An intelligent management system for construction of a roller compacted concrete dam

A technology of roller compacted concrete and construction intelligence, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of fatigue driving of material transport drivers, managers cannot grasp information anytime and anywhere, and cannot be supervised, etc. Achieve the effect of improving management efficiency and reducing project risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

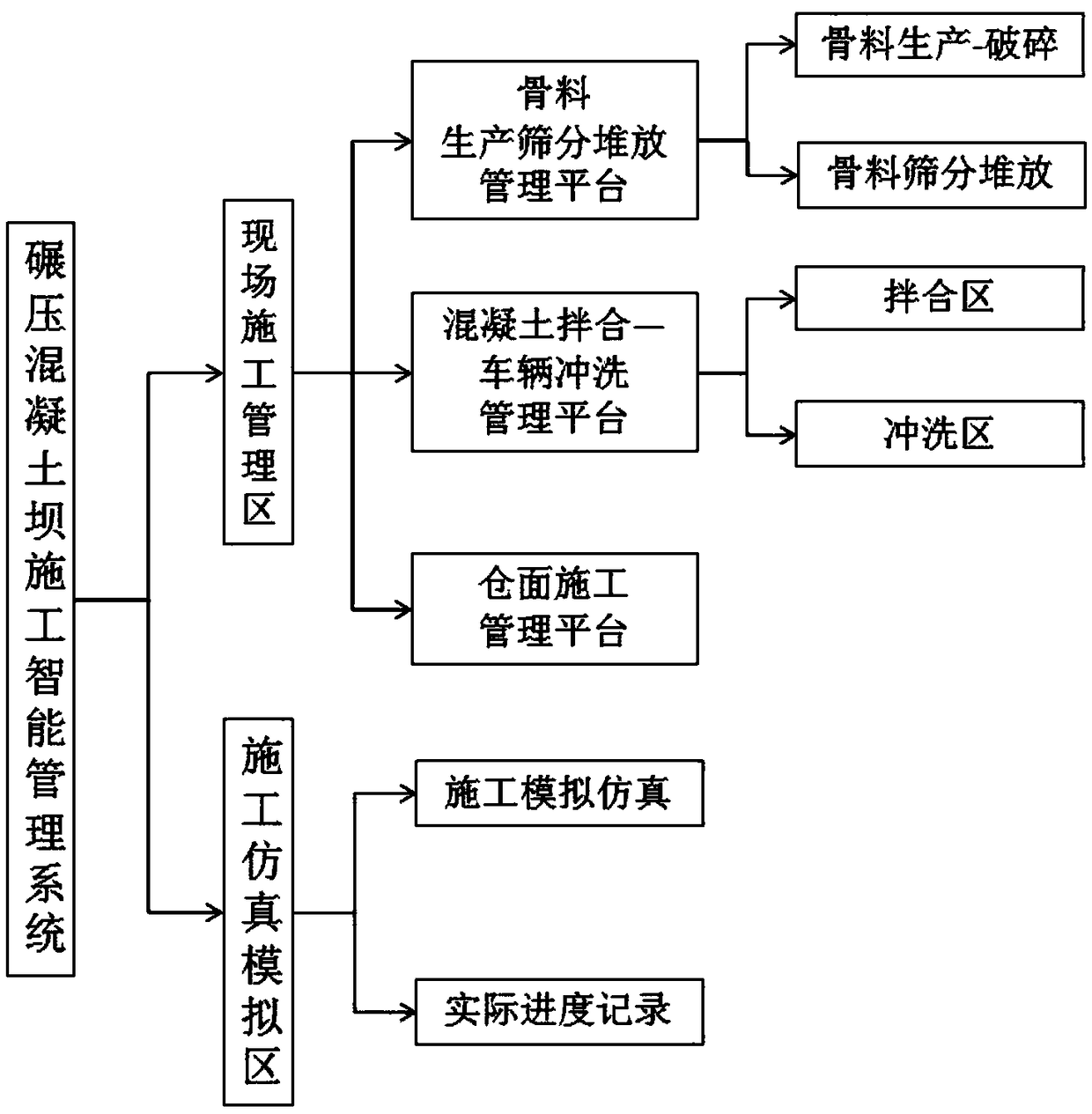

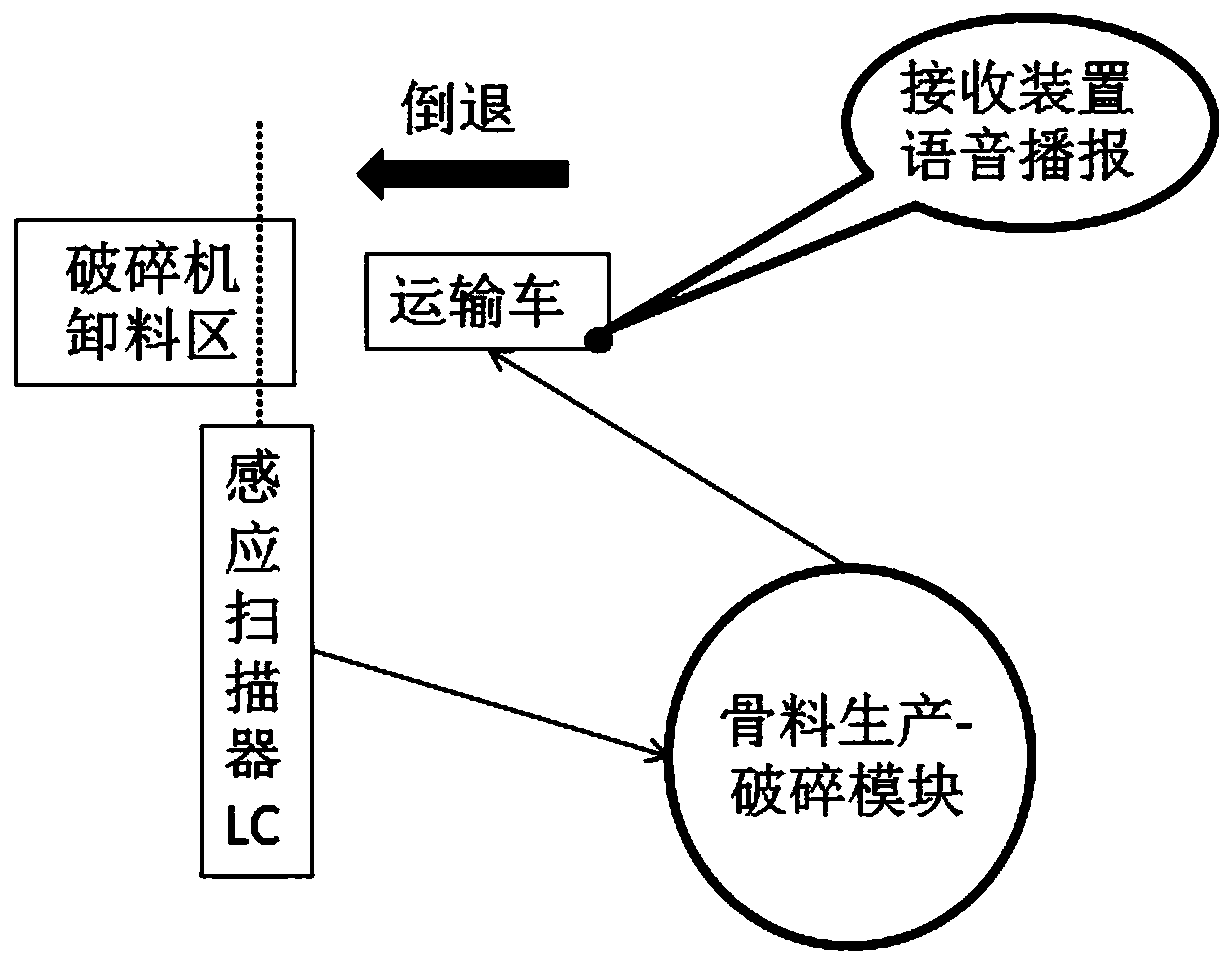

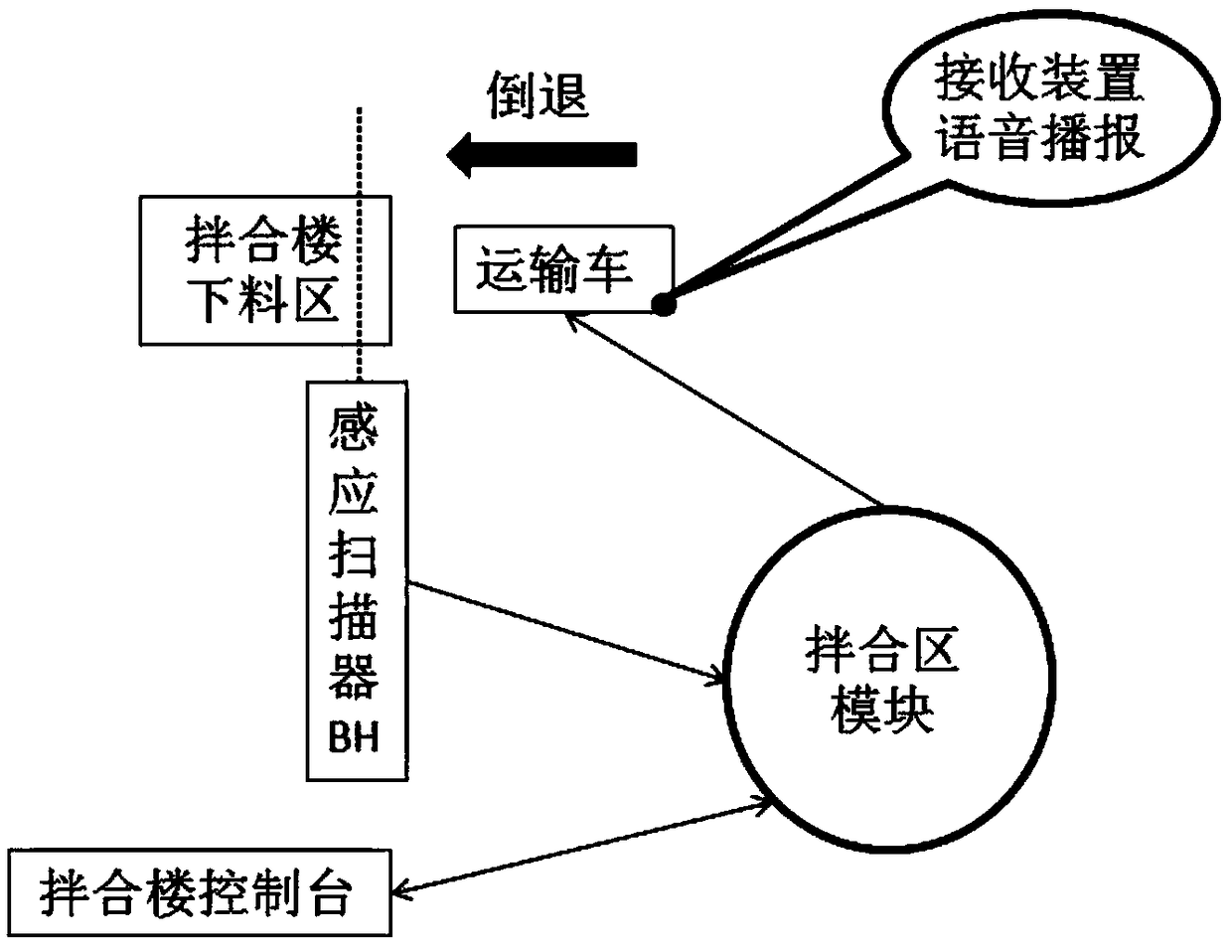

[0031] see Figure 1-Figure 7 Summary of the invention: a kind of roller compacted concrete dam construction intelligent management system of the present invention, comprises on-the-spot construction management area, construction emulation simulation area. The on-site construction management area includes the aggregate production, screening and stacking management platform, the concrete mixing-vehicle washing management platform, and the storage surface construction management platform; the construction simulation simulation area includes the construction simulation simulation module and the actual progress recording module. Further, the aggregate production, screening and stacking management platform includes an aggregate production-crushing module, and an aggregate screening and stacking module. Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com