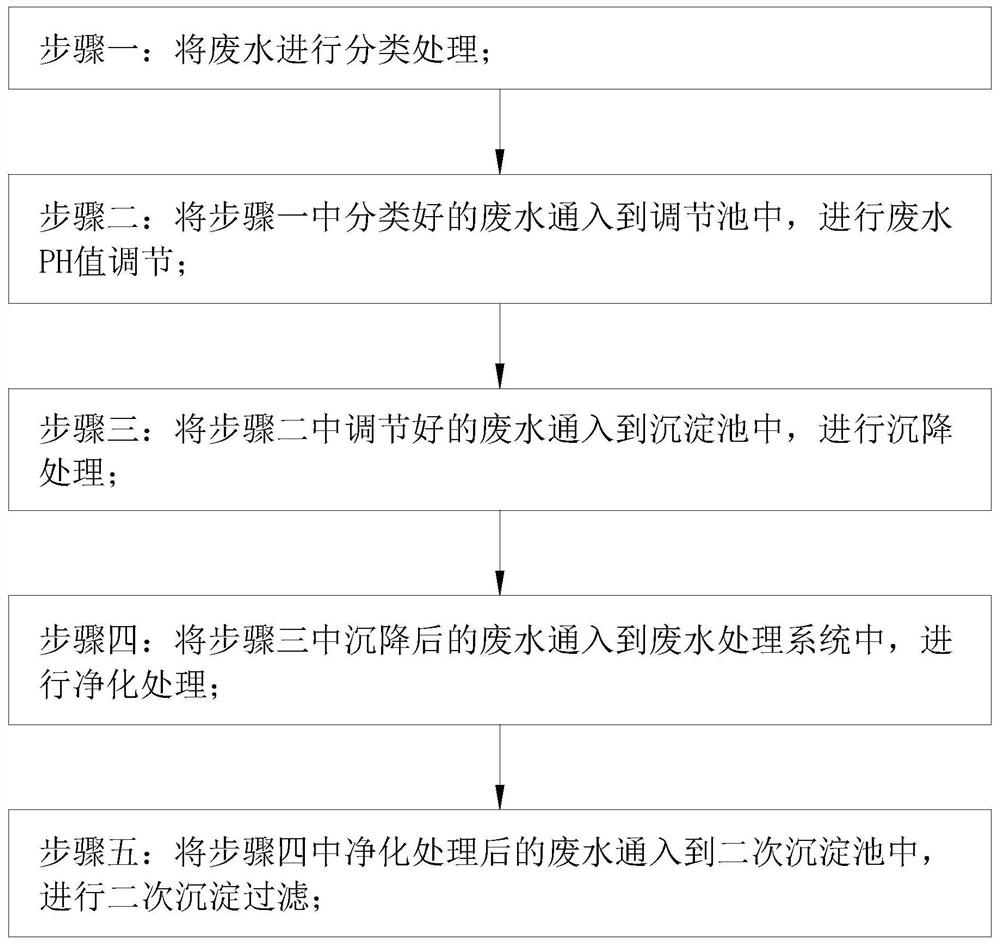

A method for purifying and treating wastewater from coal chemical industry

A coal chemical wastewater purification treatment technology, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of increasing the collision area between flocculants and impurities in wastewater, insufficient stirring, etc. , to increase the air pressure, improve the utilization rate, and improve the effect of spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

