A Power Cycle Loading Method Including Periodic Intervals

A power cycle and periodic technology, applied in the direction of applying repeated force/pulsation force to test the strength of materials, can solve the problems of low economy and large safety factor, and achieve the effects of enhanced guidance, reduced damage, and reduced deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

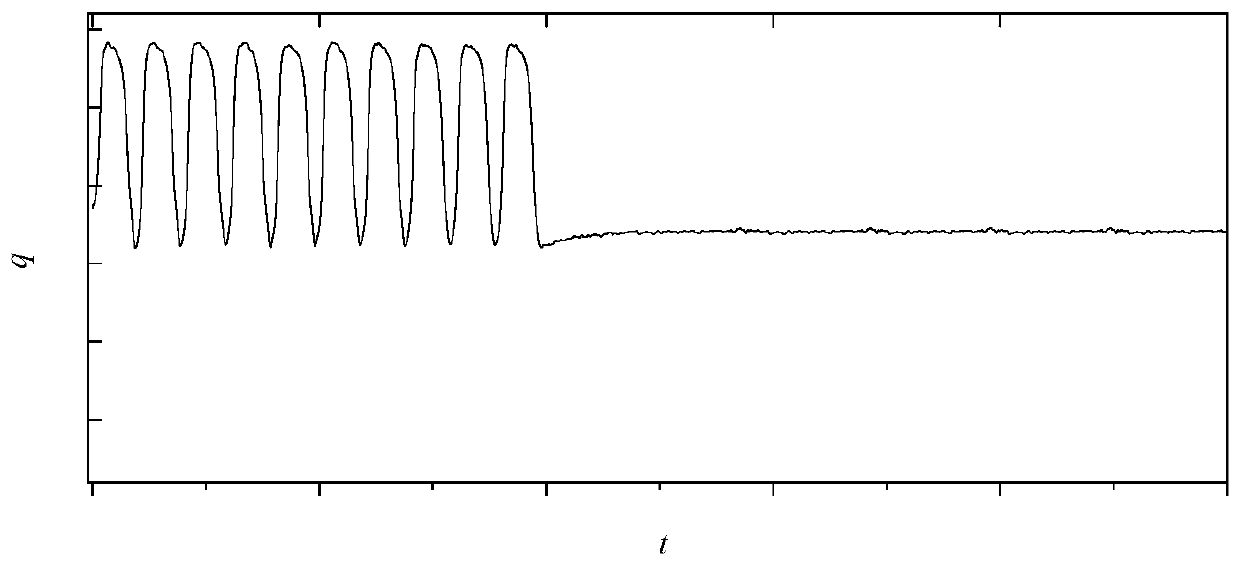

[0053] In this embodiment, a dynamic triaxial test is performed based on a GDS dynamic triaxial instrument. The power cycle loading method including periodic intervals is described in detail below, and the steps are as follows:

