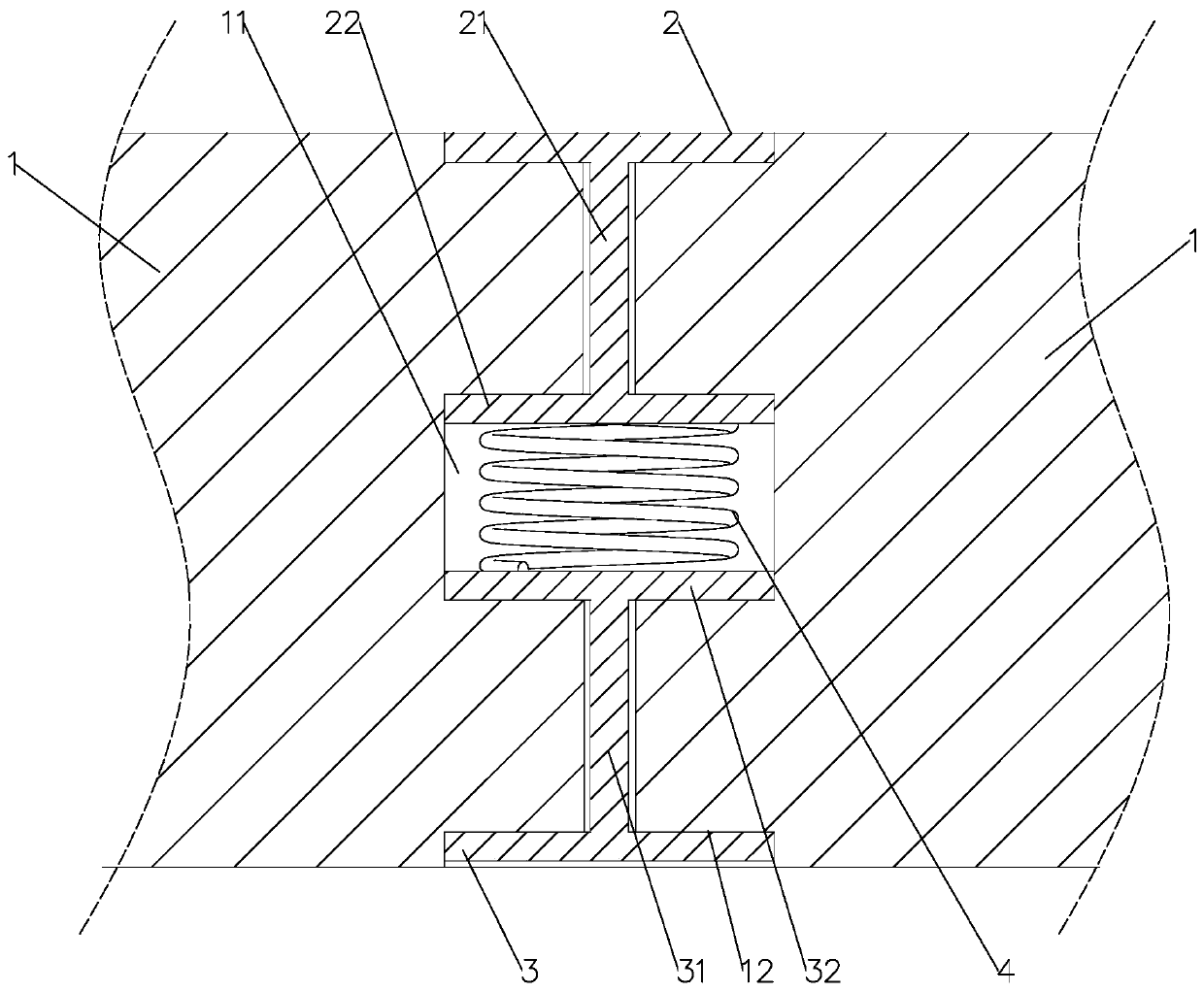

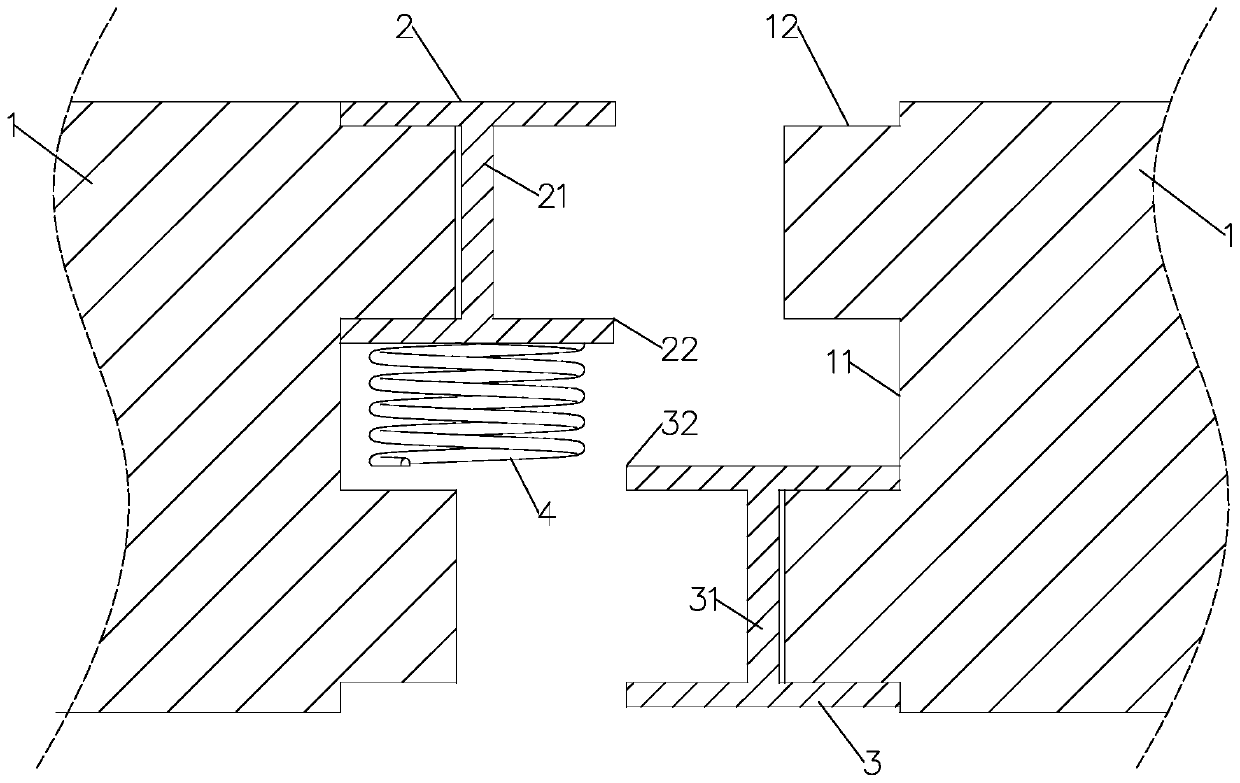

Image

Examples

Embodiment 1

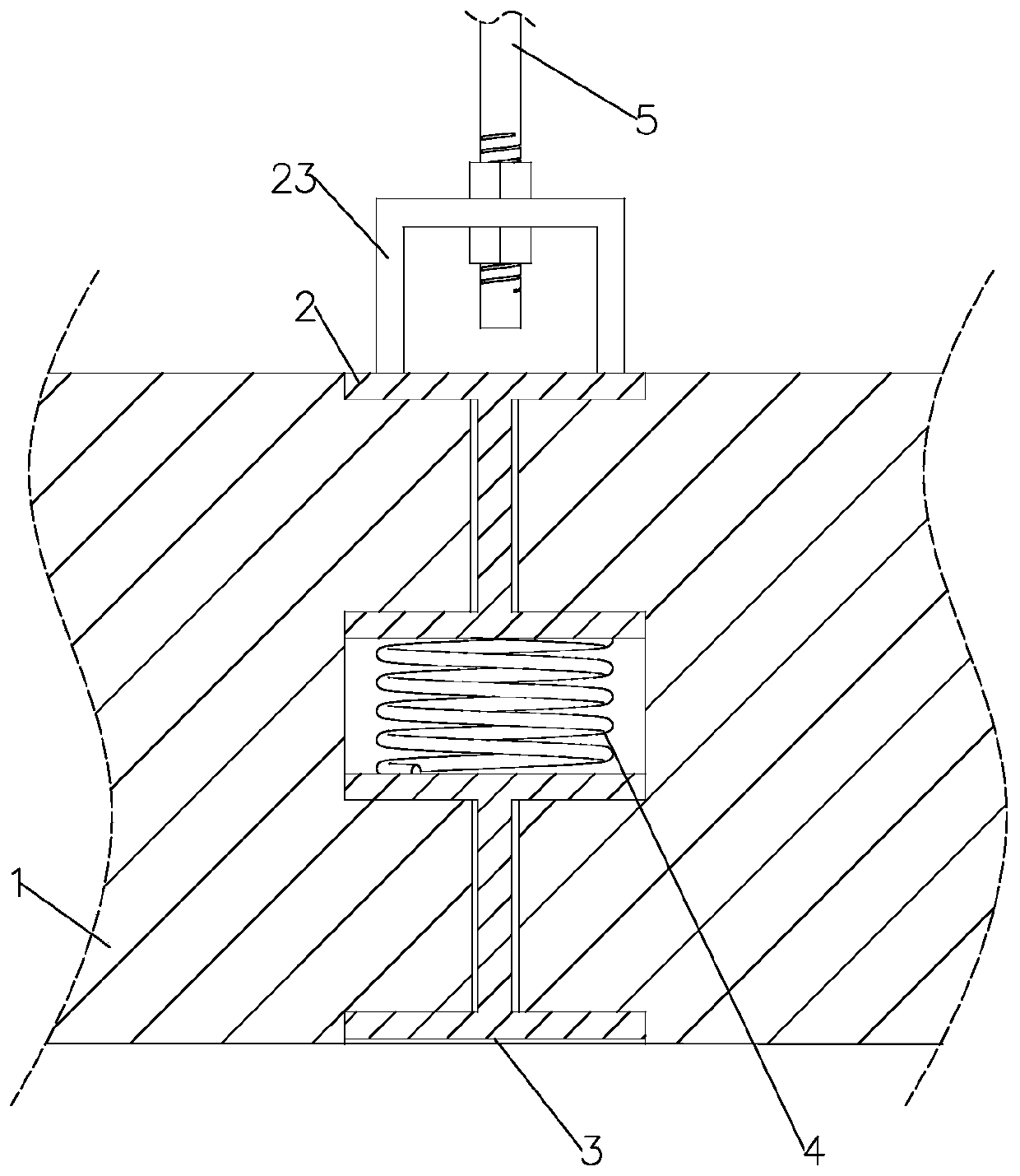

[0054] refer to image 3 , in step 5 also includes the fixed installation of the inserting strips, a number of lifting lugs 23 are provided on the side of the inner cover plate 2 away from the outer cover plate 3, and the lifting lugs 23 are arranged along the length direction of the inner cover plate 2, in this embodiment The middle lug 23 is installed on the ceiling of the clean room through the anchor rod 5, and the anchor rod 5 is vertically anchored on the ceiling. Wherein, the lifting lug 23 is a U-shaped plate with the opening facing down, which is fixed on the inner cover plate 2 by welding the two ends of the opening, and the anchor rod 5 passes through the bottom plate of the lifting lug 23 to connect with it. A nut is provided to lock and fix it.

Embodiment 2

[0056] refer to Figure 4 In this embodiment, the lifting lug 23 is installed on the wall of the clean room through the anchor rod 5, and the anchor rod 5 is horizontally anchored on the ceiling. Wherein, the lifting ear 23 is a U-shaped plate with the opening facing downward, which is fixed on the inner cover plate 2 by welding the side plate on one side, and the anchor rod 5 passes through the other side plate of the lifting ear 23 to be connected with it, and the lifting ear 23 A nut is respectively arranged on the inner and outer sides to lock and fix it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com