Composite coating application, anti-corrosion material and preparing method of anti-corrosion material

A composite coating and anti-corrosion technology, applied in chemical materials and application fields, can solve problems such as rapid degradation obstacles, and achieve the effects of easy molding, high safety, and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

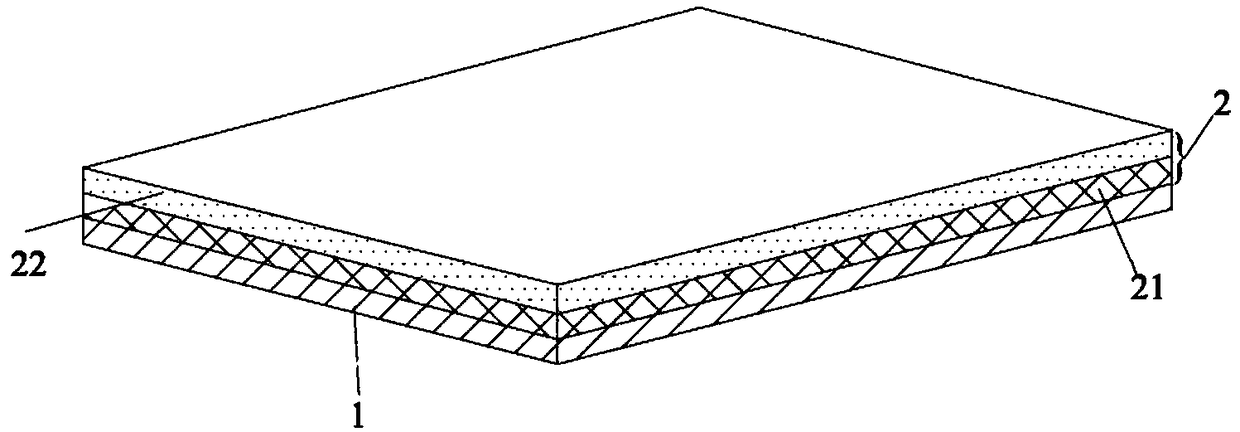

[0048] The first embodiment of the present invention provides an application of a composite coating in anti-corrosion. Such as figure 1 As shown, the composite coating 2 of the present invention may include: a hydrophilic layer 22 and a hydrophobic layer 21 in contact with each other,

[0049] The hydrophilic layer 22 contains hydrophilic substances, and the hydrophobic layer 21 contains hydrophobic substances.

[0050] The composite coating 2 of the present invention may be a Janus film, and a Janus film generally refers to a film structure with an asymmetric structure or property. The key to distinguish Janus membranes from general asymmetric membranes is whether the properties of the two sides of the membrane are "opposite", such as hydrophilic / hydrophobic or positively charged / negatively charged, etc. Called the Janus membrane. In the present invention, the composite coating 2 has two sides with different properties, that is, has a Janus structure, and can simultaneous...

no. 2 approach

[0063] The second embodiment of the present invention provides an anti-corrosion material. The anti-corrosion material includes: a substrate 1 and a composite coating 2 formed on the surface of the substrate 1;

[0064] The composite coating 2 is the composite coating 2 in the first embodiment.

[0065] Generally speaking, in the present invention, the composite coating 2 can be directly formed on the surface of the substrate 1, so as to play an anti-corrosion role. In the present invention, the composite coating 2 can also be pre-prepared, and then placed on the surface of the substrate 1, so as to play the role of anti-corrosion.

[0066] The composite coating 2 in the anti-corrosion material of the present invention prevents liquid penetration under the joint action of hydrophobic force, static pressure and capillary force, thereby achieving the purpose of anti-corrosion. The composite coating 2 will not allow liquid to penetrate, and the liquid will not enter the composit...

no. 3 approach

[0073] The third embodiment of the present invention provides a method for preparing an anti-corrosion material according to the second embodiment of the present invention, comprising:

[0074] Material acquisition step: dissolving a hydrophobic substance in a first solvent to obtain a hydrophobic material; dissolving a hydrophilic substance in a second solvent to obtain a hydrophilic material;

[0075] Forming step: making the hydrophilic material and the hydrophobic material alternately form a composite coating 2 on the surface of the substrate 1; preferably,

[0076] The surface and / or inside of the composite coating 2 may have multiple pore structures, and the average pore diameter of the pore structures is between 0.1-1000 nm.

[0077] In this embodiment, the first solvent is a solvent that can dissolve or partially dissolve hydrophobic substances, such as dichloromethane, chloroform, benzene, tetrahydrofuran, and the like. The second solvent is a solvent that can dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com