Composite PE (polyethylene) film for printing and preparation method of PE film

A polyethylene film and melt index technology, applied in the field of polyethylene film, can solve the problems of low surface free energy, reduced heat-sealing performance of polyethylene film, and poor aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

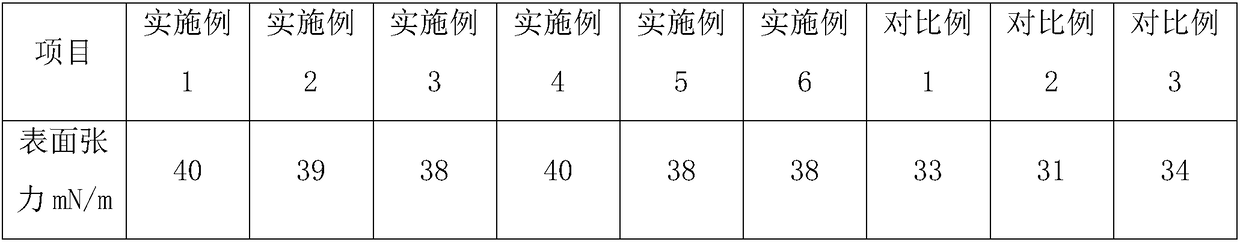

Examples

Embodiment 1

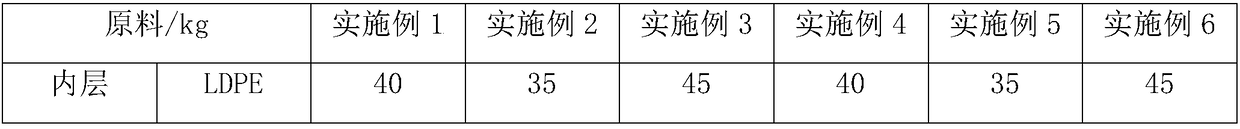

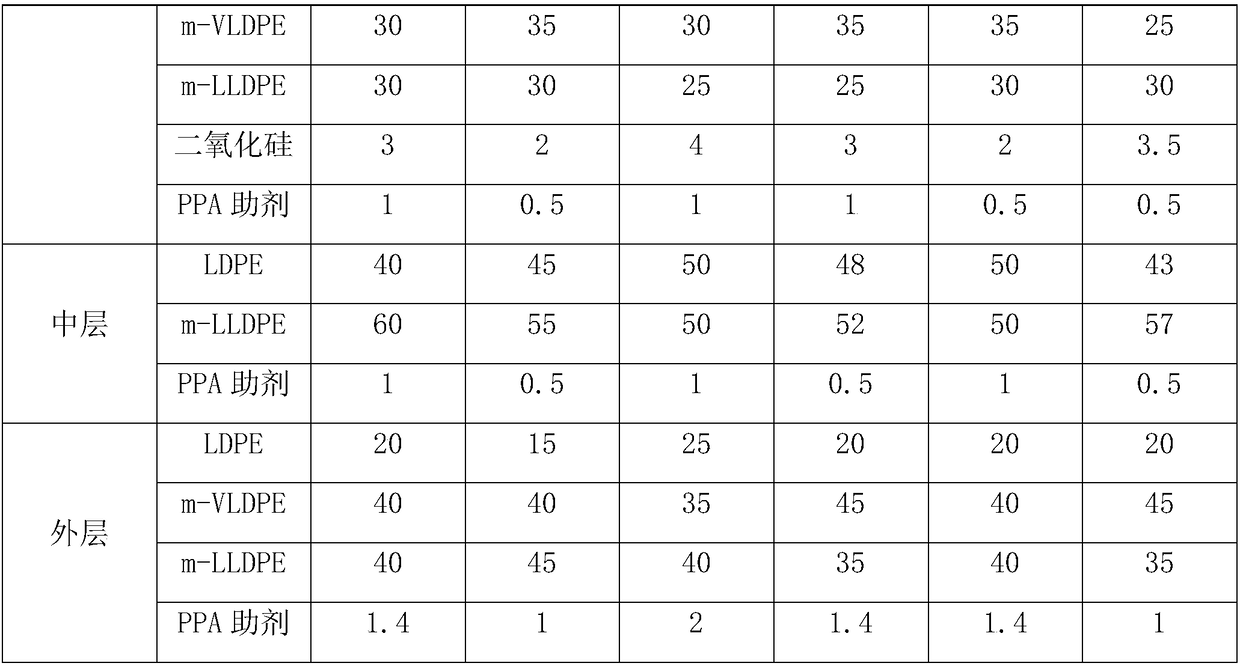

[0046] Embodiment 1: A kind of polyethylene film for printing composite is prepared by the following method:

