LED light-emitting board without dark side

A technology of light-emitting panels and LED strips, applied in light guides of lighting systems, semiconductor devices of light-emitting elements, optics, etc., can solve the problems of being unable to be illuminated, unsatisfied, and unable to be used normally, so as to increase the difficulty of transportation and transport Effects of cost, increased installation space, and increased packaging volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

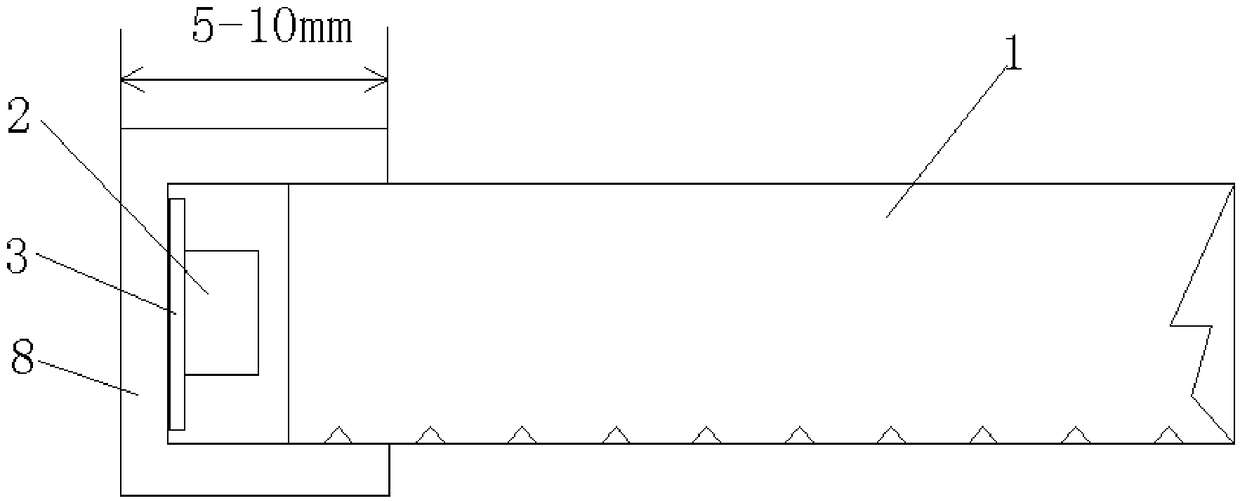

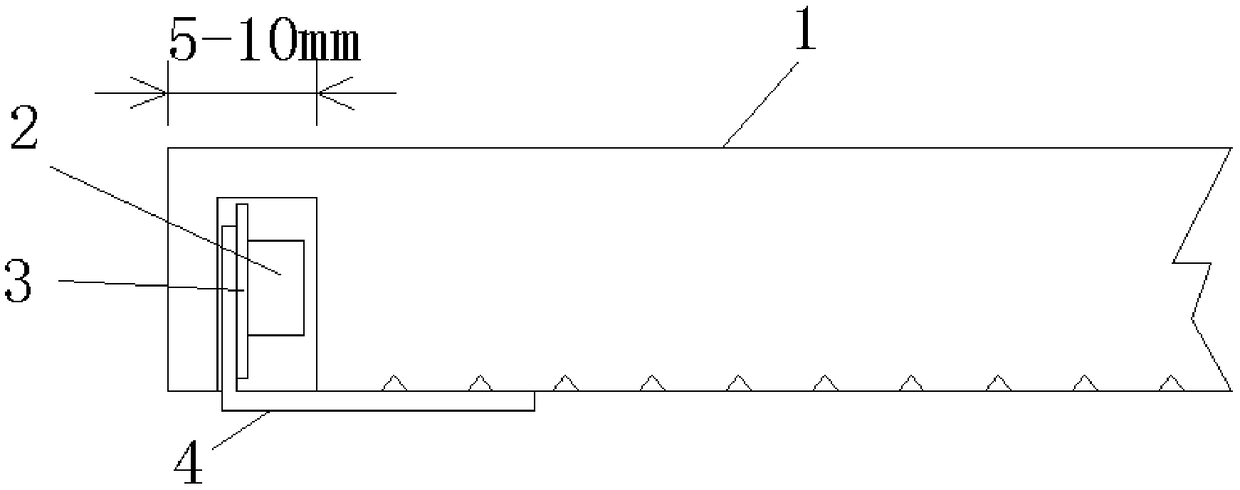

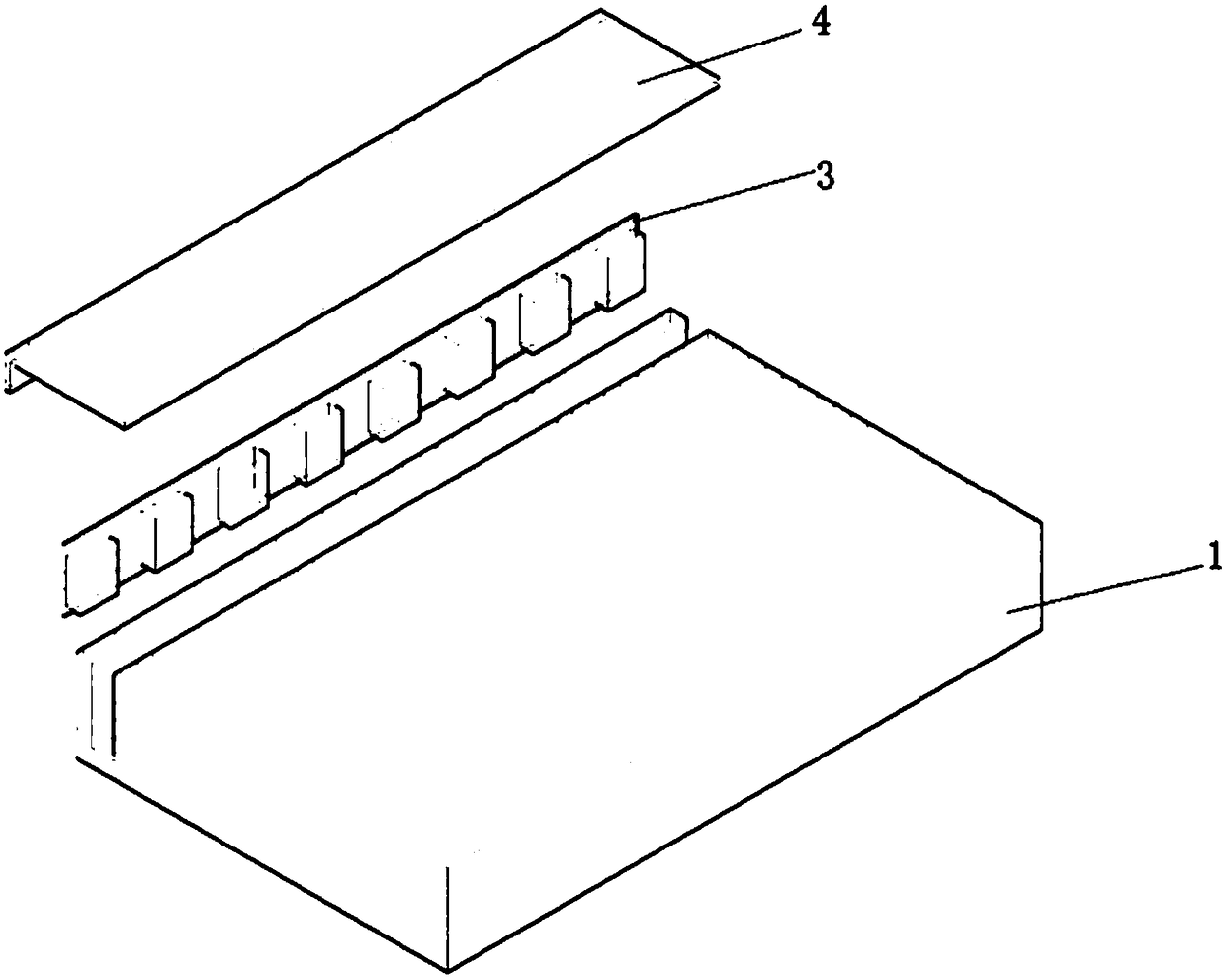

[0033] refer to Figure 5 As shown in -7, the present invention provides an LED luminous panel without dark edges, which includes a luminous panel body 1 and an LED light bar 3. A notch is provided on one side of the luminous panel body 1, and the notch is located on the backlight surface. , the light-emitting surface forms a boss 5, an LED light strip is installed at the gap of the light-emitting board body 1, LED light beads 2 are installed on the LED light strip 3, an L-shaped aluminum connection plate is installed on the side of the boss 5, and an L-shaped aluminum connecting plate is installed. The connecting plate 4 is fixed to the side of the boss 5 through heat-conducting double-sided adhesive tape, and the back of the L-shaped aluminum connecting plate 4 is fixed to the backlight surface of the luminous panel body 1 .

[0034] Preferably, the LED light bar 3 is pasted on the L-shaped aluminum connecting plate 4 with a heat-conducting adhesive tape.

[0035] The L-sha...

Embodiment 2

[0043] refer to Figure 8 As shown, the power cord installation groove is set on the back of the luminous panel body, the power cord can go out from any position on the back or side of the luminous panel body, the processing size of the power cord installation groove can be processed to the size of the power cord, and then Put in transparent AB glue or transparent hot melt glue, after the power cord is completely solidified in the power cord installation groove, fix the power cord with rivets at the outlet to increase the firmness.

[0044] The light-emitting board body of the present invention can be a rectangular, square, circular or other special-shaped light-emitting board. The back of the light-emitting board body is CNC processed according to the thickness of the LED light bar, and the processing depth is CNC processed according to the width of the LED light bar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com