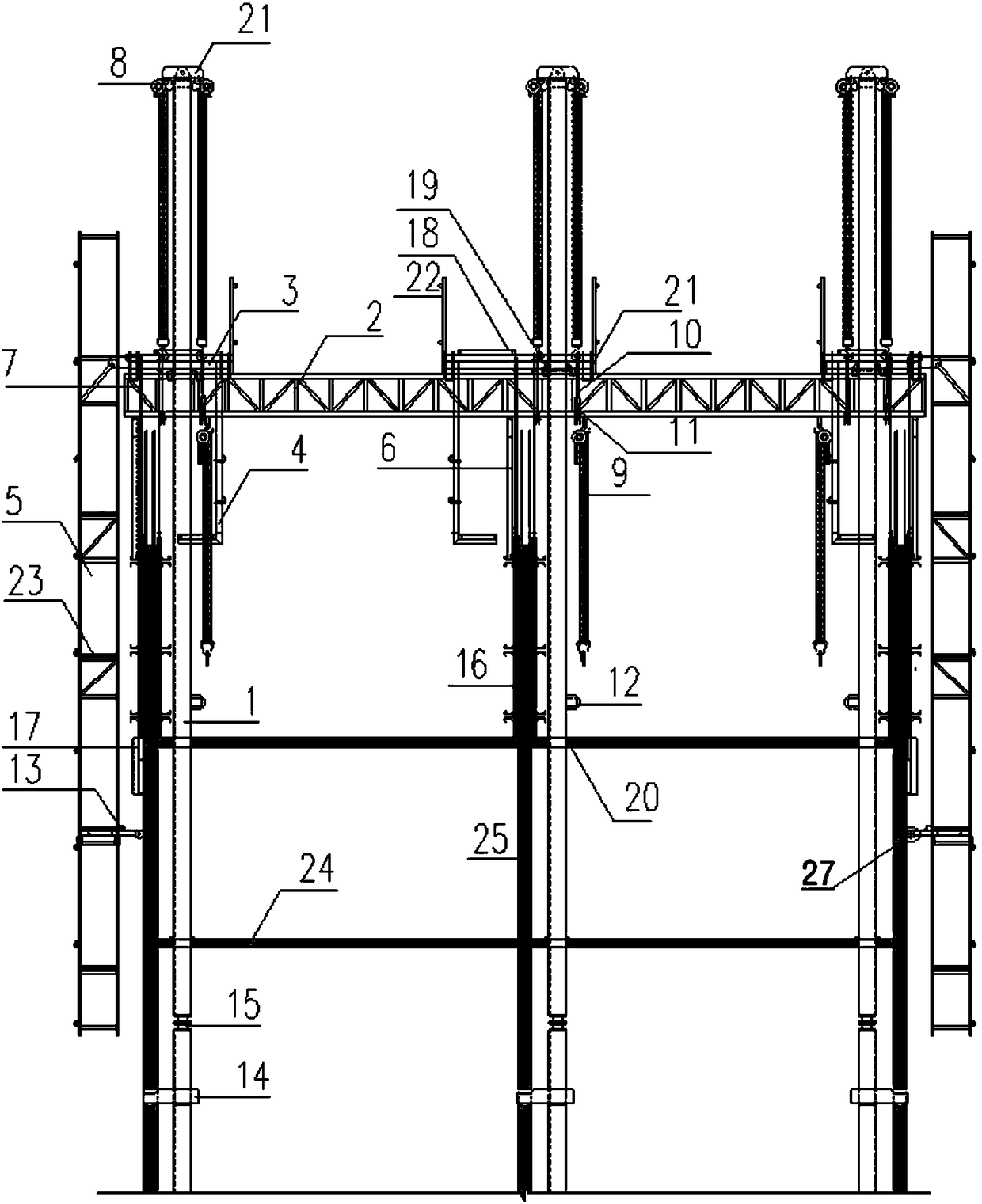

High-rise building construction steel formwork and operation frame integral lifting platform device

