Water soft yoke mooring model test system

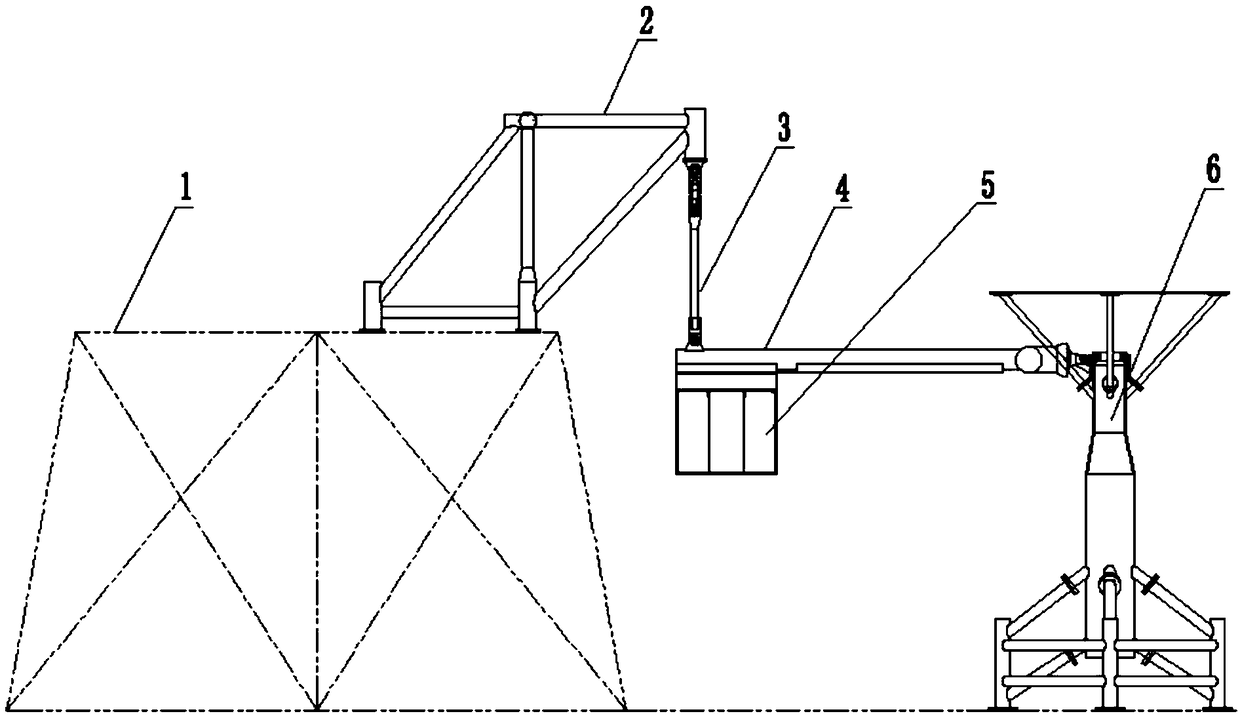

A model test, soft rigid arm technology, applied in the mooring field, can solve problems such as restricting research progress, inability to obtain response data, design safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0027] Implementation case (damage identification of the internal thrust joint bearing at the upper end of the mooring leg)

