A liquid-cooled photovoltaic cell junction box and a working method thereof

A photovoltaic cell and junction box technology, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of low thermal conductivity, heat can not be conducted in time, and high working temperature of diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The purpose of the present invention can be achieved through the following technical solutions:

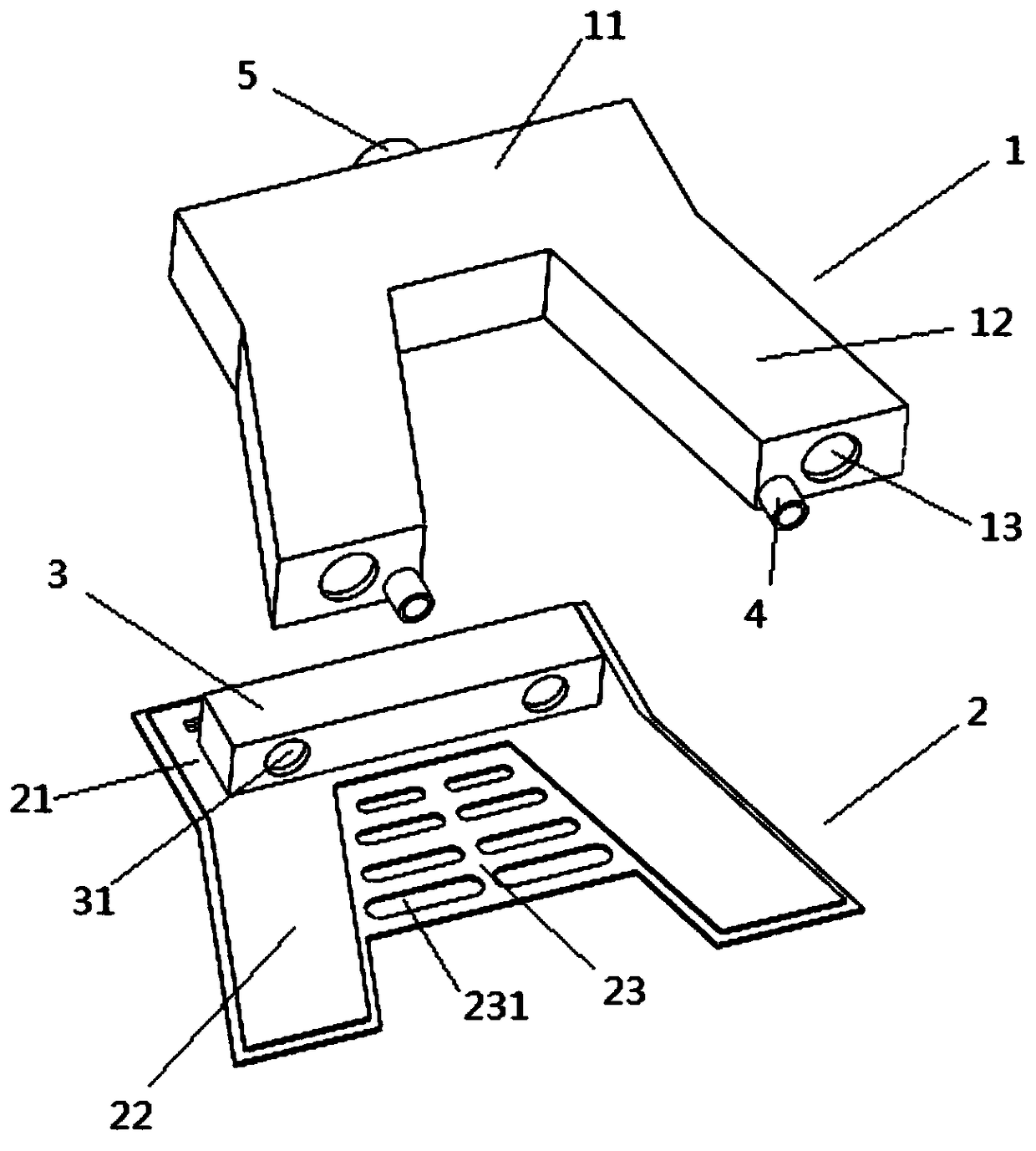

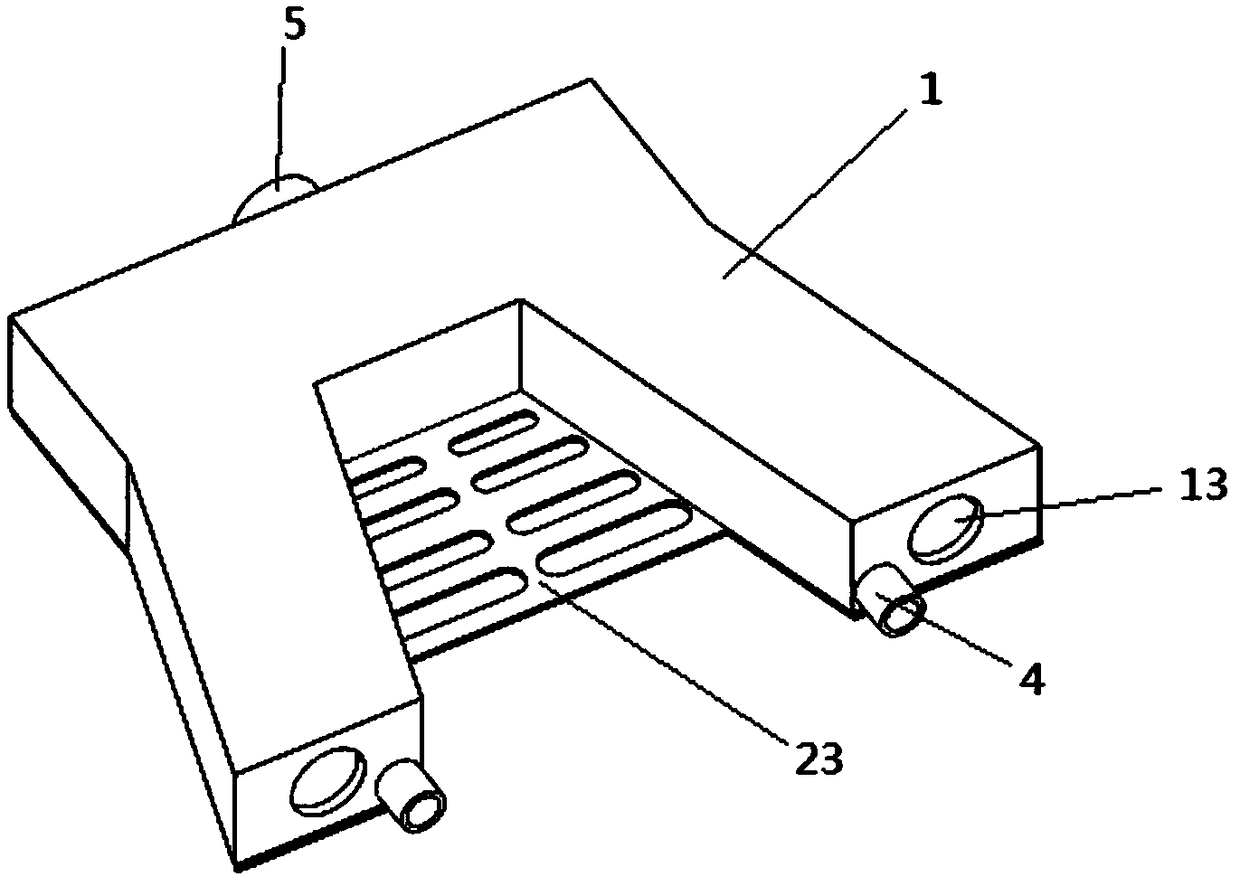

[0029] A liquid-cooled photovoltaic cell junction box, see Figure 1-3 , including upper cover 1, back plate 2, wiring box 3, liquid inlet pipe 4, and liquid outlet pipe 5;

[0030] An upper cover 1 is installed on the back plate 2, and a wiring box 3 is arranged on the back plate 2 between the upper cover 1 and the back plate 2; the upper and lower sides of the upper cover 1 are respectively provided with a liquid inlet pipe 4 and a liquid outlet pipe 5 , the liquid inlet pipe 4 and the liquid outlet pipe 5 are through holes on the upper cover 1, and the liquid inlet pipe 4 and the liquid outlet pipe 5 respectively penetrate through the two side walls of the upper cover 1;

[0031] The upper cover 1 includes a wiring cover 11, a wire cover 12, and a wire opening 13. A wire cover 12 is arranged below the wiring cover 11. Two wire cover 12 are located at two ends of the wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com