Oil storage depot, oil storage method and construction method in closed pit mine main road

A technology for oil storage and oil depots, which is applied in the direction of large-capacity bulk material storage, buildings, building types, etc., can solve the problems of difficult construction of underground oil storage, difficult storage capacity adjustment, storage body damage, etc., so as to improve the development utilization rate, Avoid polluting the environment and reduce the effect of air content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

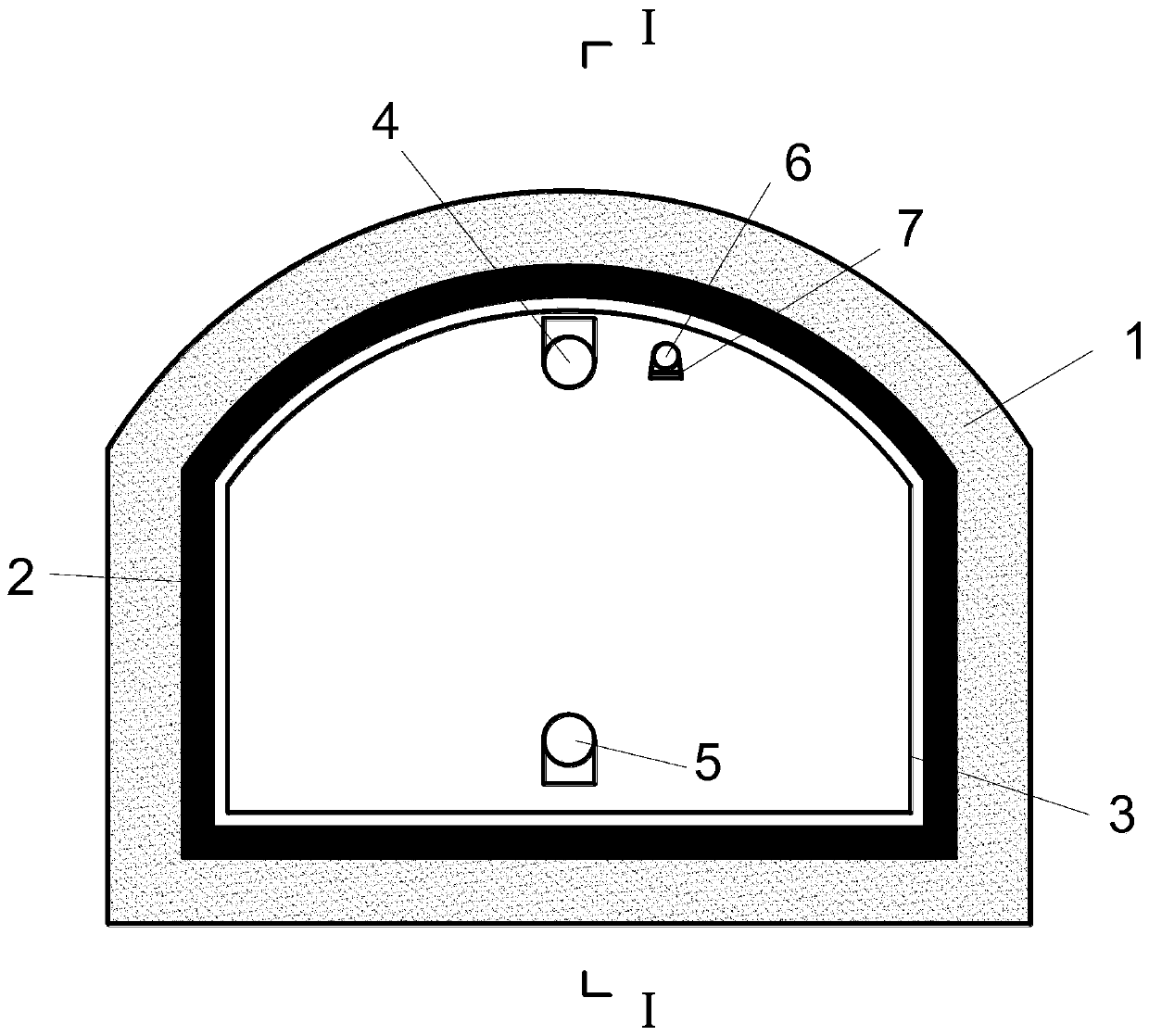

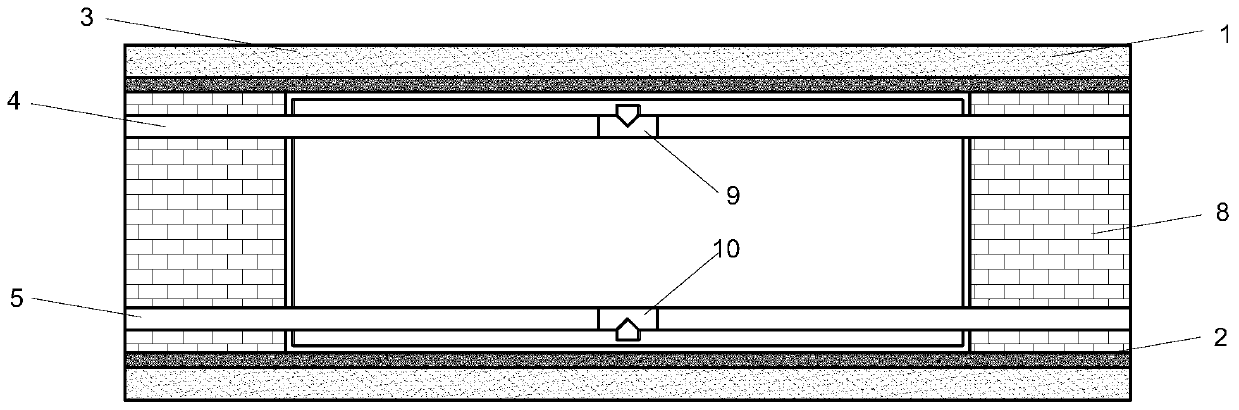

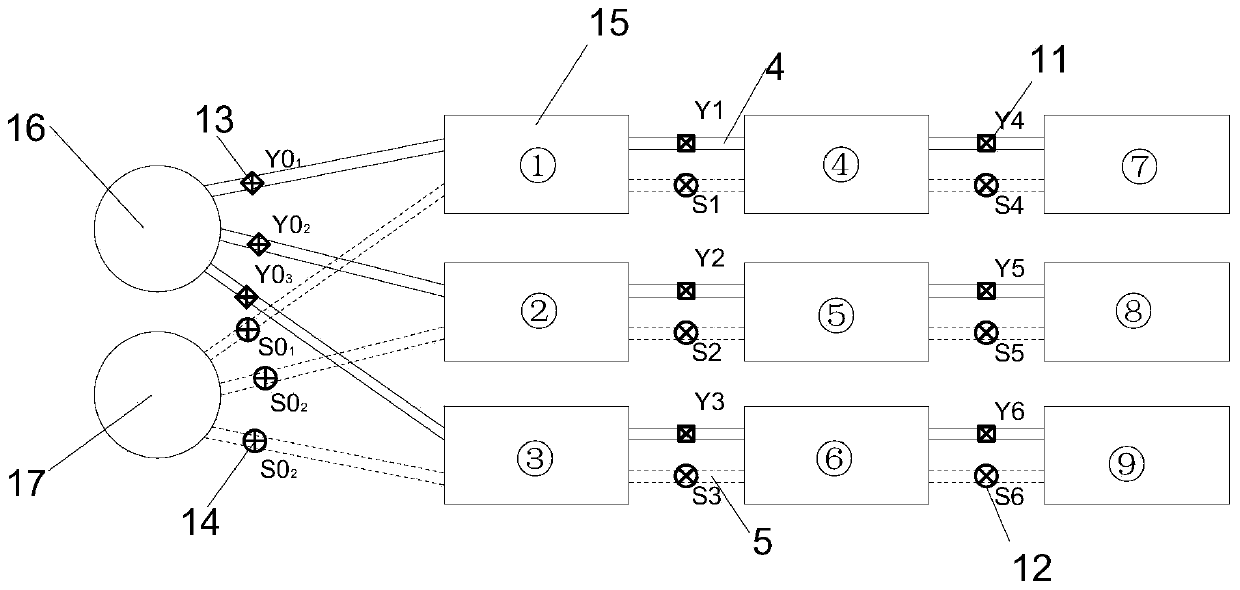

[0040] A specific embodiment of the present invention, such as Figure 1 to Figure 2 As shown, an oil storage depot in a closed mine shaft is disclosed, which includes a storage body and an artificial dam body 8, the storage body is built in a closed pit mine shaft, and the artificial dam body 8 is used to block the storage body; Including the overall structure composed of roadway surrounding rock 1, concrete sprayed layer 2 and steel plate layer 3; oil injection and production pipeline 4 and pressure regulating pipeline 6 are arranged on the top of the reservoir body, pumping water injection pipeline 5 is arranged at the bottom of the reservoir body; oil injection and production pipeline 4 is provided with The electric control valve 9 of the oil production pipeline in the single storage, the water injection pipeline 5 in the single storage is provided with the electric control valve 10 of the water injection pipeline in the single storage, the electric control valve 9 of the o...

Embodiment 2

[0055] A specific embodiment of the present invention discloses an oil storage method for an oil storage depot in a closed mine shaft, including three stages of water injection in an empty depot, oil injection and drainage, and oil production and water injection; stage cycle;