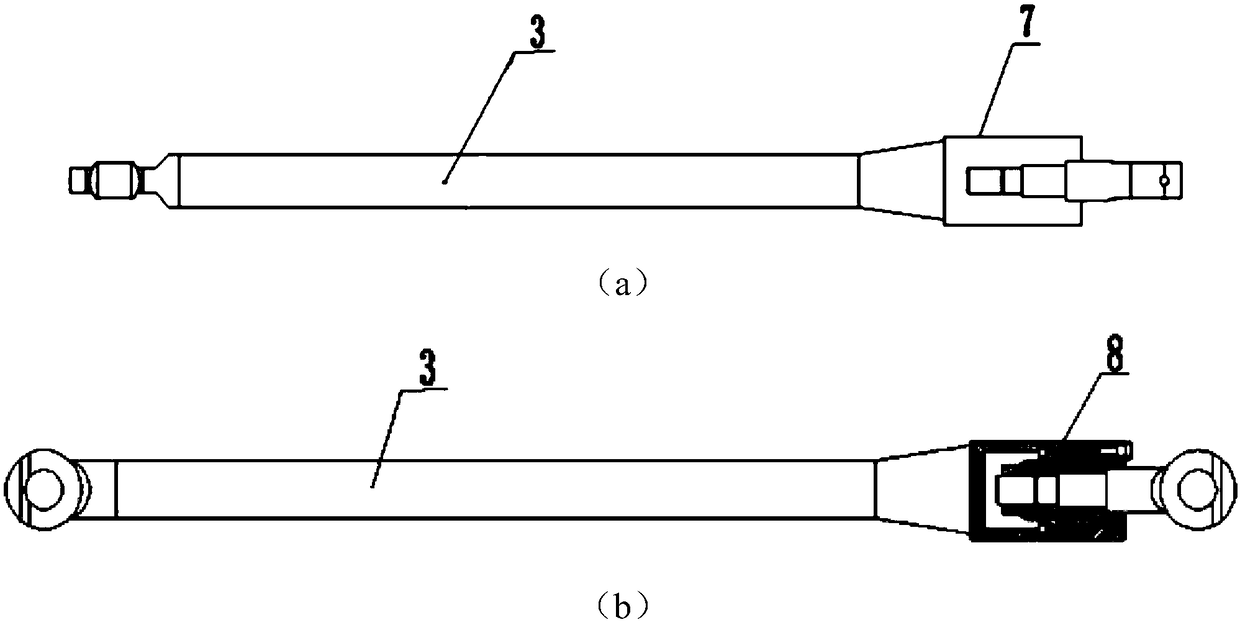

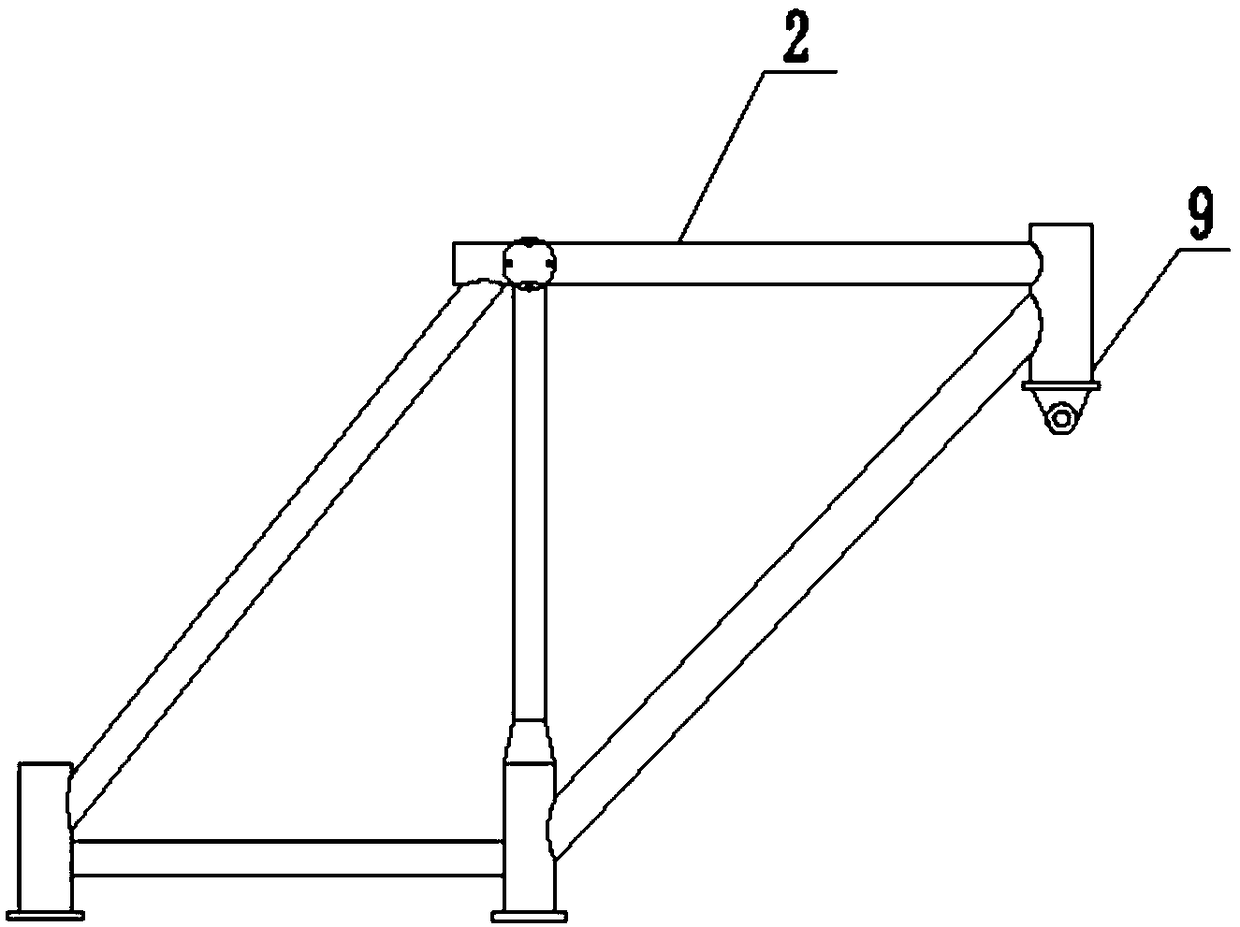

[0028] like figure 2 As shown in , this test model is used to carry out the damage identification test of the internal thrust joint bearing at the upper end of the mooring leg. First, replace the thrust joint bearing inside the upper end of the left mooring leg with a notch (artificially manufactured), and keep the right one unchanged; then arrange a single-axis acceleration sensor at position 7, which represents two mutually perpendicular directions, facing The internal thrust joint bearing and the single-axis acceleration sensor are fixed at position 7 with good glue; at the same time, the camera is fixed at position 9 with a steel hoop (two cameras on the left and right), connect the hard disk video recorder, open the video software on the computer, and turn on the power Adjust the camera to align the position of the connecting rod at the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com