Automatic feeding double arc stamping machine

An automatic feeding, double arc machine technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of manpower and material resources, manual feeding, etc., to reduce labor costs, and to adjust conveniently, accurately and quickly. , the effect of reducing the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

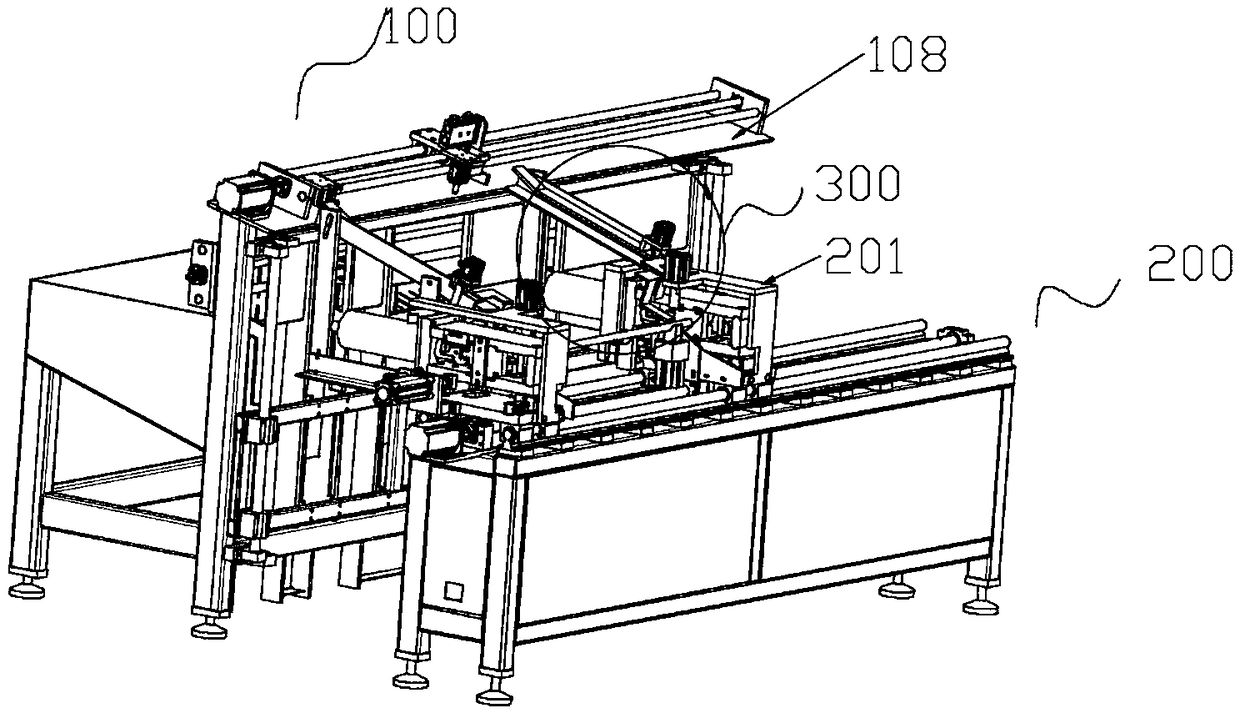

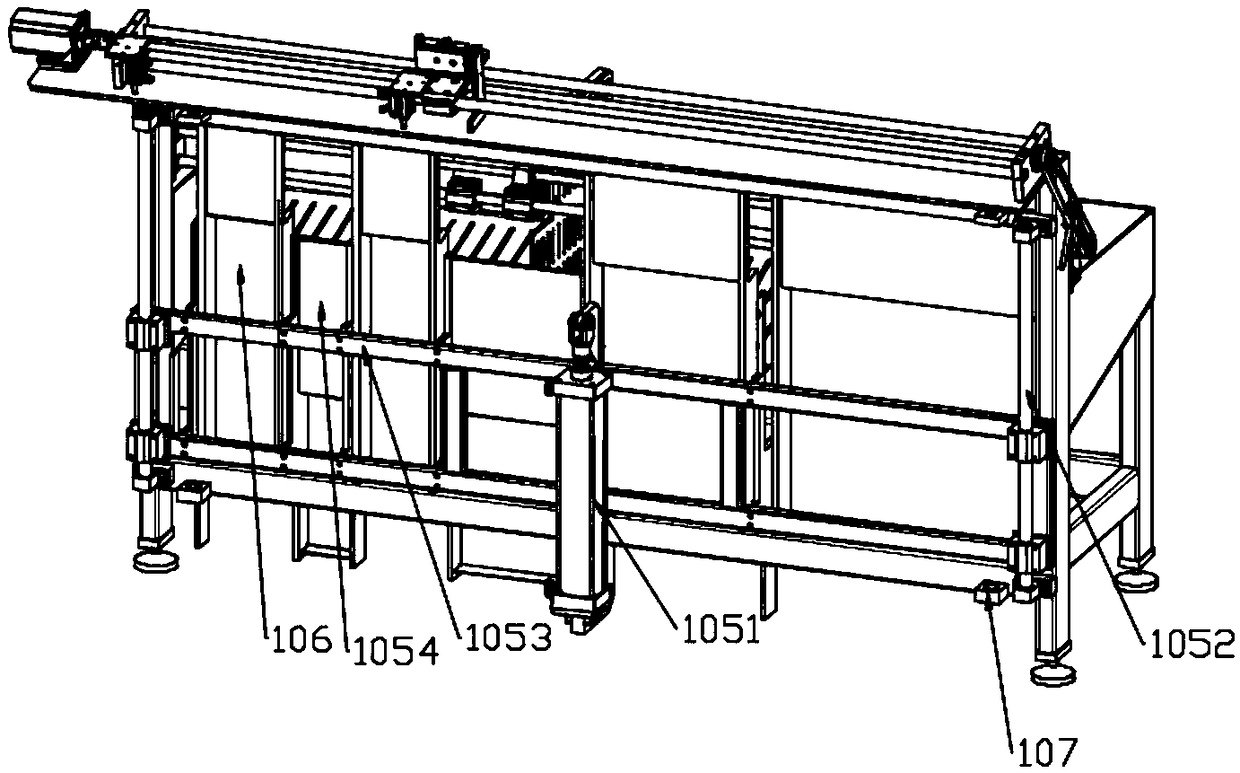

[0031] Such as Figure 1-9 As shown, an automatic feeding double punching machine includes a double punching machine 200 and an automatic feeding device 100 , and the double punching machine 200 is connected to the automatic feeding device 100 by setting a material guide mechanism 300 .

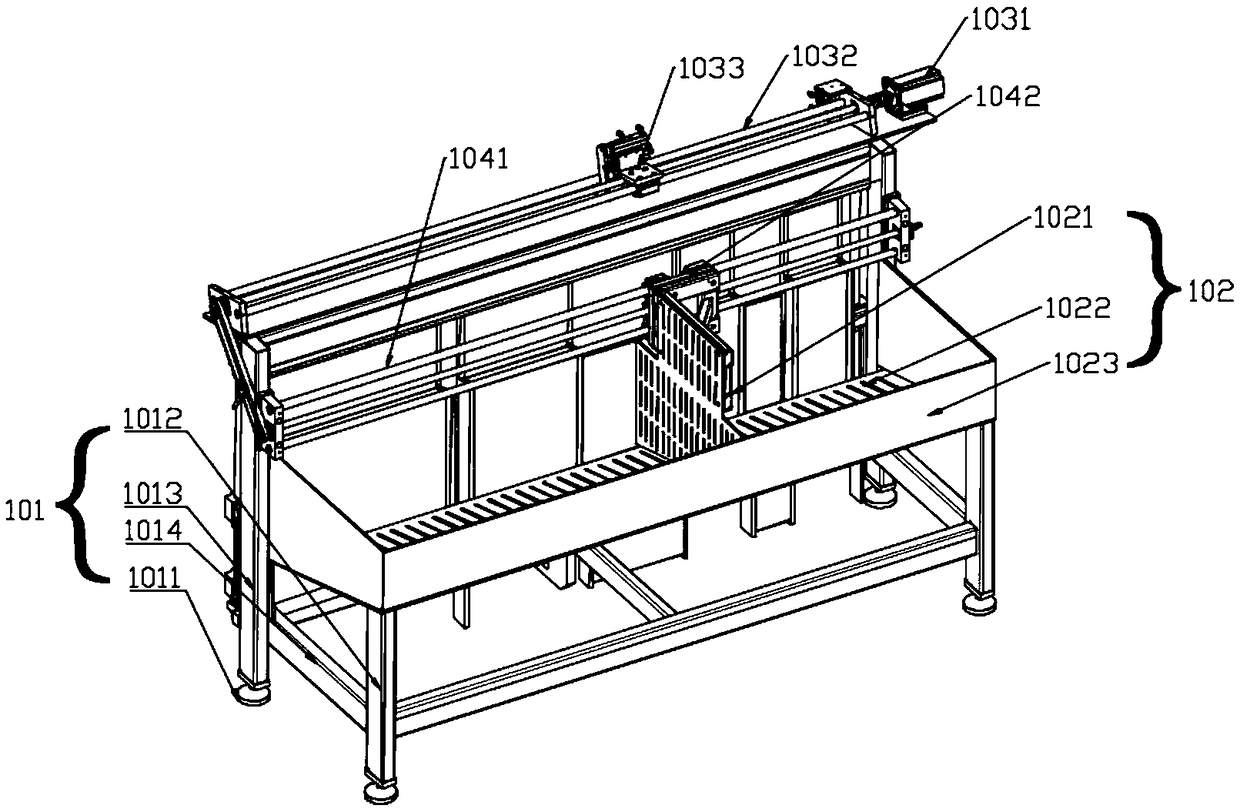

[0032] The automatic feeding device 100 includes a frame 101, a feed bin 102 fixed above the frame 101 and a lifting mechanism, the feed bin 102 includes a baffle plate 1023 and a base plate 1022, and the frame 101 consists of a first column 1013, a second column 1012 and several beams 1014, the first column 1013 is higher than the second column 1012, the silo 102 is fixed on the top of the second column 1012 and connected to the first column 1013 The side wall of the bottom plate 1022 is provided with a gap near the end of the first column 1013. The width of the gap is at least larger than the pipe diameter of the processed pipe, and the bottom plate 1022 is inclined toward the bottom of the...

Embodiment 2

[0037] This embodiment is further optimized on the basis of Embodiment 1. Specifically, the second positioning plate 1042 is provided with a slot along the vertical direction, and the slot is connected with a positioning partition 1021. The required size is adjusted and positioned to avoid chaotic jamming of the workpiece to be processed in the gap, resulting in equipment crash.

Embodiment 3

[0039] This embodiment is further optimized on the basis of Embodiment 1. Specifically, the bottom plate 1022 and / or the positioning partition 1021 are hollow plates, which can dissipate heat and prevent excessive impurities from falling into the gap from the bottom plate. Affect the operation of the lifting mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com