Light rare earth magnetic composite activated charcoal as well as preparation method and application thereof

A composite activation and biochar technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problem of limited treatment effect of quinolone antibiotics, difficult separation and recovery of groundwater remediation materials, and specific surface area Low-level problems, to achieve significant adsorption effect, simple preparation method, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

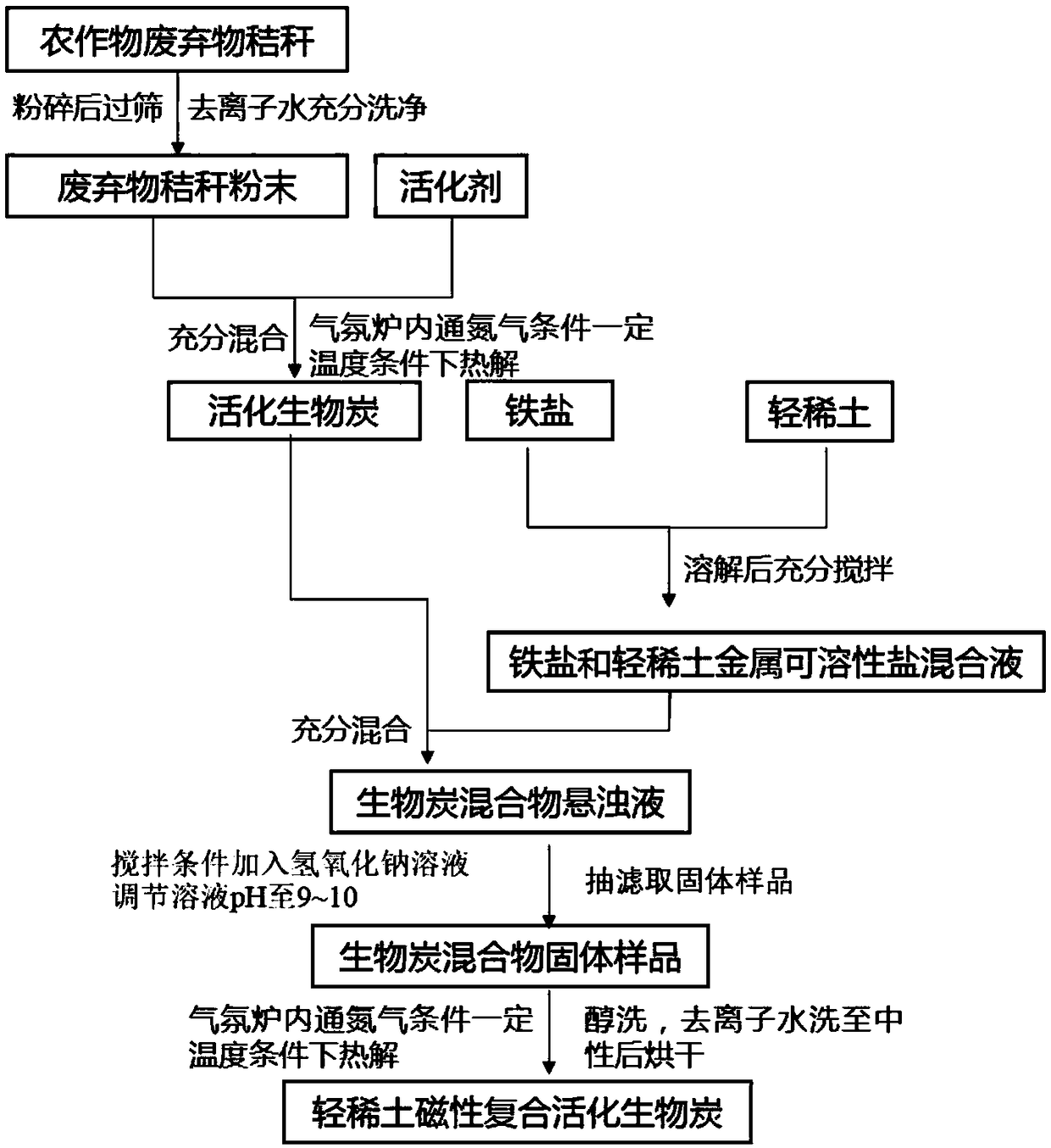

[0034] according to figure 1 The flow chart shown prepares light rare earth magnetic composite activated biochar:

[0035] Step 1: After removing impurities from corn stalks, fully wash them with deionized water, put them in an oven and dry them at 60-80°C for 24 hours, and then crush them through a 100-mesh sieve with a plant grinder to obtain straw powder;

[0036] Step 2: mix the straw powder obtained in step 1 with zinc chloride according to the mass ratio of 4:1, place in a tube furnace, feed nitrogen into the tube furnace at a flow rate of 400mL / min, and then flow at 4°C / min Heat up to 700°C, pyrolyze for 4 hours, cool down to room temperature naturally, take out, wash with ethanol first, then wash with deionized water until neutral, and dry at 60-80°C to obtain activated biochar;

[0037] Step 3: fully impregnate the activated biochar obtained in step 2 with a mixture of iron salt and light rare earth metal soluble salt, the mixing mass volume ratio is 4:50, to ensure ...

Embodiment 2

[0041] Step 1: After removing impurities from corn stalks, fully wash them with deionized water, put them in an oven and dry them at 60-80°C for 24 hours, and then crush them through a 100-mesh sieve with a plant grinder to obtain straw powder;

[0042] Step 2: mix the straw powder obtained in step 1 with zinc chloride at a mass ratio of 5:1, place in a tube furnace, feed nitrogen into the tube furnace at a flow rate of 400mL / min, and then feed nitrogen gas at a flow rate of 3°C / min. Heat up to 800°C, pyrolyze for 5 hours, cool down to room temperature naturally, take out, wash with ethanol first, then wash with deionized water until neutral, and dry at 60-80°C to obtain activated biochar;

[0043] Step 3: fully impregnate the activated biochar obtained in step 2 with a mixture of iron salt and light rare earth metal soluble salt, the mixing mass volume ratio is 5:50, to ensure that the activated biochar is completely submerged, and the iron salt and light rare earth metal solu...

Embodiment 3

[0047] Step 1: After removing impurities from corn stalks, fully wash them with deionized water, put them in an oven and dry them at 60-80°C for 24 hours, and then crush them through a 100-mesh sieve with a plant grinder to obtain straw powder;

[0048] Step 2: mix the straw powder obtained in step 1 with phosphoric acid according to the mass volume ratio of 4:40, place in a tube furnace, feed nitrogen into the tube furnace at a flow rate of 400mL / min, and then flow at 5°C / min Heat up to 1000°C, pyrolyze for 3 hours, cool down to room temperature, take out, wash with ethanol first, then wash with deionized water until neutral, and dry at 60-80°C to obtain activated biochar;

[0049] Step 3: The activated biochar obtained in step 2 is fully impregnated with a mixture of iron salt and light rare earth metal soluble salt, the mixing mass volume ratio is 3:50, to ensure that the activated biochar is completely submerged, and the iron salt and light rare earth metal soluble salt are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com