Cantilever end control device and control method for towing construction of curved light I-beam bridge

A control device and I-beam technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem of large deflection at the cantilever end of the main girder, which is difficult to reduce the negative bending moment of the fulcrum of the beam body, and the deformation of the inner and outer ends of the beam end Inconsistency, inability to be at the same elevation, etc., to achieve the effect of less difficulty in connection, light weight, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

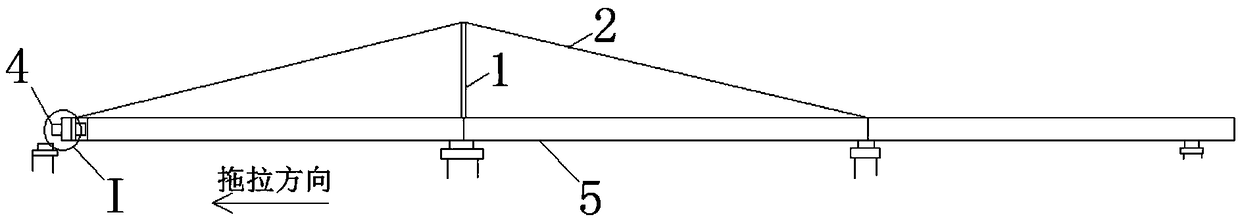

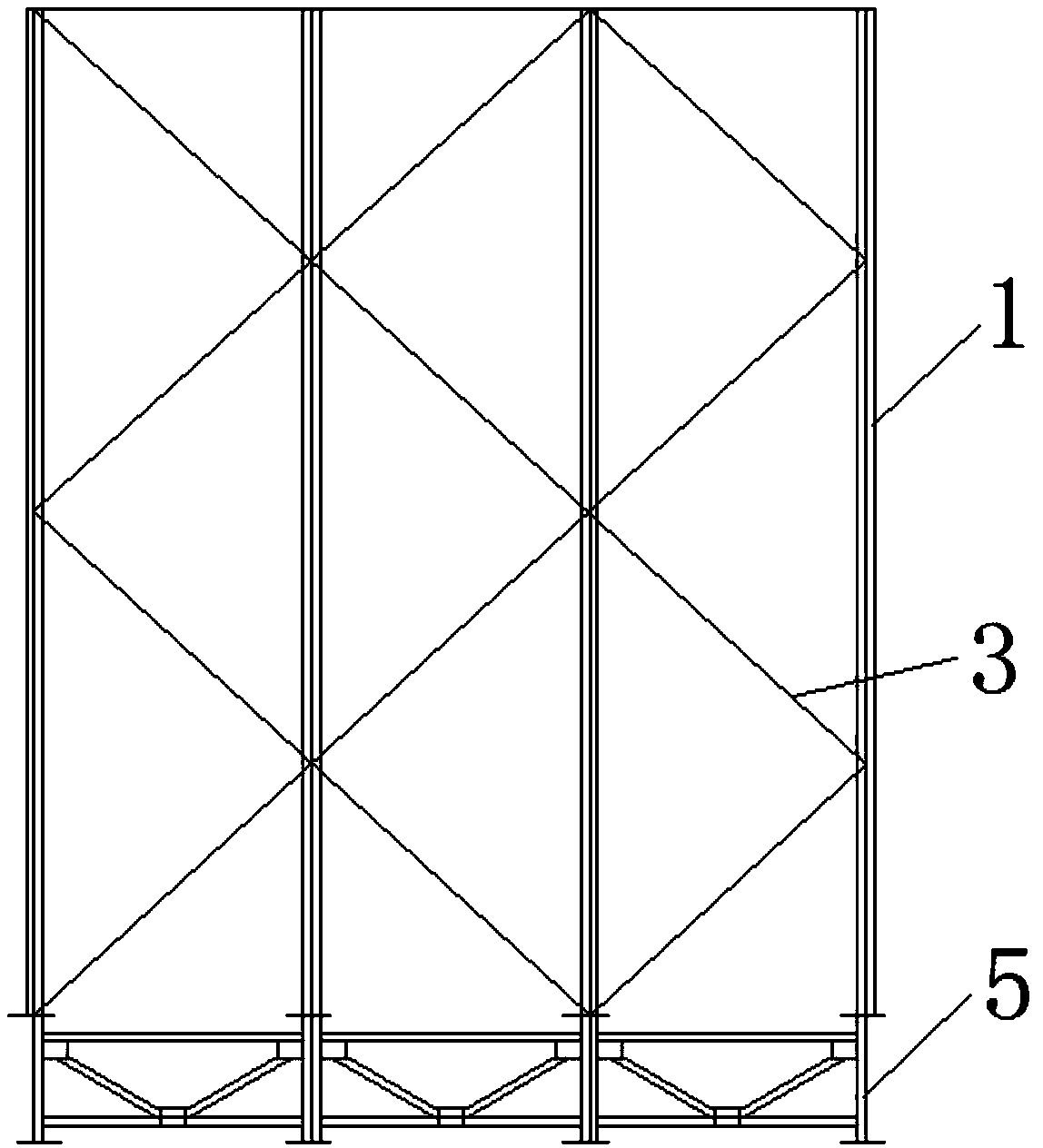

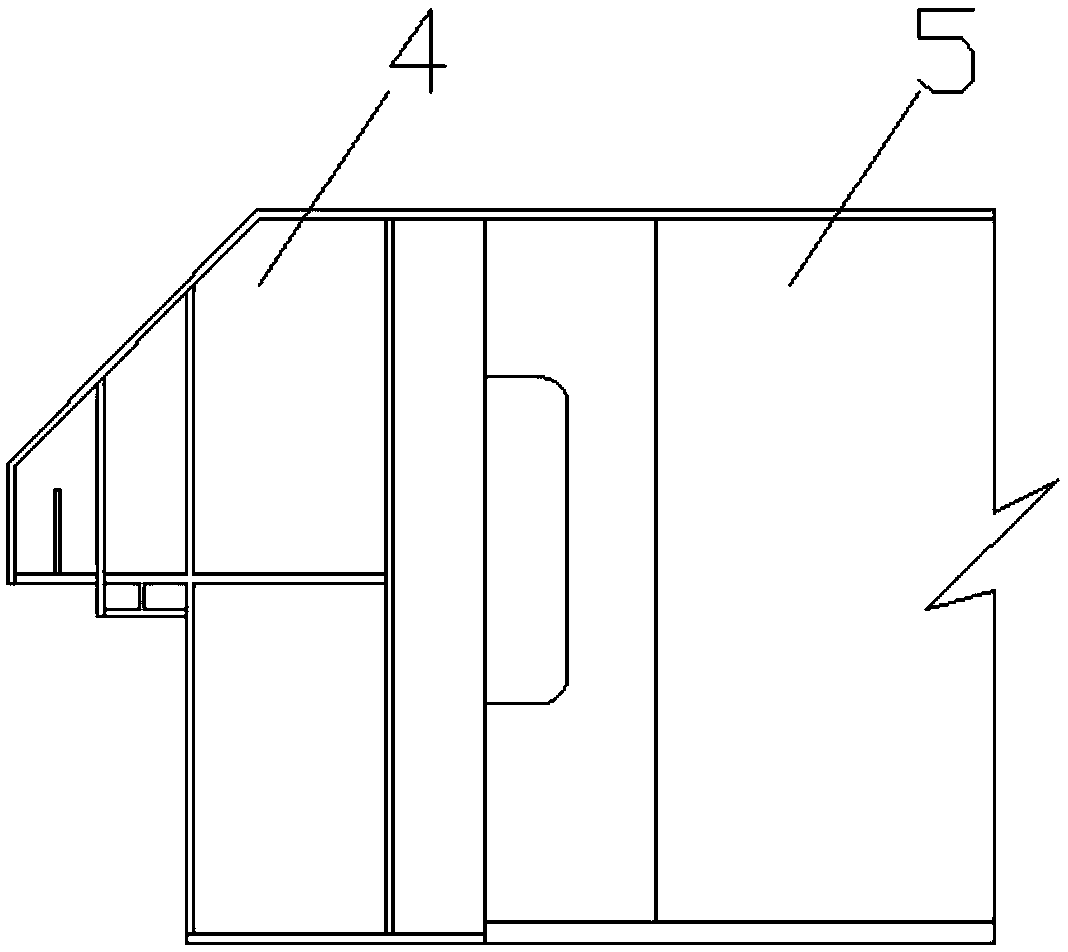

[0021] The invention provides a cantilever end control device for the dragging construction of a curved light-duty I-shaped steel girder bridge (referred to as the device, see Figure 1-3 ), it is characterized in that the device includes a tower 1, a drag cable 2 and a short nose bridge 4; a tower 1 is installed on each longitudinal I-beam of the I-beam 5, and the tower 1 is located at the front two spans of the I-beam 5 in the pulling direction At the middle beam, several towers 1 are evenly arranged along the direction of the bridge; the towers 1 are connected by tower connectors 3 to form a tower frame; one end of the cable 2 is connected to the short nose bridge 4 by a connector, and the middle part is erected on the tower 1. The top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com