[0056] In the water injection stage of the empty storage, use the water pump to fill the empty oil storage with water;

[0057] In the oil injection and drainage stage, the oil injection pipeline and the water suction pipeline are opened, the oil outlet pipeline and the water injection pipeline are closed, and while the water pump pumps out the water in the oil depot, the oil pump is turned on to inject oil into the oil depot;

[0058] In the stage of oil production and water injection, the oil production pipeline and water injection pipeline are opened, and the oil injection pipeline and water outlet pipeline are closed. While the oil pump pumps out the oil in the oil depot, the water pump is turned on...

Embodiment 3

[0066] A method for constructing an oil storage depot in a closed mine shaft, comprising the following steps:

[0067] Step 1: Screening of alternative roadways; Screen suitable closed pit mines as alternative roadways according to ground conditions and geological conditions. The oil storage depot is built underground, and the underground is a constant temperature environment, which is not affected by temperature and climate conditions, and is fireproof, explosion-proof, and lightning-proof.

[0068] 1. Ground conditions.

[0069] The basic ground conditions for suitable mines to build underground oil storage depots by using closed mine shafts and roadways are: (1) close to ports and pipelines, which is convenient for crude oil transportation; (2) sufficient water sources to meet the water demand of oil storage methods; (3) The reservoir construction block should avoid villages, towns, farmland, and rivers to prevent oil spill pollution.

[0070] 2. Geological conditions.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com