Visible-light responsive hafnium-based metal-organic framework material and preparation method thereof

An organic framework and base metal technology, which is applied in the field of preparation of visible light-responsive hafnium-based metal-organic framework materials, can solve the problems of narrow light absorption band and poor stability, and achieves good repeatability, high thermal and chemical stability, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

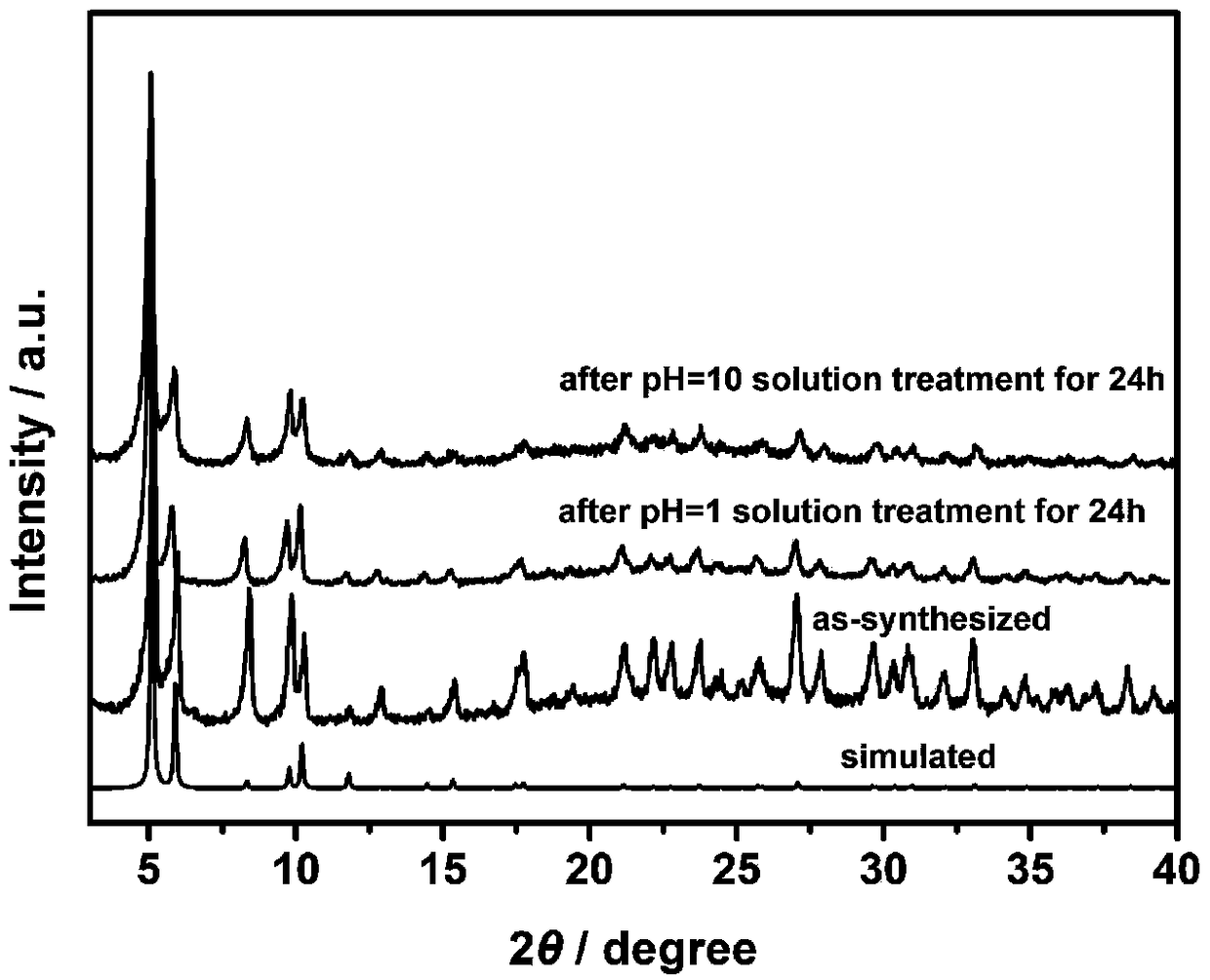

[0018] Preparation of new hafnium-based metal-organic framework materials: Weigh 0.067mmol HfCl 4 , 0.067mmol trans-ethylene bisaminobenzoic acid was added to a 15mL polytetrafluoroethylene reactor lining, 400μL glacial acetic acid and 3mL N,N'-dimethylformamide (DMF) were added to the reactor lining, and stirred at room temperature After 30 minutes, the reactor was transferred to an oven at 100°C and heated for 96 hours to obtain orange-red octahedral block crystals; the crude porous hafnium-based metal-organic framework was washed with DMF and ethanol and dried at 80°C to obtain purified The hafnium-based metal-organic framework material has a yield of 80% (calculated based on the dosage of the organic ligand trans-ethylene bisaminobenzoic acid).

