Steel grating through-type drifting clamping feeding mechanism

A floating clamping and feeding mechanism technology, applied in metal processing, attachments of sawing machines, metal sawing equipment, etc., can solve the problems of wasting time, poor process continuity, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

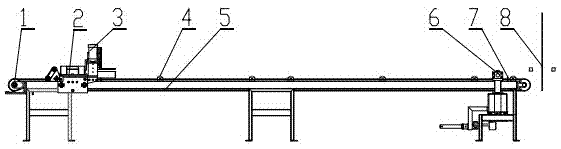

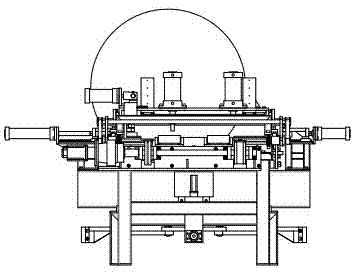

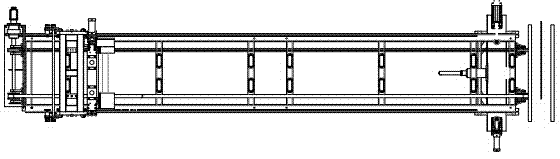

[0005] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a steel grating passing floating clamping feeding mechanism, characterized in that the servo transmission mechanism 1 drives the feeding trolley 2 to move forward and backward along the feeding platform 5, the conveying roller table 4 is arranged on the feeding platform 5, and the clamping on the feeding trolley 2 The steel grating mechanism 3 is a horizontal U-shaped clamp on both sides. The position of the lower clamping plate of the U-shaped clamp is lower than the upper cut surface of the conveying roller table 4, so that the conveyed steel grating can pass through the U-shaped clamp, and the power controls the U-shaped clamp. Clamping and fixing up and down; the clamping steel grating mechanism 3 on the feeding trolley 2 is a horizontal U-shaped fixture on both sides, and the U-shaped fixture on one side can move along the A slide rail 18 under the drive of the A cylinder 19, so that It clamps h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com