A platform device and overall lifting technology, which is applied in the direction of formwork/formwork/work frame, building, building structure, etc., can solve the problems of increasing workload and labor intensity, shorten the construction period, reduce labor costs, and speed up installation fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

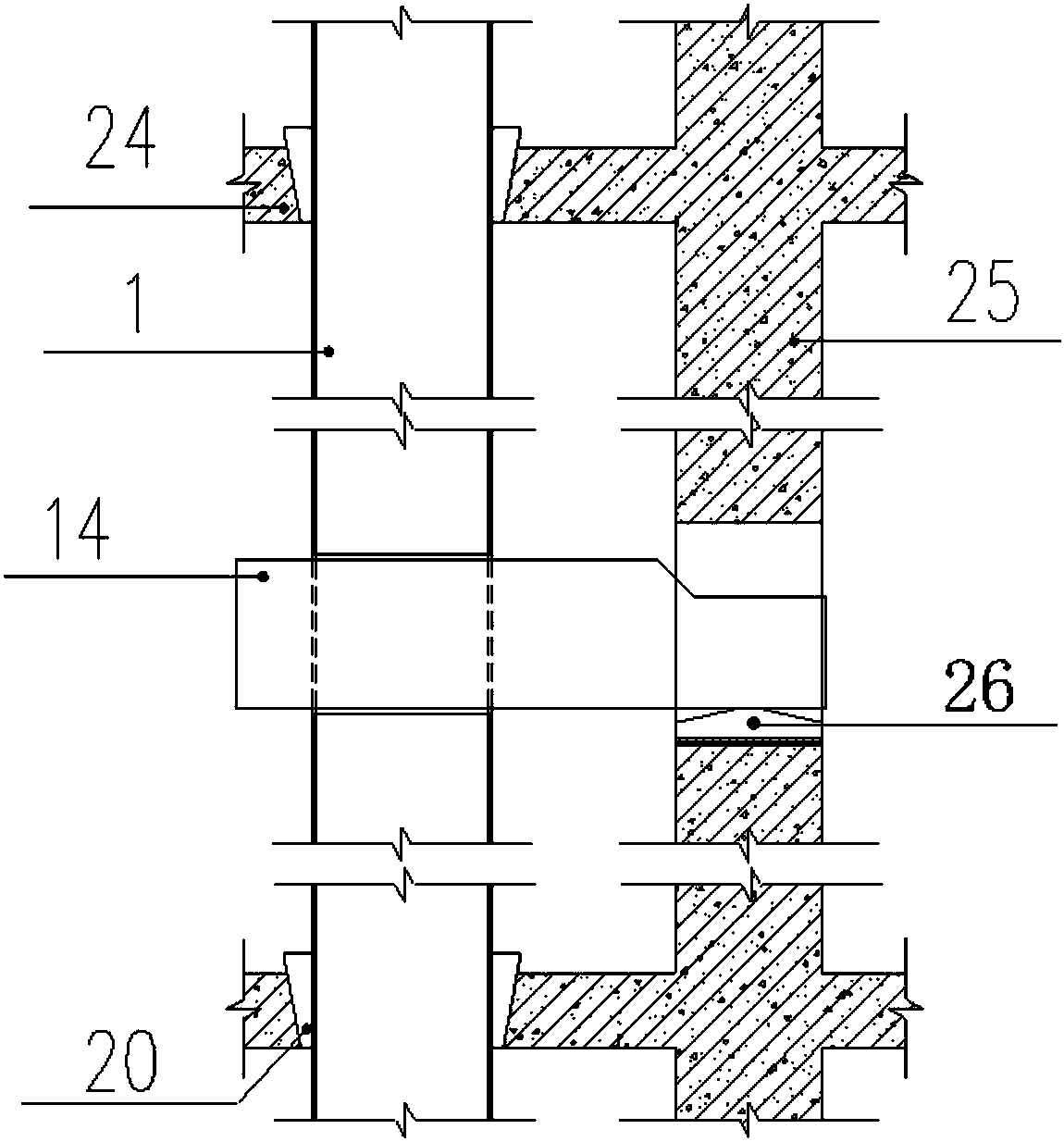

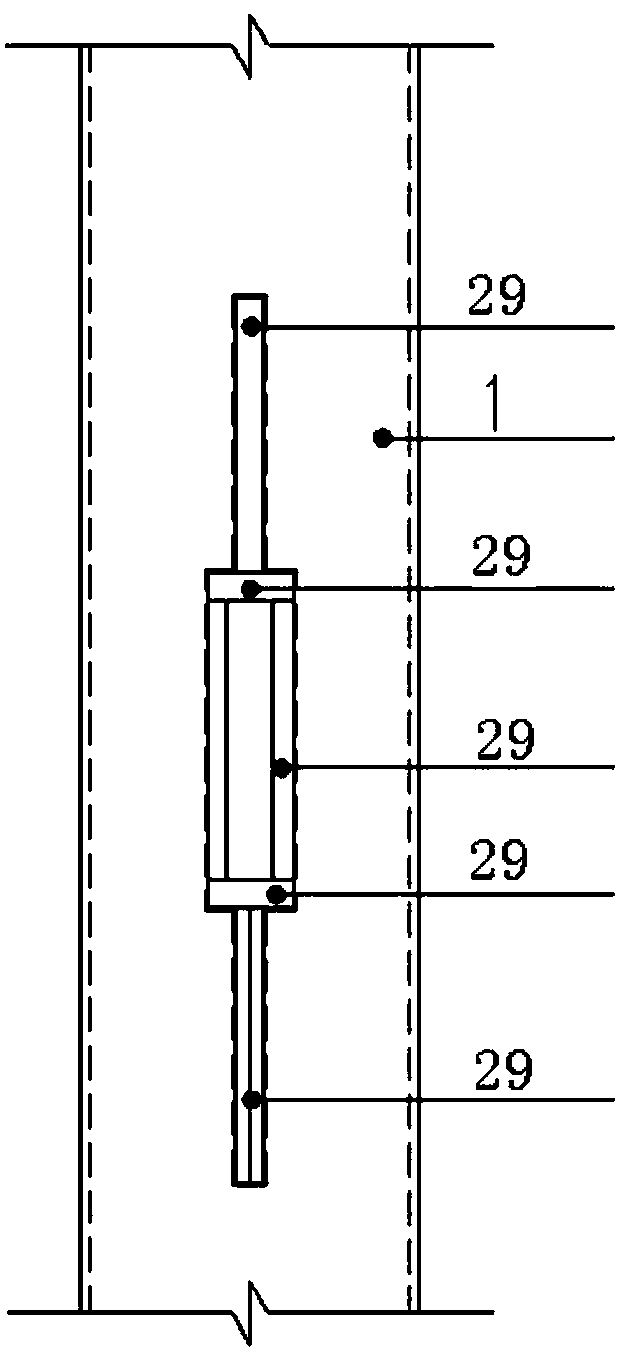

[0048] In order to illustrate the structure of the present invention, Figure 1 to Figure 18 Different examples were carried out, specifically, figure 1 It exemplarily shows a schematic diagram of the overall structure of the present invention; figure 2 A schematic diagram of the connection between the support column and the wall is shown as an example; image 3 A schematic diagram of a pin hole in a support column is shown as an example; Figure 4 A schematic diagram of the structure of the rigid opening on the support column is shown as an example (corresponding to figure 2 top view); Figure 5 An exemplary diagram showing the connection between the top of the support column and the upper electric hoist; Image 6 A schematic diagram of the elevation structure of the top of the support column is shown as an example; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com