[0047] (1) Ingredients: A: Inner layer raw materials include 40kg with a melt index of 1.9g / 10min and a density of 0.924g / cm 3 LDPE, 30kg melt index is 2.0g / 10min, density is 0.918g / cm 3 m-VLDPE, 30kg melt index is 1.0g / 10min, density is 0.918g / cm 3 m-LLDPE, 3kg of silica blocking agent with a particle size of 4-5μm and 1kg of PPA additive;

[0048] B: The middle layer raw material includes 40kg with a melt index of 1.9g / 10min and a density of 0.924g / cm 3 LDPE, 60kg melt index is 1.0g / 10min, density is 0.918g / cm 3 m-LLDPE and 1kgPPA additives;

[0049] C: Outer layer raw materials include 20kg with a melt index of 1.9g / 10min and a density of 0.924g / cm 3 LDPE, 40kg melt index is 2.0g / 10min, density is 0.918g / cm 3 m-VLDPE, 40kg melt index is 1.0g / 10min, density is 0.918g / cm 3 m-LLDPE and 1.4kgPPA additives;

[0050] Wherein, the interlayer thickness ratio of the...

Embodiment 2

[0056] Embodiment 2: A kind of polyethylene film for printing composite is prepared by the following method:

[0057] (1) Ingredients: A: Inner layer raw materials include 35kg with a melt index of 1.9g / 10min and a density of 0.924g / cm 3 LDPE, 35kg melt index is 2.0g / 10min, density is 0.918g / cm 3 m-VLDPE, 30kg melt index is 1.0g / 10min, density is 0.918g / cm 3 m-LLDPE, 2kg of silica blocking agent with a particle size of 4-5μm and 0.5kg of PPA additive;

[0058] B: The middle layer raw material includes 45kg with a melt index of 1.9g / 10min and a density of 0.924g / cm 3 LDPE, 55kg melt index is 1.0g / 10min, density is 0.918g / cm 3 m-LLDPE and 0.5kgPPA additives;

[0059] C: Outer layer raw materials include 15kg with a melt index of 1.9g / 10min and a density of 0.924g / cm 3 LDPE, 40kg melt index is 2.0g / 10min, density is 0.918g / cm 3 m-VLDPE, 45kg melt index is 1.0g / 10min, density is 0.918g / cm 3 m-LLDPE and 1kgPPA additives;

[0060] Wherein, the interlayer thickness ratio of t...

Embodiment 3

[0066] Embodiment 3: A kind of polyethylene film for printing composite is prepared by the following method:

[0067] (1) Ingredients: A: Inner layer raw materials include 45kg with a melt index of 1.9g / 10min and a density of 0.924g / cm 3 LDPE, 30kg melt index is 2.0g / 10min, density is 0.918g / cm 3 m-VLDPE, 25kg melt index is 1.0g / 10min, density is 0.918g / cm 3 m-LLDPE, 4kg of silica blocking agent with a particle size of 4-5μm and 1kg of PPA additive;

[0068] B: The middle layer raw material includes 50kg with a melt index of 1.9g / 10min and a density of 0.924g / cm 3 LDPE, 50kg melt index is 1.0g / 10min, density is 0.918g / cm 3 m-LLDPE and 1kgPPA additives;

[0069] C: Outer layer raw materials include 25kg with a melt index of 1.9g / 10min and a density of 0.924g / cm 3 LDPE, 35kg melt index is 2.0g / 10min, density is 0.918g / cm 3 m-VLDPE, 40kg melt index is 1.0g / 10min, density is 0.918g / cm 3 m-LLDPE and 2kgPPA additives;

[0070] Wherein, the interlayer thickness ratio of the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com