System and method for extracting industrial lithium carbonate by supergravity

A super-gravity, lithium carbonate technology, applied in alkali metal carbonates, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of complex process, unfavorable large-scale industrial preparation, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

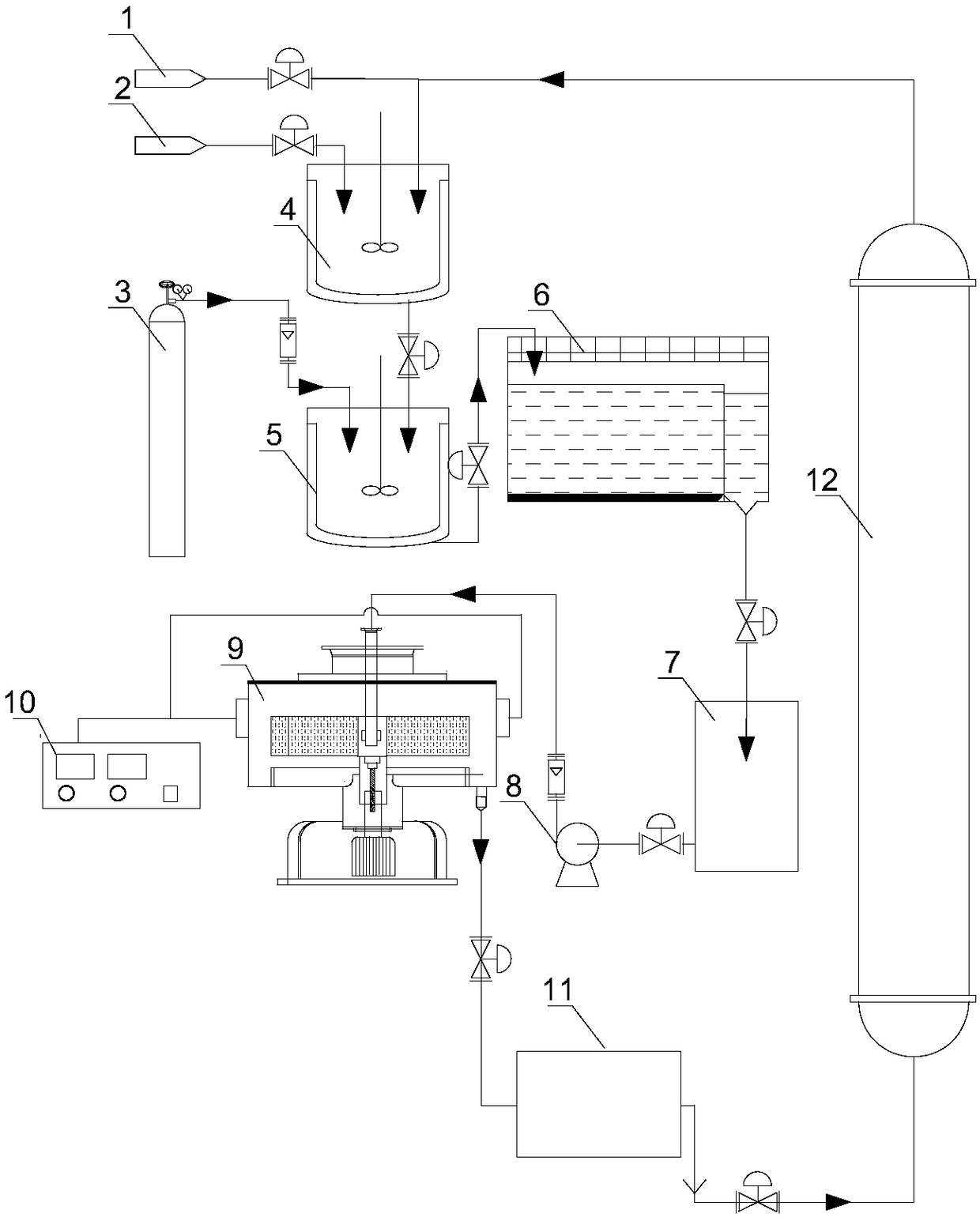

[0037] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0038] At present, battery-grade or high-purity lithium carbonate lacks industrialized large-scale preparation technology. Most preparation technologies require ion exchange process, but ion exchange is expensive, complicated process, and slow exchange rate, which is not conducive to large-scale industrial preparation.

