Combined tool used for assembling air quality sensor

A technology of air quality and sensors, applied in the direction of assembly machines, metal processing, manufacturing tools, etc., can solve problems such as errors, and achieve the effects of improving efficiency, improving combination accuracy, and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

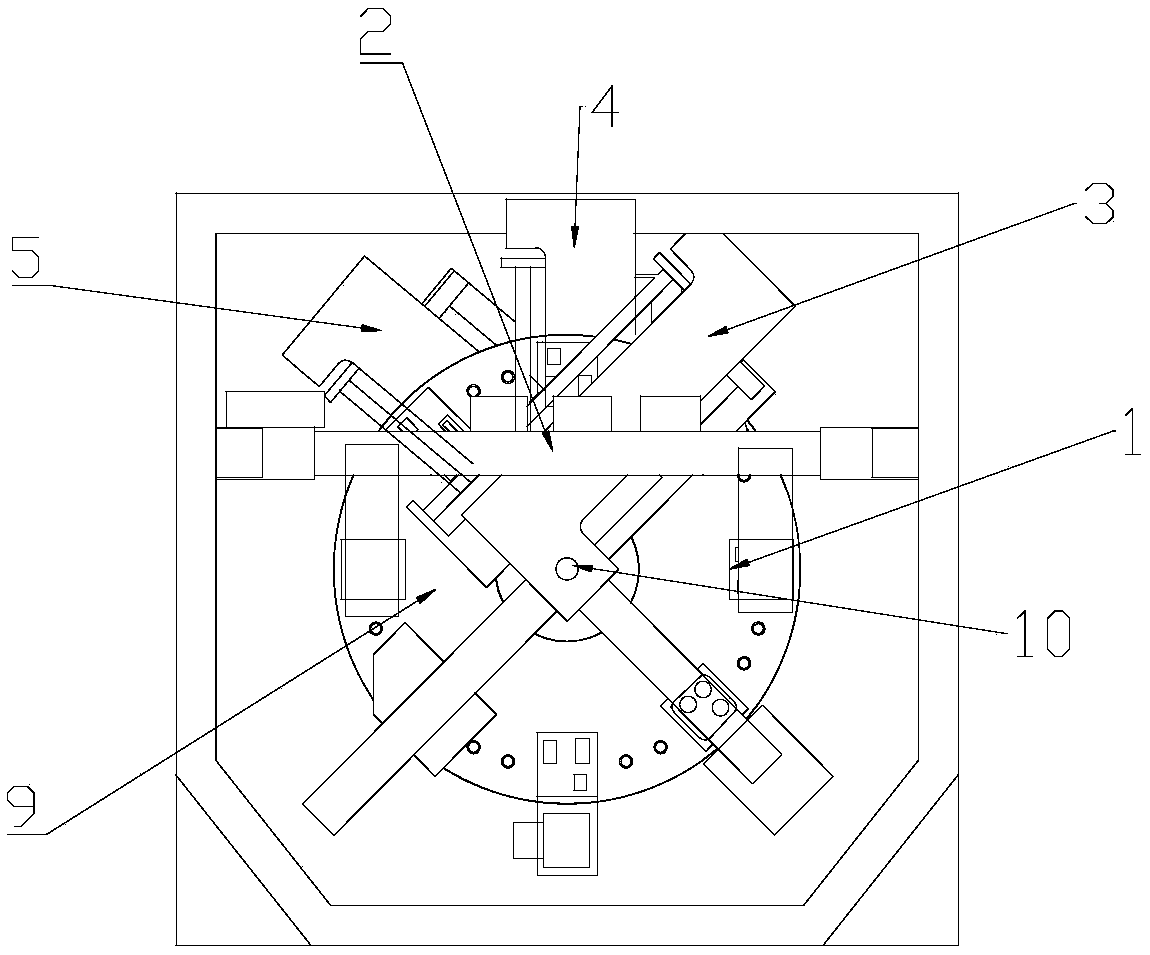

[0022] Such as figure 1 As shown, a combination tool for assembling an air quality sensor, the air quality sensor is assembled from a PCBA board, a film casing and a connector casing, and the combination tool includes a workbench 1, a pneumatic source 2, a correction Part 3, PCBA board feeding part 4 and film shell feeding part 5, said workbench 1 is provided with PCBA board fixing groove 11, film casing fixing groove 12 and connector shell fixing groove 13, and said PCBA board Placed in the fixing groove 11 of the PCBA board, the film shell is placed in the fixing groove 12 of the film shell, and the connector shell is placed in the fixing groove 13 of the connector shell.

