Wear-resistance testing mechanism for rice cooker liner coating

A wear resistance test and rice cooker technology, which is applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of test failure, increase the centrifugal force of the cooking container, and fall off the cooking container, so as to improve the efficiency and success rate and reduce the test error. source, the effect of reducing the installation burden

Pending Publication Date: 2018-12-07

丁成华 +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Based on the test method and requirements for testing the wear resistance of the inner tank coating of the rice cooker in the QB / T 4099-2010 standard of "Electric Cooker and Similar Appliances", there are obvious defects in the prior art, that is, the gap between the cooking container and the base turntable. Because of the installation positioning error, the coaxiality error will be generated. During the test process, the error will amplify the centrifugal force generated by the rotation, and the uncooked rice used as abrasive in the cooking container will aggregate under the action of centrifugal force because it is unconstrained. The eccentricity of the mass will further increase the centrifugal force on the cooking vessel, and the centrifugal force will gradually increase throughout the test process until the binding force of the cooking vessel is broken, causing the cooking vessel to fall off, resulting in test failure

[0003] In addition, the centrifugal force generated by the rotation of the cooking container causes the raw rice inside as an abrasive to gather around, thereby reducing the amount of raw rice participating in the friction of the coating of the inner tank, and the purpose of better testing the wear resistance of the coating cannot be achieved.

[0004] To sum up, there are obvious uncertain factors in the original recommended scheme, the reproducibility of test results is poor, and it is more likely to cause test failure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

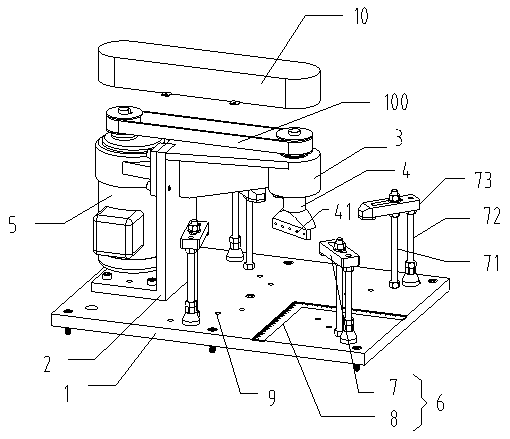

[0015] A kind of wear-resisting test mechanism of the liner coating of electric cooker, such as figure 1 As shown, it includes a workbench 1 , a base fixing part 2 , a bearing 3 , a stirring part 4 , a motor 5 and a test piece fixing assembly 6 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a wear-resistance testing mechanism for a rice cooking liner coating. The mechanism comprises a workbench, a base fixing part, a bearing, a stirring part, a motor and a test part fixing component, wherein the base fixing part is fixed on one side of the workbench, the motor is fixed at one end of the base fixing part, and the bearing is connected with the other end of the base fixing part; the stirring part is fixed by the bearing; a synchronous pulley at the upper end of the stirring part is connected with the synchronous pulley of the motor through a synchronous toothed belt, and a stirring plate connecting part is arranged at the lower end of the stirring part; the testing part fixing component comprises fixing devices which are arranged at four corners and are in centrosymmetric, and a ruler which is vertically arranged by taking the symmetric center point as the reference point; and the stirring plate connecting part is positioned right above the symmetriccenter point. The wear-resistance testing mechanism has a reasonable structural design, adopts an upper action execution mechanism and a lower work platform to eliminate the interference of centrifugal force in motion on the testing result to improve the testing efficiency and success rate and reduce the testing error source, so that the testing result has relatively high reproducibility and consistency.

Description

technical field [0001] The invention relates to the field of electric rice cooker testing, in particular to a mechanism for testing the wear resistance of the inner tank coating of the electric rice cooker. Background technique [0002] Based on the test method and requirements for testing the wear resistance of the inner tank coating of the rice cooker in the QB / T 4099-2010 standard of "Electric Cooker and Similar Appliances", there are obvious defects in the prior art, that is, the gap between the cooking container and the base turntable. Because of the installation positioning error, the coaxiality error will be generated. During the test process, the error will amplify the centrifugal force generated by the rotation, and the uncooked rice used as abrasive in the cooking container will aggregate under the action of centrifugal force because it is unconstrained. The eccentricity of the mass will further increase the centrifugal force on the cooking container, and the centr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N3/56

CPCG01N3/56G01N2203/0282

Inventor 丁成华任志伟陈兴慧范国锋

Owner 丁成华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com