Processing method for reducing color change of fresh corn

A color change and processing method technology, which is applied to the functions of food ingredients, food ingredients as antimicrobial preservation, food preservation, etc., can solve the problems of taste defects of mature corn kernels, disappearance of stickiness, and degradation of normal temperature storage quality, etc. problems, to achieve the effect of ensuring the taste and color stability, preventing the formation of nitrite, and improving storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

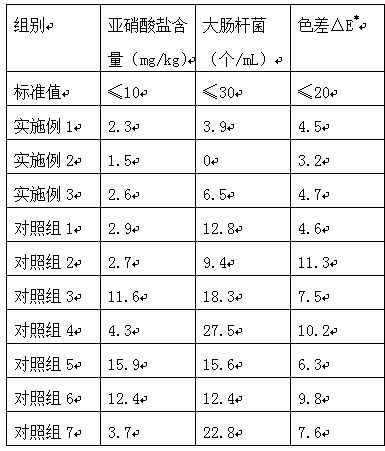

Examples

Embodiment 1

[0019] A processing method for reducing the color change of fresh corn, comprising the following content:

[0020] (1) Keep 1-2 layers of bracts from the collected fresh corn, soak them in salt water with a mass concentration of 4% for 45 minutes, wash them after completion, and drain the water for later use;

[0021] (2) Put the above-mentioned treated fresh corn into edible alkaline water with a mass concentration of 5%, boil it for 25 minutes, remove it, and put it in cold boiled water with a temperature of 2°C for 35 minutes;

[0022] (3) Put the above-mentioned treated fresh corn into the dipping solution, and ultrasonically treat it for 12 minutes at a temperature of 50°C and a power of 350W;

[0023] The soaking solution includes the following raw materials in parts by weight: 14 parts of natural propolis, 4 parts of bee pollen processing material, 5 parts of coriander root extract, 2 parts of eggplant stalk extract, 1 part of vitamin C, 2.5 parts of tea polyphenols, 4....

Embodiment 2

[0032] A processing method for reducing the color change of fresh corn, comprising the following content:

[0033] (1) Keep 1-2 layers of bract leaves from the collected fresh corn, soak them in salt water with a mass concentration of 2% for 60 minutes, wash them after completion, and drain the water for later use;

[0034] (2) Put the above-mentioned treated fresh corn into edible alkaline water with a mass concentration of 4%, boil it for 30 minutes, remove it, and put it in cold boiled water with a temperature of 3°C for 30 minutes;

[0035] (3) Put the above treated fresh corn into the soaking liquid, and ultrasonically treat it for 8 minutes at a temperature of 45°C and a power of 400W;

[0036] The soaking solution includes the following raw materials in parts by weight: 12 parts of natural propolis, 5 parts of bee pollen processing material, 4 parts of coriander root extract, 3 parts of eggplant stalk extract, 1.4 parts of vitamin C, 2.2 parts of tea polyphenols, 6 part...

Embodiment 3

[0045] A processing method for reducing the color change of fresh corn, comprising the following content:

[0046] (1) Keep 1-2 layers of bracts from the collected fresh corn, soak them in salt water with a mass concentration of 6% for 30 minutes, wash them after completion, and drain the water for later use;

[0047] (2) Put the above-mentioned treated fresh corn into edible alkaline water with a mass concentration of 6%, boil it for 20 minutes, remove it, and put it in cold boiled water with a temperature of 1°C for 40 minutes;

[0048] (3) Put the above treated fresh corn into the soaking liquid, and ultrasonically treat it for 16 minutes at a temperature of 55°C and a power of 300W;

[0049] The soaking solution includes the following raw materials in parts by weight: 16 parts of natural propolis, 3 parts of bee pollen processing material, 6 parts of coriander root extract, 1 part of eggplant stalk extract, 0.6 part of vitamin C, 2.8 parts of tea polyphenols, 3 parts of sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com