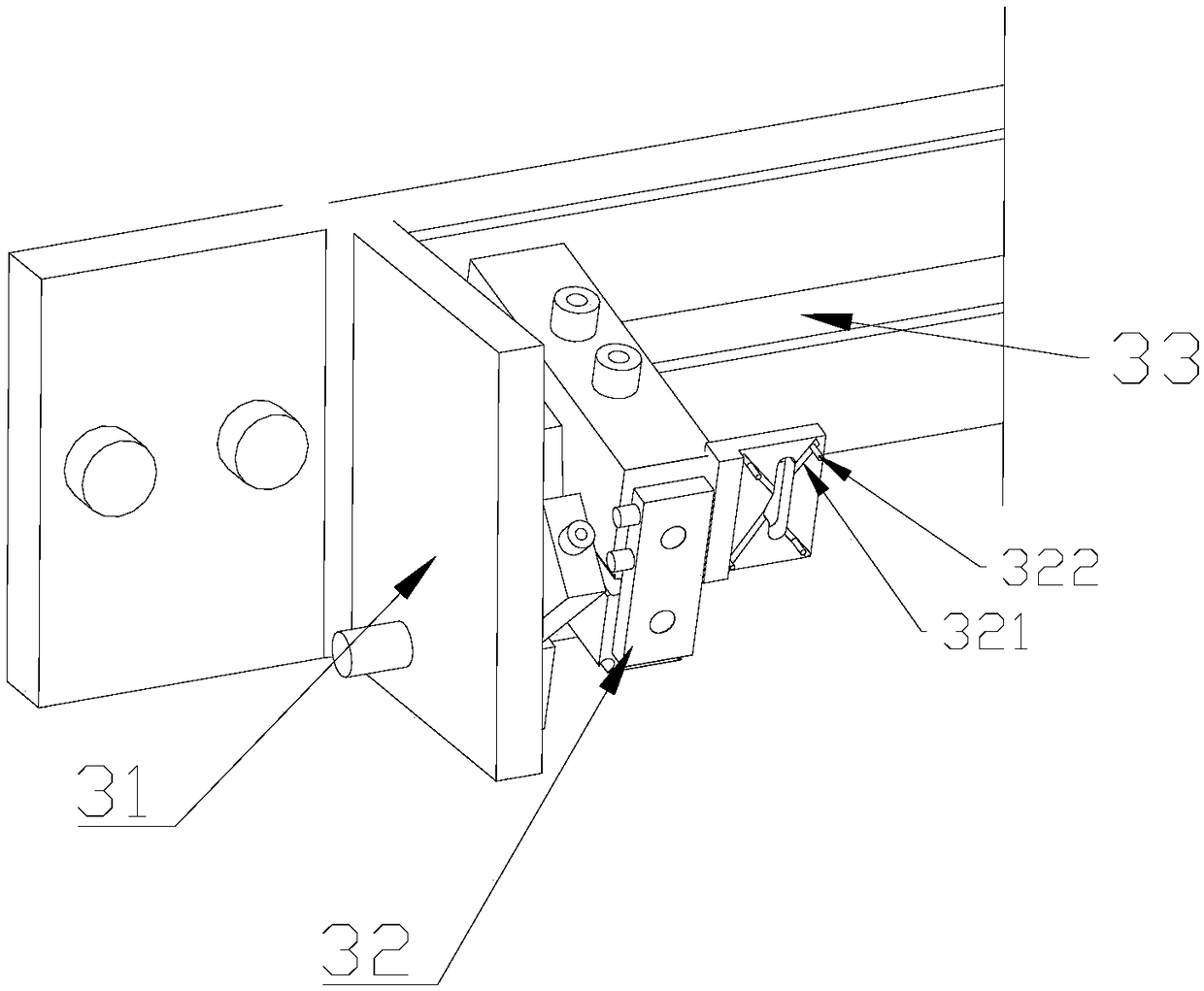

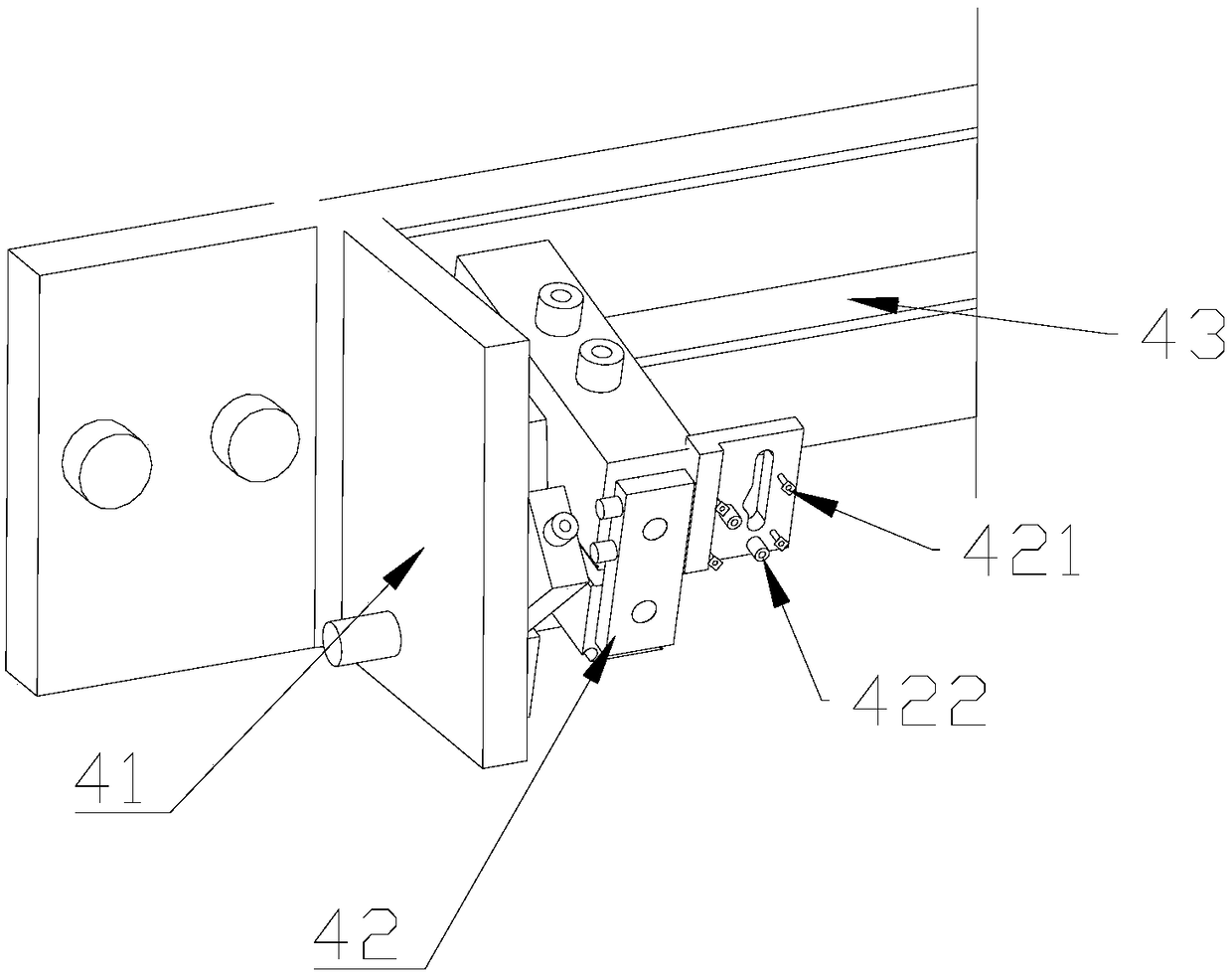

[0023] Described correcting part 3, PCBA board feeding part 4 and film shell feeding part 5 comprise respectively the support arm a 31, support arm b41, support arm c 51 fixed on the main shaft 10, support arm a 31, support arm b 41. The ends of the supporting arm c 51 are respectively connected to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com