Low temperature construction asphalt planting roof root blocking material and preparation and construction method thereof

A root-resistance and asphalt technology, which is applied in low-temperature construction of asphalt planting roof root-resistance materials and its preparation and construction, can solve the problems of no obvious improvement in smoke pollution and the need for heavy machinery in construction, so as to improve high-temperature deformation resistance and Effects of tear strength, shortened construction period, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

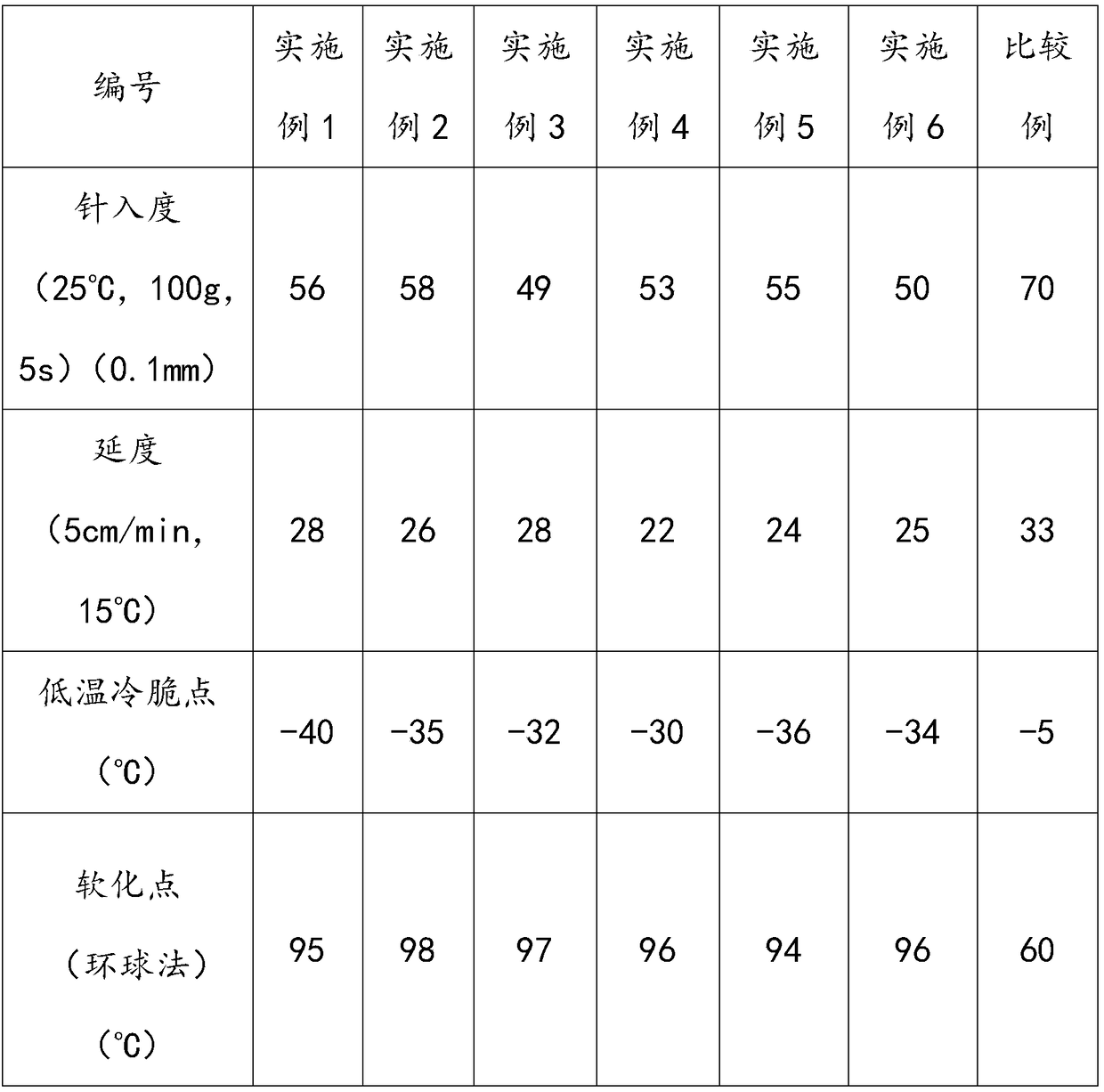

Examples

Embodiment 1

[0028] Step 1: Add 20 parts of diesel oil to 100 parts of base petroleum asphalt, and change the base petroleum asphalt into a viscous flowable slurry by stirring and dissolving at a temperature of 40°C.

[0029] Step 2: Add 10 parts of methyl methacrylate, 1 part of butadiene and 1 part of octyl dichlorophenoxypropionate to the slurry in step 1 respectively, and mix them evenly through continuous mechanical shearing and stirring to obtain Reaction matrix slurry.

[0030] Step 3: Add 1 part of methyl vinyl ketone to the reaction matrix slurry in step 2, and further mix uniformly by mechanical shearing and stirring to obtain a root-blocking material.

[0031] The above-mentioned parts are parts by weight.

Embodiment 2

[0033] Step 1: Add 30 parts of a mixture of diesel oil and epoxidized soybean oil to 100 parts of base petroleum asphalt, and through stirring and dissolving at a temperature of 50° C., the base petroleum asphalt becomes a viscous flowable slurry.

[0034] Step 2: Add 20 parts of propyl methacrylate, 2 parts of butadiene and its derivatives, and 2 parts of octyl dichloromethylphenoxypropionate to the slurry in step 1, and through continuous mechanical shearing Stir and mix evenly to obtain a reaction matrix slurry.

[0035] Step 3: Add 2 parts of benzoin to the reaction matrix slurry in step 2, and further mix uniformly by mechanical shearing and stirring to obtain a root-blocking material.

[0036] The above-mentioned parts are parts by weight.

Embodiment 3

[0038] Step 1: Add 30 parts of diesel oil to 100 parts of base petroleum asphalt, and make the base petroleum asphalt into a viscous flowable slurry by stirring and dissolving at a temperature of 50°C.

[0039] Step 2: Add 10 parts of butyl methacrylate, 1 part of 1,3-dimethylbutadiene and 1 part of octyl dichlorophenoxypropionate to the slurry in step 1, and pass through the continuous mechanical Shear and stir to mix evenly to obtain a reaction matrix slurry.

[0040] Step 3: Add 1 part of benzophenone into the reaction matrix slurry in step 2, and further mix uniformly by mechanical shearing and stirring to obtain a root-blocking material.

[0041] The above-mentioned parts are parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com