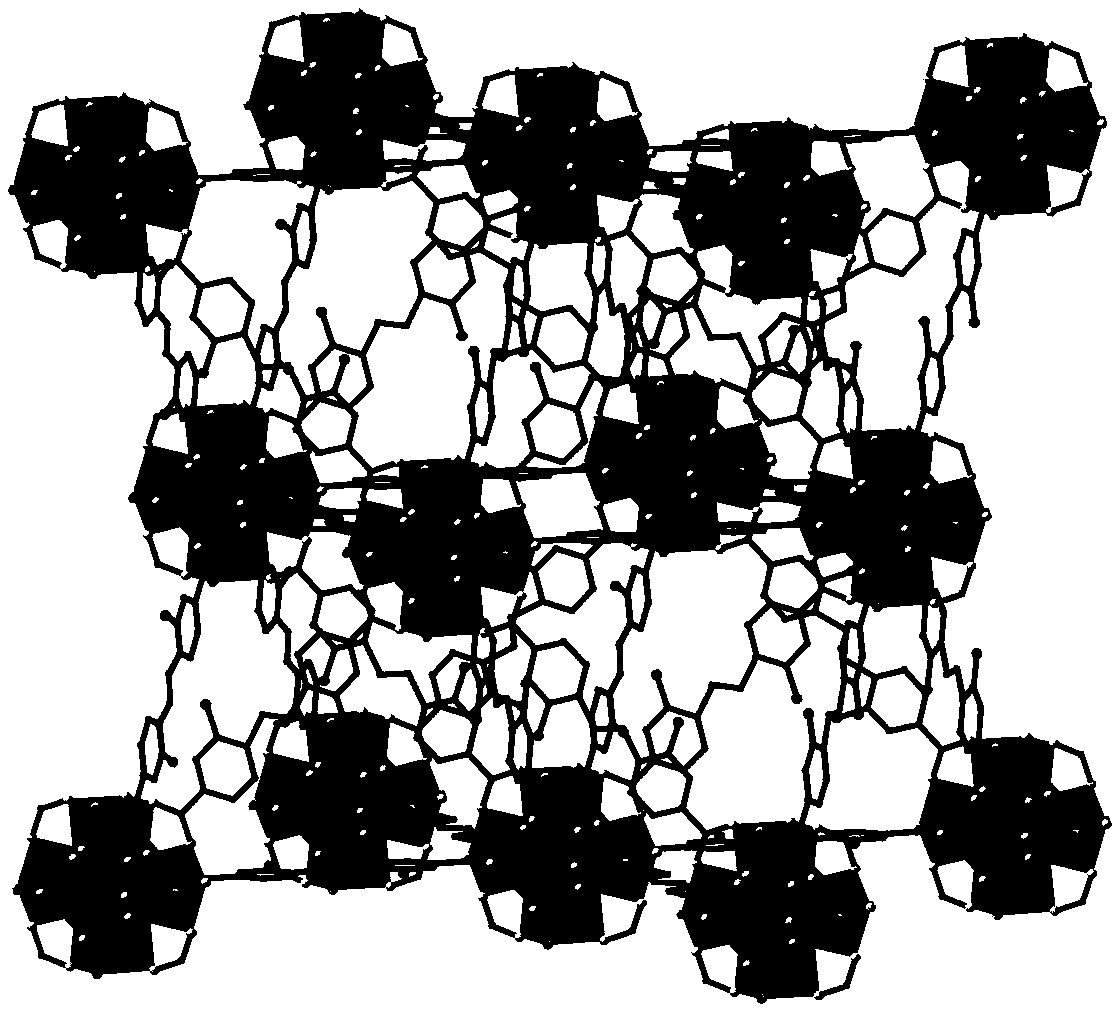

[0019] The hafnium-based metal-organic framework material belongs to the cubic crystal system, the space group Fm-3m, and the unit cell parameters are 29.868, 29.868, 29.868, 90.00, 90.00, and 90.00. Cell volume:

