MNx super crystal and preparing method and application thereof

A crystalline, super technology, applied in the preparation of sulfide/polysulfide, binary selenium/tellurium compounds, metal selenide/telluride, etc. problem, to achieve the effect of low preparation cost, uniform size and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

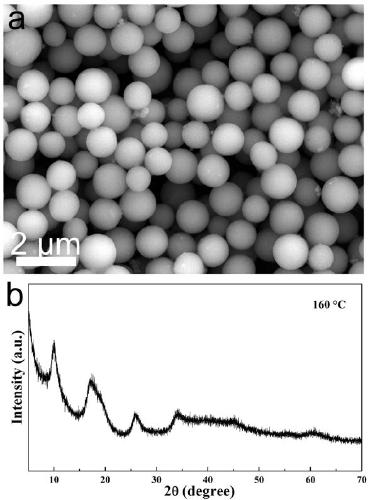

[0037] A kind of MN in this embodiment x The preparation method of the super crystal is as follows:

[0038] (1) Weigh 12 mmol of Sapamine A cationic surfactant, add 100 mL of n-butanol, and ultrasonically dissolve for 30 minutes to form a uniform oil phase solution;

[0039] (2) Weigh 0.8 mmol sodium molybdate, add 300 mL deionized water, and ultrasonically dissolve for 10 min to form a uniform and stable aqueous solution;

[0040] (3) With vigorous stirring at room temperature, add the sodium molybdate aqueous phase solution dropwise to the Sapamine A oil phase solution, stir vigorously for 2 h after adding the aqueous phase solution, and then add 50 mL of ethylene glycol dropwise to the mixed solution alcohol, stirred vigorously for 10 min, added 1 mL of hydrochloric acid dropwise to the mixed solution, stirred vigorously for 1 h, then added 6 mmol (0.4567 g) thiourea dropwise to the mixed solution, stirred vigorously for 3 h, until the solution was uniform, stable emulsi...

Embodiment 2

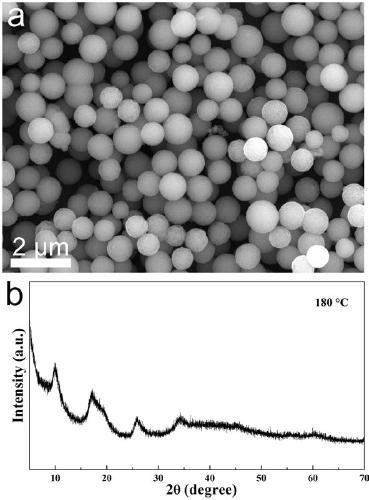

[0044] A kind of MN in this embodiment x The preparation method of the super crystal is as follows:

[0045] (1) Weigh 12 mmol of Ahcovel A cationic surfactant, add 100 mL of n-butanol, and ultrasonically dissolve for 30 minutes to form a uniform oil phase solution;

[0046] (2) Weigh 0.8 mmol sodium molybdate, add 300 mL deionized water, and ultrasonically dissolve for 10 min to form a uniform and stable aqueous solution;

[0047] (3) In the state of vigorous stirring at room temperature, the sodium molybdate aqueous phase solution was added dropwise to the Ahcovel A oil phase solution. After adding the aqueous phase solution, stirred vigorously for 2 h, and then added 50 mL of ethylene glycol dropwise to the mixed solution. Stir vigorously for 10 min, add 1 mL of hydrochloric acid dropwise to the mixed solution, and after stirring vigorously for 1 h, add 6 mmol (0.4567 g) thiourea dropwise to the mixed solution, stir vigorously for 3 h, until the solution forms a uniform, s...

Embodiment 3

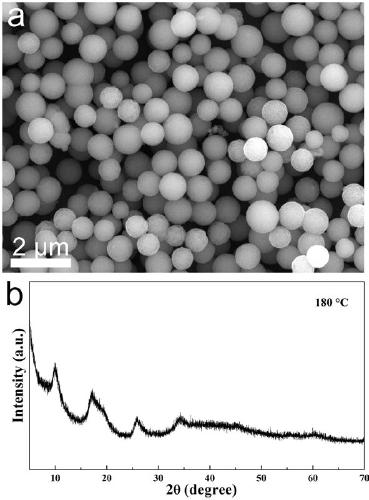

[0051] A kind of MN in this embodiment x The preparation method of the super crystal is as follows:

[0052] (1) Weigh 12 mmol of CTAB cationic surfactant, add 100 mL of n-butanol, and ultrasonically dissolve for 30 min to form a uniform oil phase solution;

[0053] (2) Weigh 0.8 mmol sodium molybdate, add 300 mL deionized water, and ultrasonically dissolve for 10 min to form a uniform and stable aqueous solution;

[0054] (3) Under the state of vigorous stirring at room temperature, add the sodium molybdate aqueous phase solution dropwise to the CTAB oil phase solution, stir vigorously for 2 h after adding the aqueous phase solution, add 50 mL ethylene glycol dropwise to the mixed solution, and vigorously Stir for 10 min, add 0.09 mL hydrochloric acid dropwise to the mixed solution, stir vigorously for 1 h, add 6 mmol (0.4567 g) thiourea dropwise to the mixed solution, stir vigorously for 3 h, until the solution forms a uniform and stable emulsion ;

[0055] (4) Put the em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com