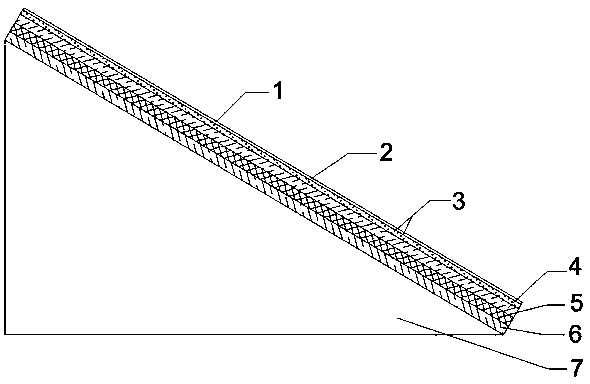

Ecological restoration method for engineering side slope treatment in alpine and high-altitude areas

A technology for engineering slope and ecological restoration, applied in infrastructure engineering, botanical equipment and methods, excavation, etc., can solve the problems of poor vegetation restoration effect, strong ultraviolet radiation, large temperature difference between day and night, etc., to improve the ecological restoration effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of matrix raw materials:

[0040] Construction soil: The surface soil excavated by the project is collected during construction, and it is further preferably air-dried, crushed, and passed through a 5mm sieve. The sand content in the soil is 5-10%, and the water content is 6-10%.

[0041] Peat soil: the organic matter content is more than 30%, the texture is soft and easy to break up, the specific gravity is 0.7-1.05, after air-drying, crushing, and passing through a 5mm sieve, the water content is 10-30%.

[0042] Coconut peat: Coconut shell fiber powder, air-dried, crushed, and passed through a 5mm sieve, with a water content of 10-30%.

[0043] High molecular polymer: Potassium polyacrylate-polyacrylamide copolymer, the absorption rate of 0.9% saline solution is 50-100%, the particle size is 0.2-0.5mm, and the service life is more than 5 years.

[0044] Vermiculite: The bulk density is about 0.2 g / cm³, the water absorption is 3 times, and the particl...

Embodiment 2

[0068] (1) The preparation of matrix raw materials is the same as in Example 1.

[0069] (2) Preparation and spraying of substrate layer for slope improvement

[0070] Raw materials are counted in parts by mass: 20 parts of organic waste compost, 20 parts of urban domestic sludge, 30 parts of natural mineral slag, and others are the same as in Example 1; mixed, stirred evenly, and sprayed on the exposed slope surface by a sprayer , the thickness is 3cm.

[0071] (3) Preparation and spraying of root-promoting and moisture-retaining matrix layer

[0072] Raw materials are counted in parts by mass: 30 parts of organic waste compost, 10 parts of mineral fertilizer, 5 parts of peat soil, and others are the same as in Example 1; mixed, stirred evenly, sprayed on the surface of the slope improvement substrate layer by a sprayer, and the thickness 3cm, and the spraying time of the root-promoting and moisture-conserving matrix layer and the slope-improving matrix layer are 12 hours a...

Embodiment 3

[0080] (1) The preparation of matrix raw materials is the same as in Example 1.

[0081] (2) Preparation and spraying of substrate layer for slope improvement

[0082] Raw materials are counted in parts by mass: 25 parts of organic waste compost, 30 parts of urban domestic sludge, 15 parts of natural mineral slag, and others are the same as in Example 1; mixed, stirred evenly, and sprayed on the surface of the exposed slope by a sprayer , the thickness is 4cm.

[0083] (3) Preparation and spraying of root-promoting and moisture-retaining matrix layer

[0084] Raw materials are counted in parts by mass: 25 parts of organic waste compost, 5 parts of mineral fertilizer, 15 parts of peat soil, and others are the same as in Example 1; mixed, stirred evenly, sprayed on the surface of the slope improvement matrix layer by a sprayer, and the thickness 4cm, and the spraying time of the root-promoting and moisture-containing matrix layer and the slope-improving matrix layer are 12 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com