Method for preparing high-strength corrosion-resistant ductile iron pipe

A corrosion-resistant and high-strength technology, applied in the field of the preparation of ductile cast pipes, can solve the problems of loose and loose cement on the inner wall of pipe fittings, affecting product quality, health effect and efficiency, reducing hollowing and peeling, and improving lining quality. , Guarantee the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

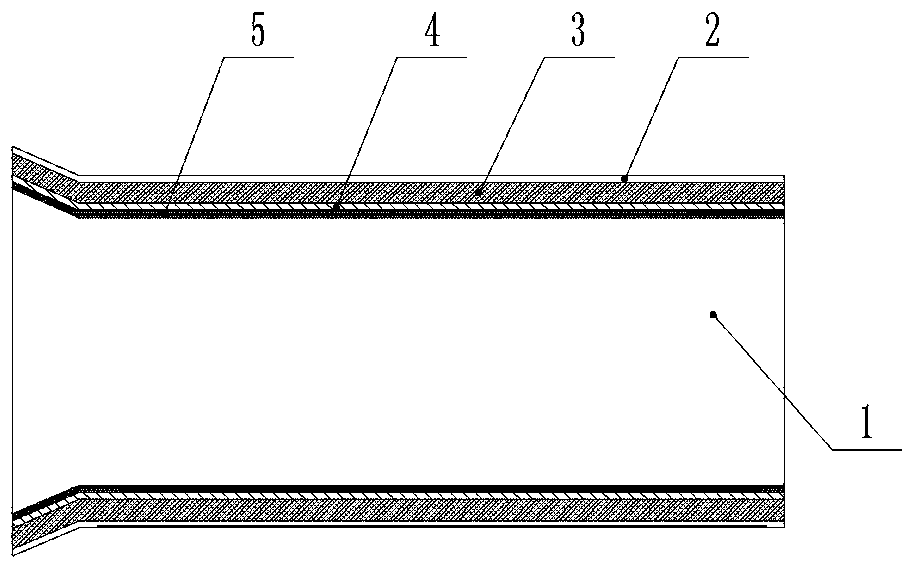

Image

Examples

Embodiment 1

[0029] A preparation method of a high-strength corrosion-resistant ductile cast pipe, comprising the following steps:

[0030] 1) Clean the inner surface of the ball mill cast pipe, clean and polish the inner wall of the pipe to ensure that the inner wall of the pipe is clean and smooth;

[0031] 2) Brush the adhesive layer on the inner surface of the clean ball mill cast pipe, the thickness of the adhesive layer is 0.2-0.4mm, and paint in 1-3 times.

[0032] 3) When the adhesive layer is semi-dry, spray the prepared cement mortar on the adhesive layer under uniform stirring to form a cement mortar lining. During the spraying process, the ball mill cast pipe is rotated at high speed to make the cement mortar fit tightly. , evenly distributed, reducing hollowing; the thickness of the cement mortar is 2-6mm, and the rotation speed of the ball-milled cast pipe is kept at 300-700r / min to ensure that the cast pipe rotates smoothly along the central axis without vibration during the...

Embodiment 2

[0043] The specification of the high-strength and corrosion-resistant ball mill cast pipe is DN100, and the preparation method includes the following steps:

[0044] 1) Clean the inner surface of the DN100 ball mill cast pipe, clean and polish the inner wall of the pipe to ensure that the inner wall of the pipe is clean and smooth;

[0045] 2) Configure the adhesive layer, weigh the following components by weight: 1 part of cement, 1.5 parts of water, 0.001 part of hydroxypropyl methylcellulose, 0.01 part of styrene-butadiene rubber powder, mix well, and spray onto a clean ball mill On the inner surface of the casting pipe, the spraying thickness of the adhesive layer is 0.2mm, and the spraying is carried out in 1-3 times.

[0046] 3) After spraying the adhesive layer, the prepared cement mortar is sprayed onto the adhesive layer while stirring evenly to form a cement mortar lining. During the spraying process, the ball mill cast pipe is rotated at high speed to make the cemen...

Embodiment 3

[0054] The specification of the high-strength and corrosion-resistant ball mill cast pipe is DN700, and the preparation method includes the following steps:

[0055] 1) Clean the inner surface of the ball mill cast pipe, clean and polish the inner wall of the pipe to ensure that the inner wall of the pipe is clean and smooth;

[0056] 2) Configure the adhesive layer and weigh the following components by weight: 1.5 parts of cement, 2 parts of water, 0.01 part of hydroxypropyl methylcellulose, and 0.005 parts of styrene-butadiene rubber powder. After mixing evenly, spray onto a clean ball mill On the inner surface of the casting pipe, the spraying thickness of the adhesive layer is 0.3mm, and the spraying is carried out in 1-3 times.

[0057] 3) After spraying the adhesive layer, the prepared cement mortar is sprayed onto the adhesive layer while stirring evenly to form a cement mortar lining. During the spraying process, the ball mill cast pipe is rotated at high speed to make...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com