Simulation experiment method and device for high temperature and high pressure reservoir corrosion

A simulation experiment device and simulation experiment technology, which are applied in the simulation experiment method and device of high temperature and high pressure reservoir dissolution, and the field of experiment method and device, can solve the problems of affecting the experimental conclusion, unable to achieve real formation conditions, unable to choose the dissolution method, etc. To achieve the effect of accurate judgment results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

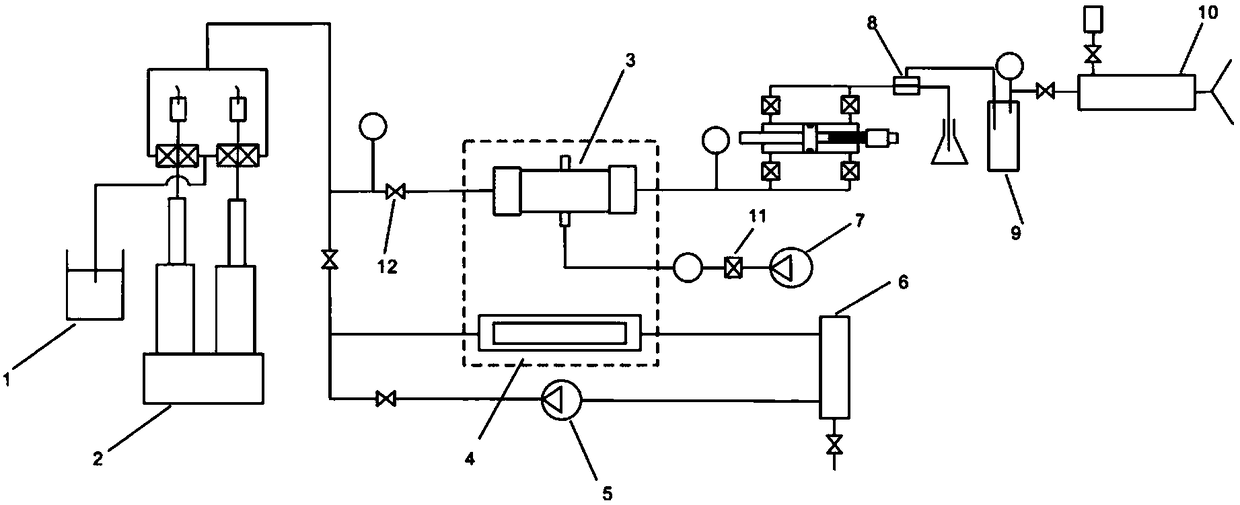

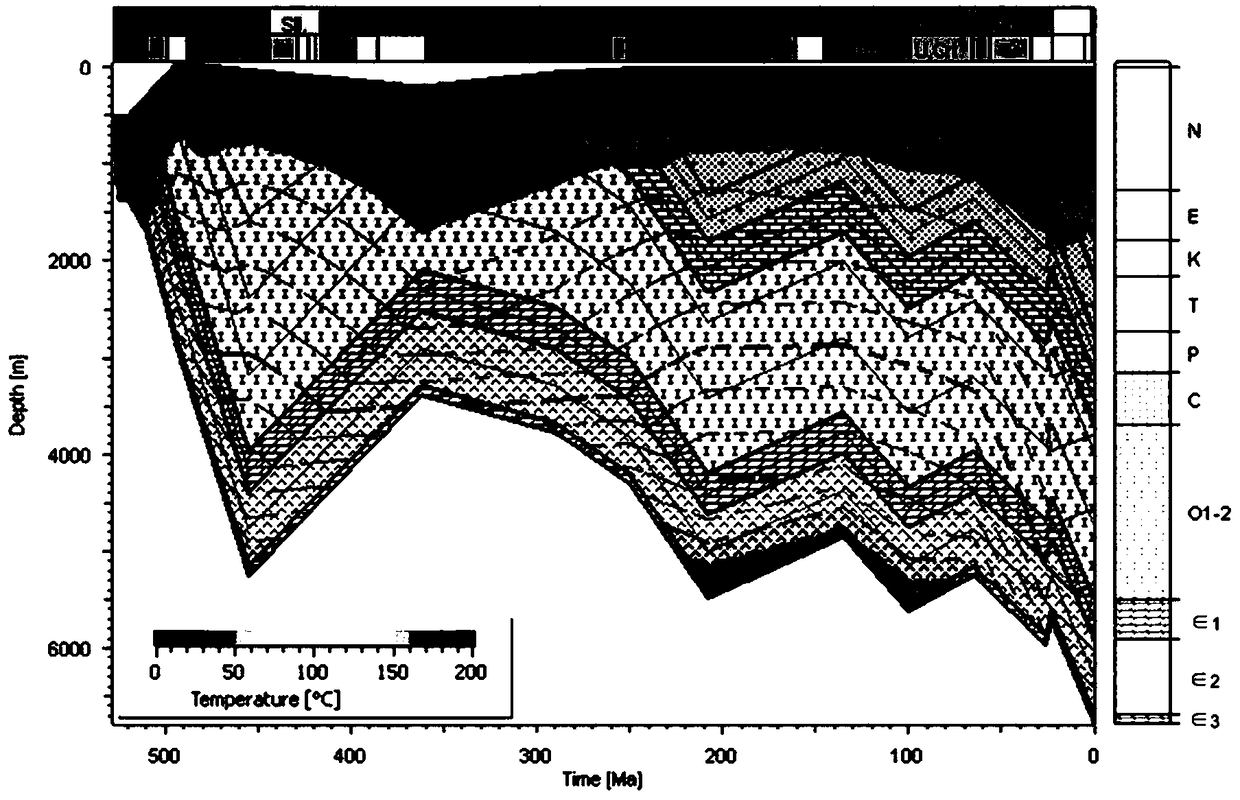

[0082] In order to predict whether oil and gas reservoirs are developed in the Middle and Lower Cambrian in the Kalping area, where the degree of exploration in the Tarim Basin is very low, and to