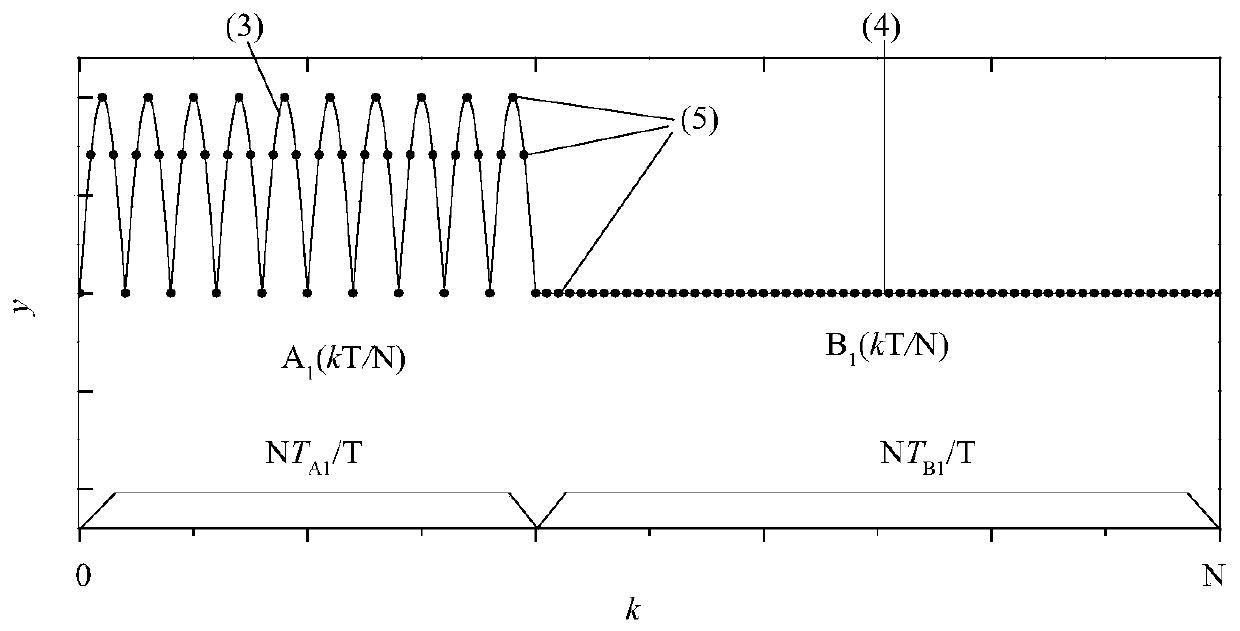

[0054] 1) Determine the data accuracy of the custom vibration curve supported by the triaxial instrument. Under this accuracy, the number of data points that the instrument can support is N. There are 1000 fixed on the GDS moving triaxial, that is, N=1000. And the distribution of data points on the abscissa axis in the instrument must be evenly spaced.

[0055] 2) Determine the unit cycle time T of the target load;

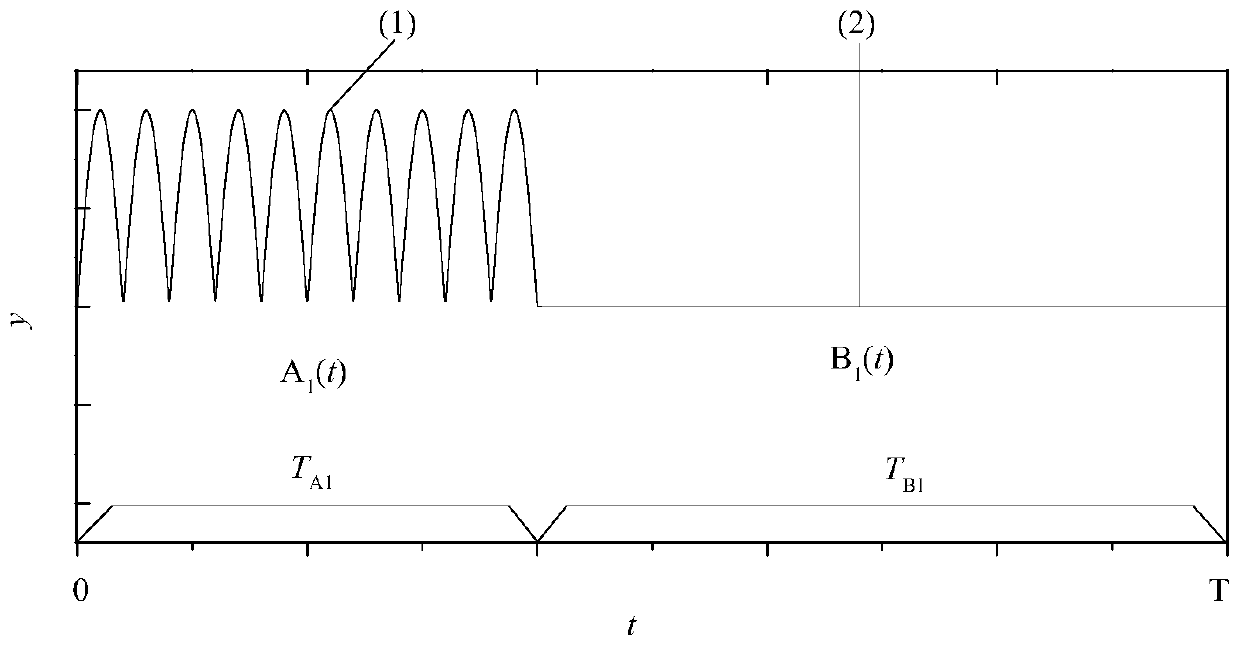

[0056] 3) Determine the cyclic form of the target load, that is, the function curve F(t) of each cycle of the target vibration curve. In the function curve of this embodiment, there is one significant function and one insignificant function respectively, so F(t) is a function about time t, and the expression is as follows:

[0057] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com