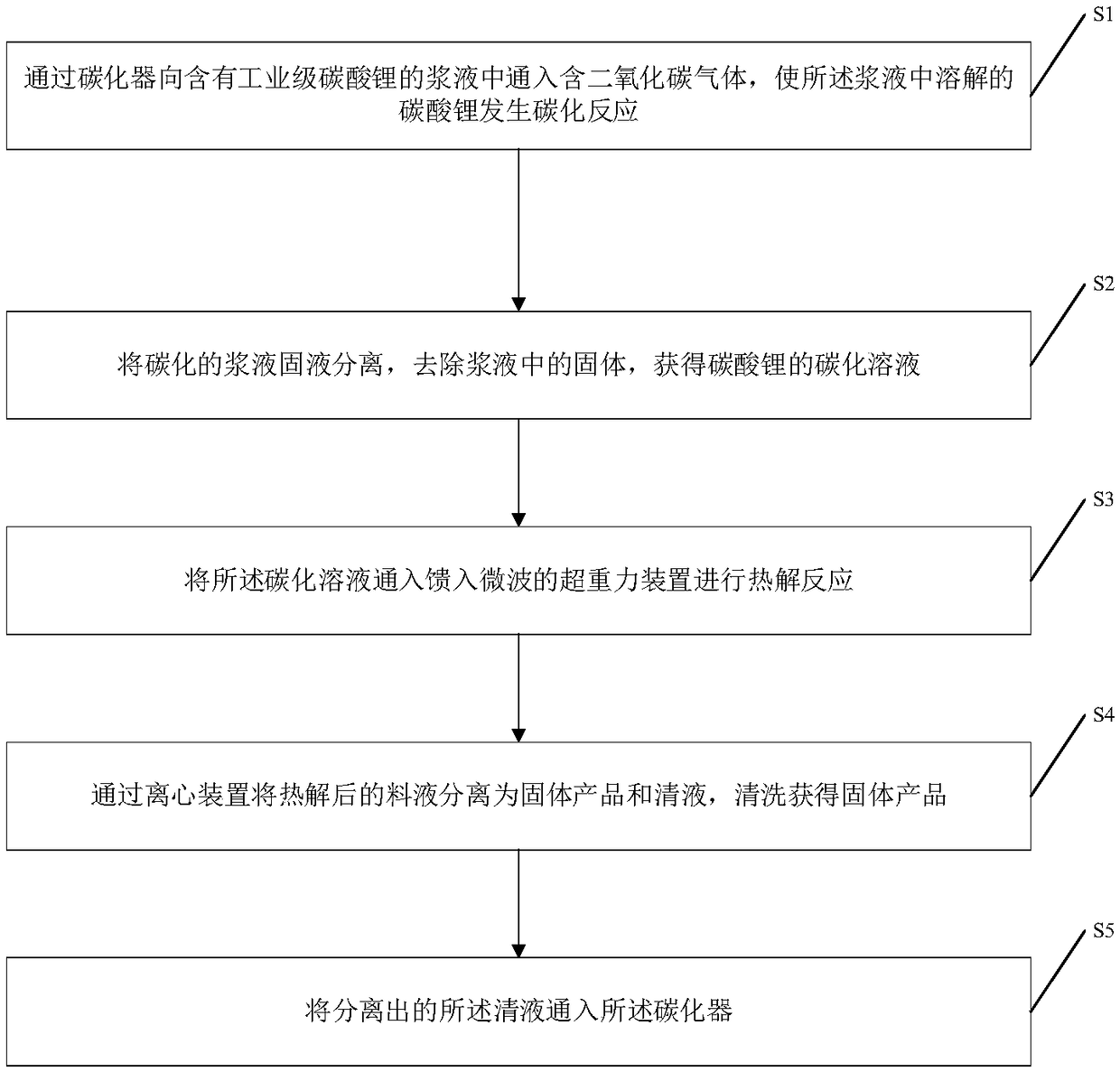

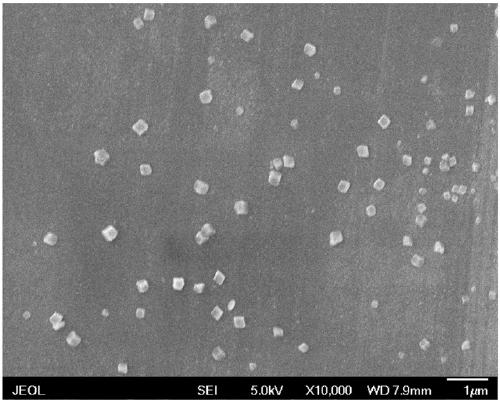

[0039] Therefore, in order to be able to purify and prepare battery-grade or high-purity lithium carbonate from industrial-grade lithium carbonate without using an ion-exchange process, and the production r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com