provide guidance for the block bidding work in this area. This embodiment provides a simulation experiment method, which is through figure 1 The shown device is completed, specifically comprising the following steps:

[0083] Fresh samples collected from outcrops in the field were processed to make a standard plunger sample with a diameter of 2.474 cm and a length of 4.117 cm. Both ends of the plunger sample were ground flat and the end face was perpendicular to the cylinder. After drying at 200°C for 4 hours, the sample was weighed, and the weight was 55.045g. The measured porosity is 10.97%, and the permeability is 4.2mD.

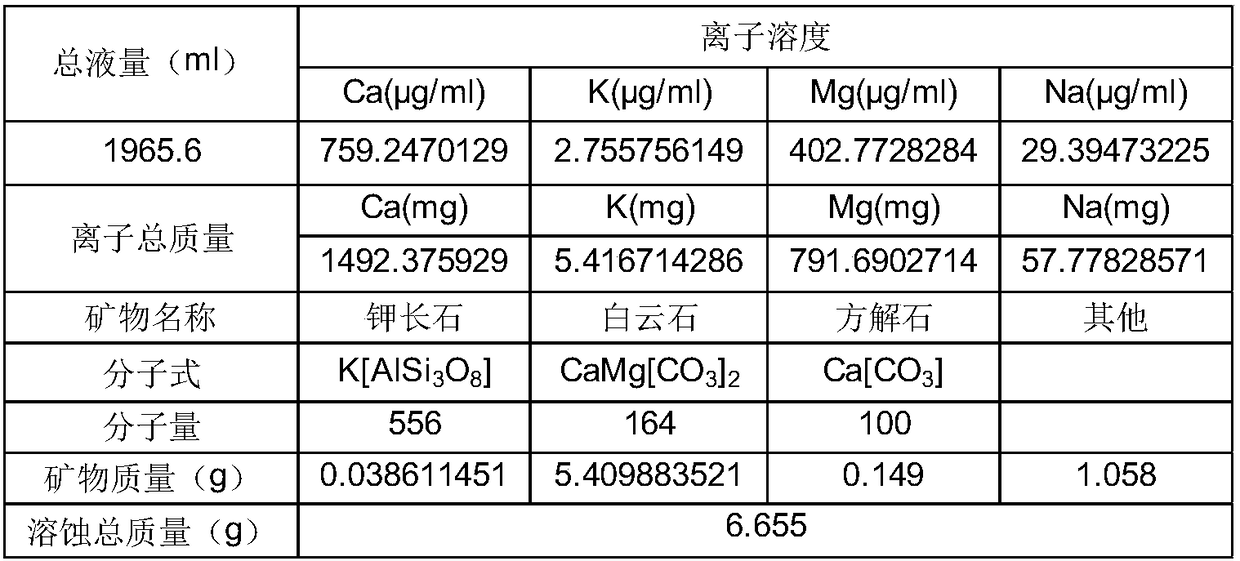

[0084] Carry out X-ray diffraction analysis to this sample, measure its component, and component data is shown in Table 1

[0085] Table 1 Sample X-ray diffr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com