Multi-stage yielding contracting type steel frame based on constant-resistance sliding hole shearing losses and connection method thereof

A sliding hole and steel frame technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems that the construction effect of retractable steel frame is difficult to guarantee, the timing of transition cannot be effectively controlled, and the sliding resistance is unstable. Achieve the effect of not increasing the construction process, easy to promote, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

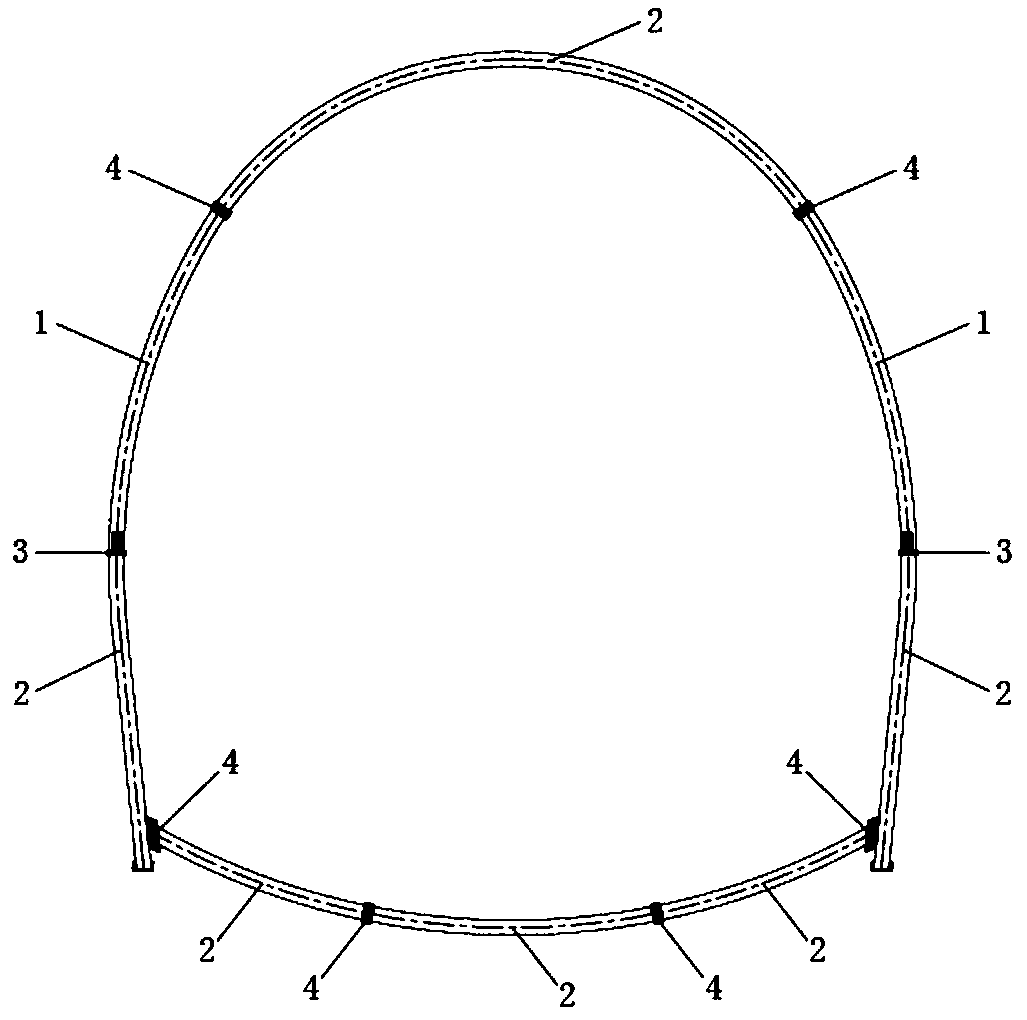

[0035] Such as figure 1 Shown is a schematic arrangement of a multi-stage yielding compressible steel frame joint based on constant resistance sliding hole shear loss, including a shrinkable steel frame unit 1, a common steel frame unit 2, a shrinkable joint 3, and a common joint 4. Generally, two shrinkable joints are arranged for each steel frame, symmetrically arranged according to the center line of the tunnel section. Common joint 4 is the traditional steel frame joint that adopts steel plate, angle steel and bolt connection.

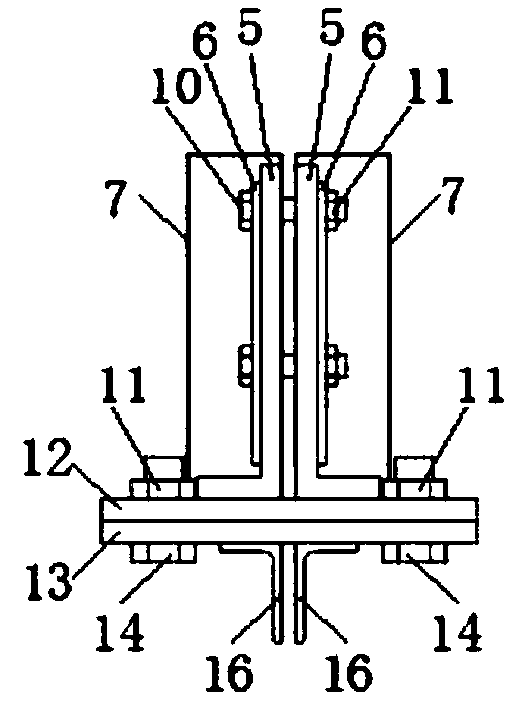

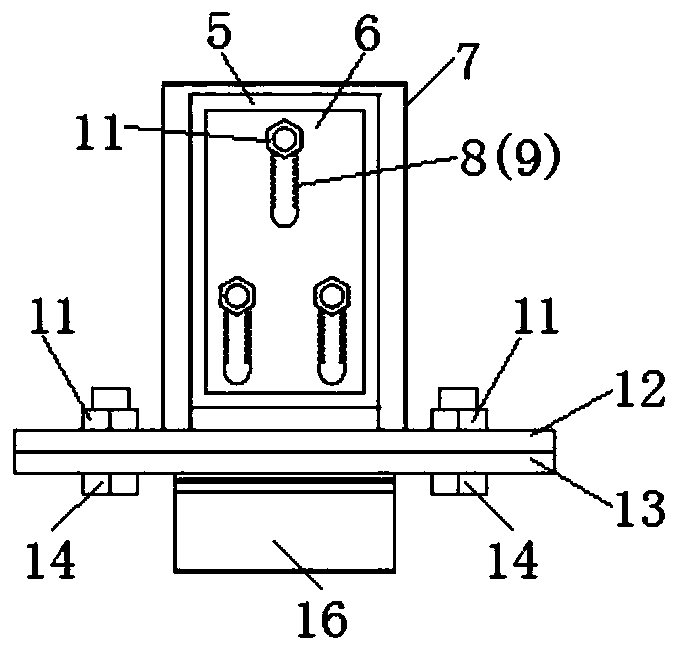

[0036] Such as Figure 2-5 As shown, the shrinkable joint 3 is composed of an L-shaped support 5, a constant resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com