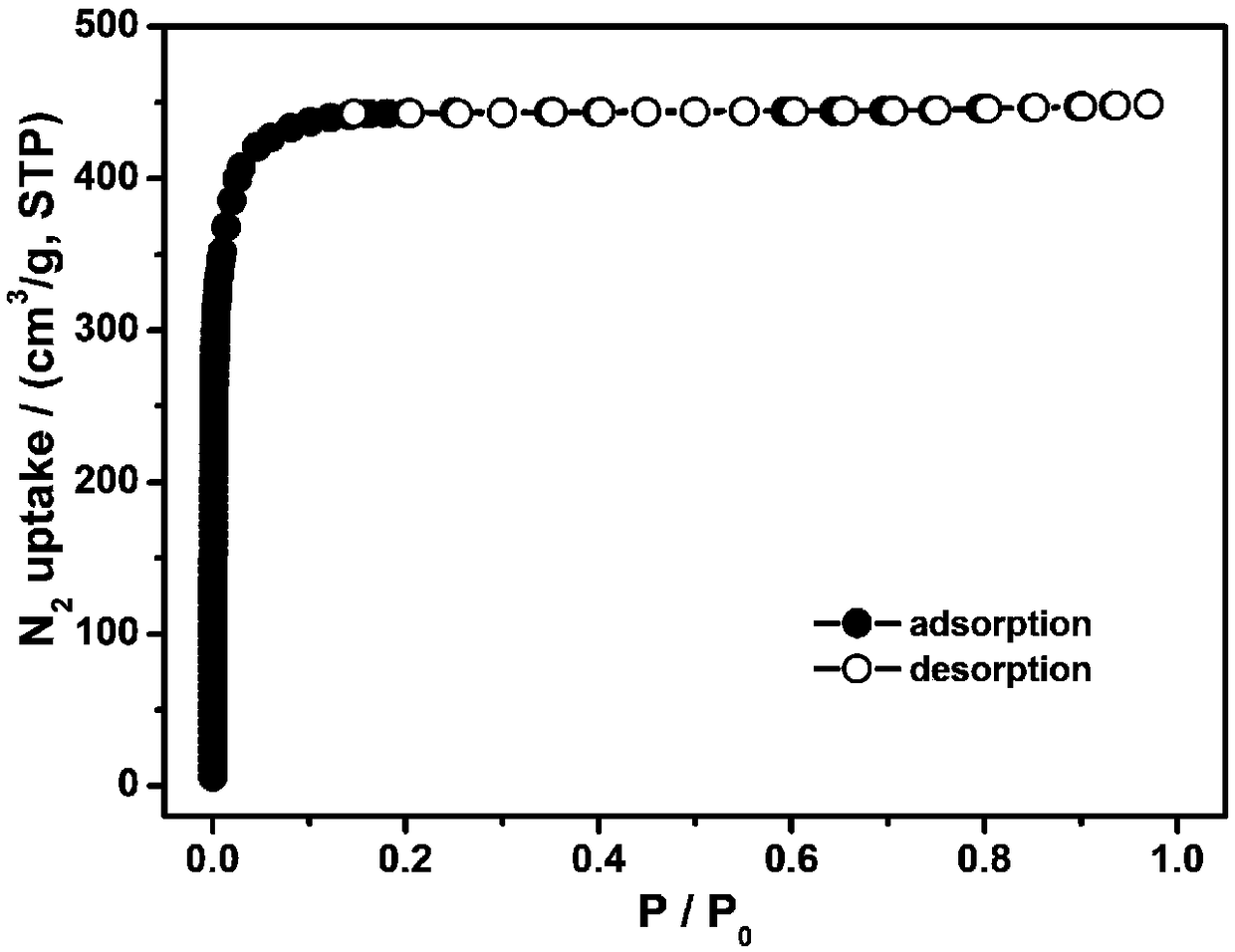

[0020] The ...

Embodiment 2

[0025] Using 100 μL of glacial acetic acid instead of 400 μL of glacial acetic acid in Example 1, repeating the experiment of Case 1, an orange-red octahedral block crystal was obtained, which was washed and dried with DMF and absolute ethanol to obtain a purified porous hafnium-based metal-organic framework material. The yield is 75% (calculated based on the dosage of organic ligand trans-ethylene bisaminobenzoic acid).

Embodiment 3

[0027] Using 800 μL of glacial acetic acid instead of 400 μL of glacial acetic acid in Example 1, repeating the experiment of Case 1, an orange-red octahedral block crystal was obtained, which was washed and dried with DMF and absolute ethanol to obtain a purified porous hafnium-based metal-organic framework material. The yield is 50% (calculated based on the dosage of the organic ligand trans-ethylene bisaminobenzoic acid).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com