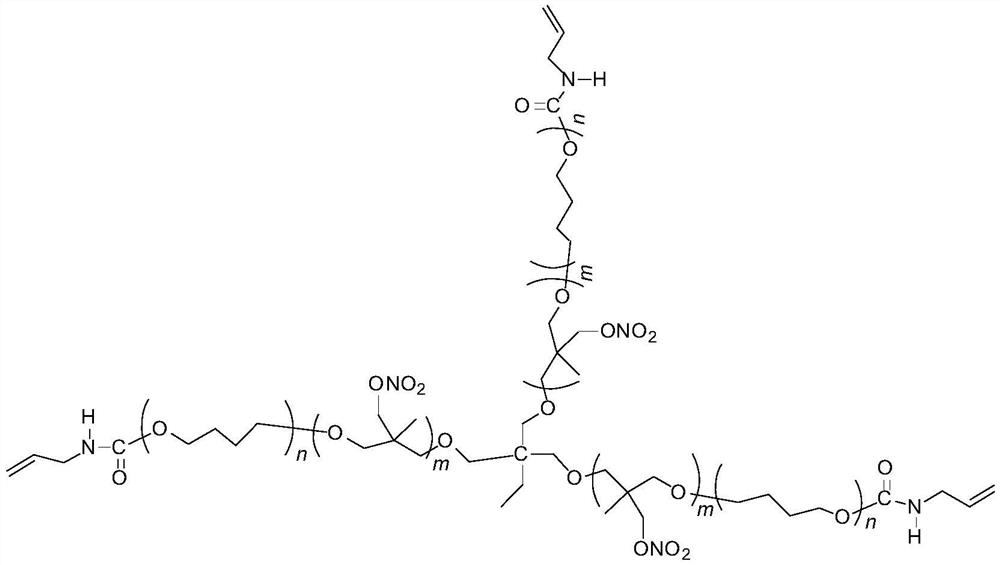

A kind of trifunctional end alkenyl copolyether energetic adhesive and its synthesis method

A technology of terminal alkenyl copolyether and trifunctionality, applied in the direction of polyether adhesive, adhesive type, adhesive, etc., which can solve the problem of lack of energy in elastomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