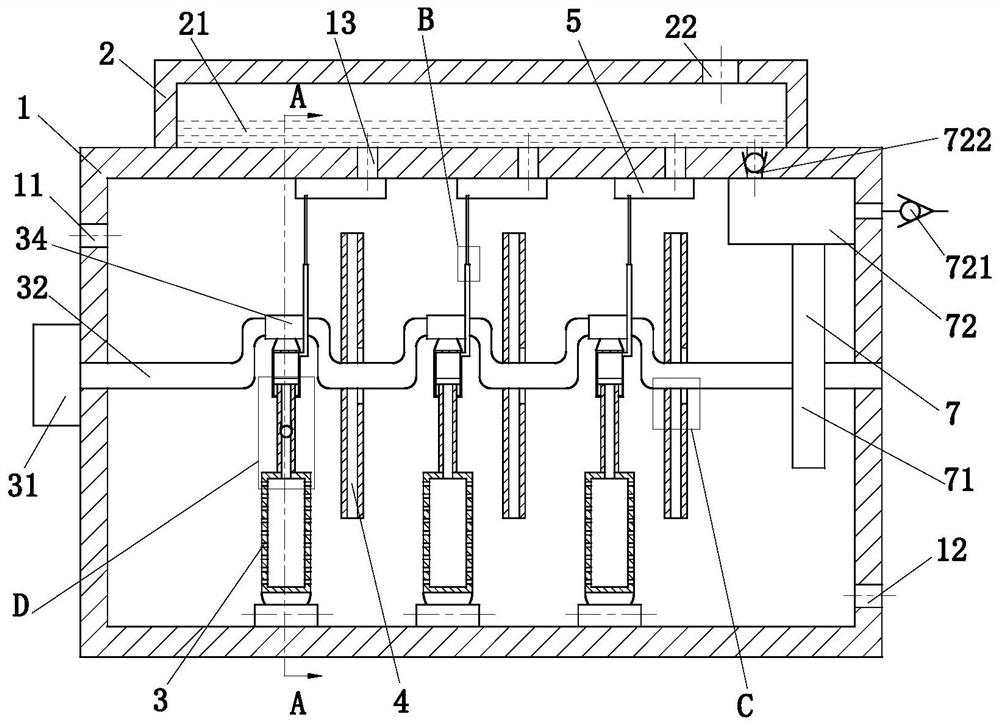

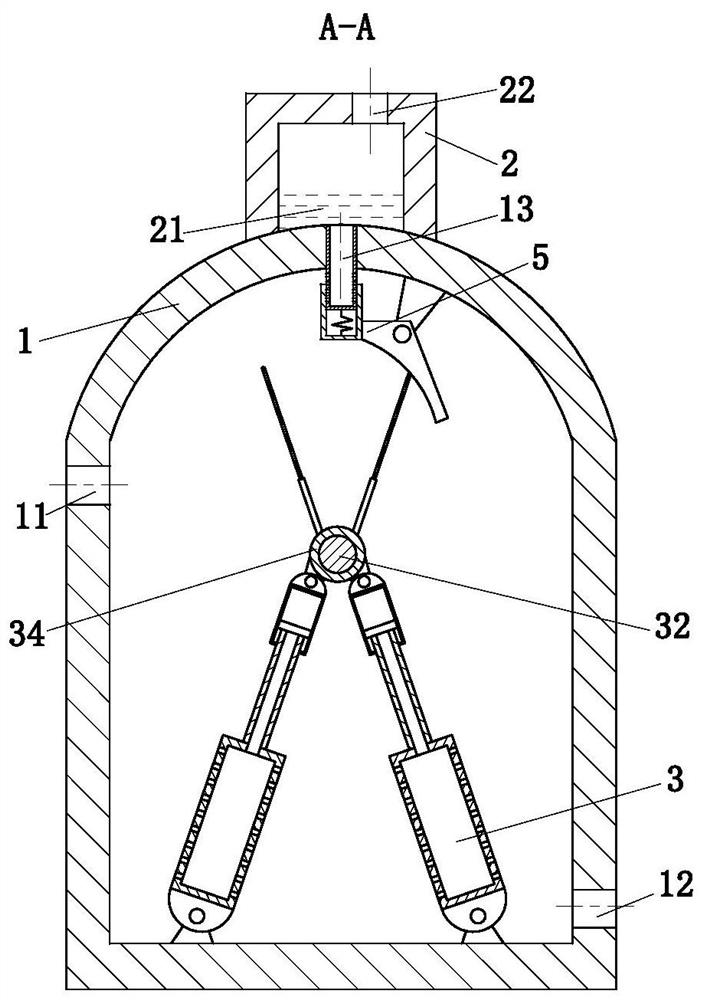

[0052] As an embodiment of the present invention, the control element 38 is a No. 1 one-way valve 381 .

[0053] The flocculant 21 is sprayed into the treatment tank 1, and the flocculant 21 and the waste water are dissolved. When the drive motor 31 drives the crankshaft 32 to rotate, the rotating block 34 pulls the piston cylinder 35 to move to the side close to the crankshaft 32, and the piston cylinder 35 moves toward the first Pipe 36 jets, because the No. 1 pipe 36 is provided with No. 1 check valve 381, No. 1 check valve 381 is used for one-way gas supply to treatment tank 1, simultaneously in order to prevent waste water from being sucked into No. 1 case 33, waste water is not Fully dissolve with the flocculant 21, thereby affecting the purification effect; the gas ejected from the piston cylinder 35 is ejected from the gas injection port 331, and the gas action accelerates the dissolution efficiency of the flocculant 21 and the waste water, thereby improving the purific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com