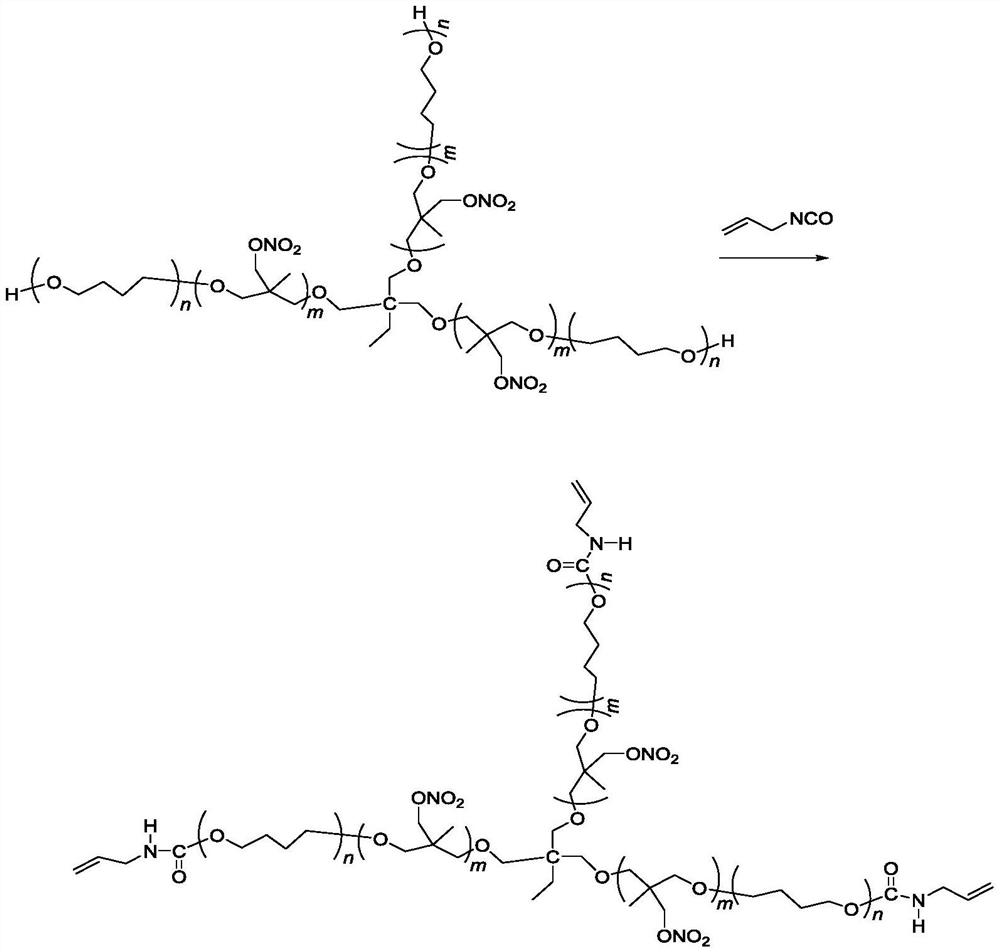

Method used

Image

Examples

Embodiment 1

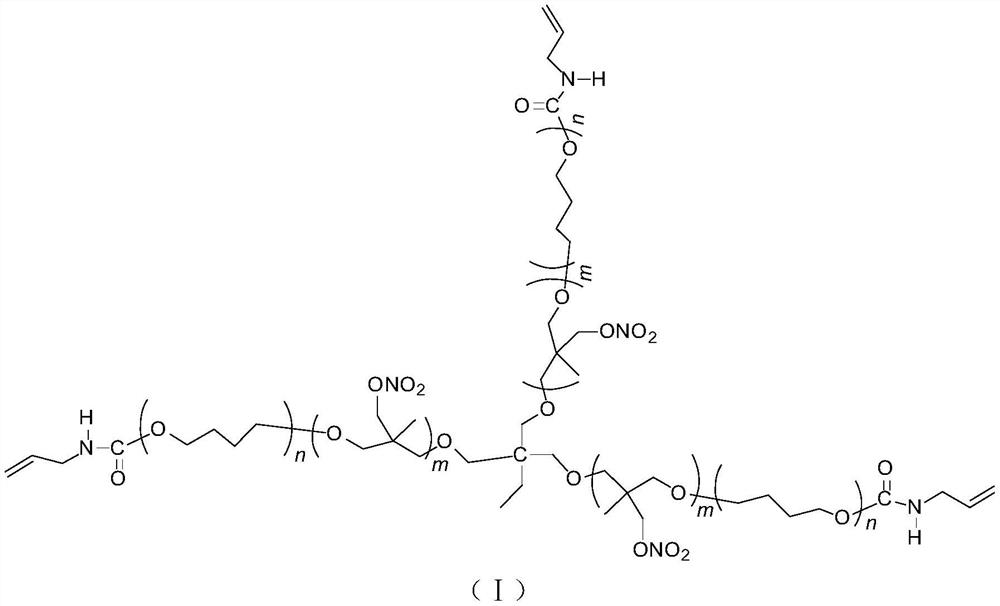

[0021] Add 16.87g (5mmol) trifunctional NIMMO-THF copolyether in a four-neck round bottom flask equipped with mechanical stirring, reflux condenser, thermometer, and dropping funnel, and at a temperature of 50°C, add 1.25g ( 15mmol) of 3-propene isocyanate, the time of dropping was 10min, after the dropwise addition was completed, the temperature was raised to 77°C to continue the reaction for 12h, and the unreacted 3-propene isocyanate was removed under reduced pressure to obtain 18.12g of light yellow viscous liquid.

[0022] Structure Identification:

[0023] IR, ν max (cm -1 ): 3443 (-NH), 1727 (-C=O), 1518 (amide II peak C-N-H), 1112 (fatty ether C-O-C), 1632, 1281, 869 (-ONO 2 ).

[0024] 1 H NMR (CDCl 3 ,500MHz): δ5.70~5.80(=CH-),5.20~5.30(=CH 2 ),4.39~4.41(-CH 2 ONO 2 ),4.01(-CH 2 -NH-),3.80(-O-CH 2 -),3.25~3.42(-CH 2 -O-CH 2 -),1.58~1.62(-CH 2 -CH 2 -),0.96~1.00(-CH 3 );

[0025] 13 C NMR (CDCl 3 ,125MHz): δ155.9, 134.3, 116.3, 75.1, 73.7, 70.6, 43.5...

Embodiment 2

[0028] Add 16.87g (5mmol) trifunctional NIMMO-THF copolyether in a four-necked round bottom flask equipped with mechanical stirring, reflux condenser, thermometer, and dropping funnel, and at a temperature of 50°C, add 1.33g ( 16mmol) of 3-propene isocyanate, the time of dropping is 10min, after the dropwise addition is completed, the temperature is raised to 77°C to continue the reaction for 16h, and the unreacted 3-propene isocyanate is removed under reduced pressure to obtain 18.15g of light yellow viscous liquid, namely Trifunctional alkenyl-terminated copolyether energetic adhesive.

Embodiment 3

[0030] Add 16.87g (5mmol) trifunctional NIMMO-THF copolyether in a four-necked round bottom flask equipped with mechanical stirring, reflux condenser, thermometer, and dropping funnel, and at a temperature of 50°C, add 1.41g ( 17mmol) of 3-propene isocyanate, the time of dropping is 10min, after the dropwise addition is completed, the temperature is raised to 77°C to continue the reaction for 18h, and the unreacted 3-propene isocyanate is removed under reduced pressure to obtain 18.21g of light yellow viscous liquid, namely Trifunctional alkenyl-terminated copolyether energetic adhesive.

[0031] Application properties of the trifunctional alkenyl-terminated copolyether energetic adhesive of the present invention

[0032] 1) Curing temperature

[0033] The trifunctional alkenyl-terminated copolyether energetic adhesive prepared by the present invention is cured with trimethylisophthalonitrile oxide, and the required curing temperature is compared with other curing systems as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com