A kind of black pigment applied to remote control receiving panel and its preparation method

A black pigment, remote control receiving technology, applied in the field of pigments, can solve the problems of inconvenience, low far infrared penetration rate, short effective distance of remote control, etc., and achieve the effect of low absorption rate and improved remote control distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides a kind of preparation method of the black pigment that is applied to the remote control receiving panel, and it comprises the following steps:

[0026] (A) Stir the blue colorant, purple colorant, yellow colorant, red colorant and dispersant evenly to obtain the first mixture, wherein 1-100 parts of blue colorant and 1-50 parts of purple colorant , 1-50 parts of yellow colorant, 1-50 parts of red colorant, 5-300 parts of dispersant;

[0027] (B) Add plastic substrate to the first mixture and stir evenly to obtain the second mixture, wherein the plastic substrate is polyethylene, polypropylene, polycarbonate resin, polymethacrylate and acrylonitrile-butadiene-styrene copolymer One or a mixture of two or more polymers;

[0028] (C) Injecting or extruding the second mixture to obtain the black pigment in powder or granular form.

[0029] The black pigment prepared by the present invention is made into a transparent or translucent black...

Embodiment 1

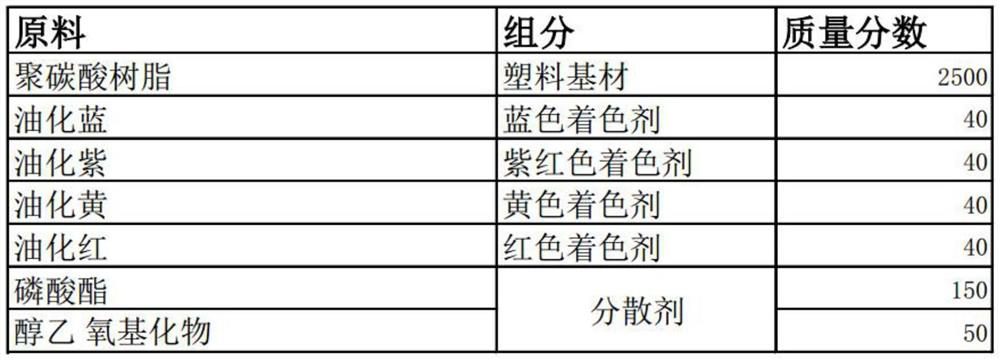

[0032] The composition of the black pigment applied to the remote control receiving panel of embodiment 1 is as shown in table 1:

[0033] raw material components quality score Acrylonitrile-Butadiene-Styrene Copolymer plastic substrate 2500 oily blue blue colorant 60 Oil Violet fuchsia colorant 40 oily yellow yellow colorant 30 oil red red colorant 30 Alkylphenol polyvinyl ether Dispersant 100

[0034] Table 1

Embodiment 2

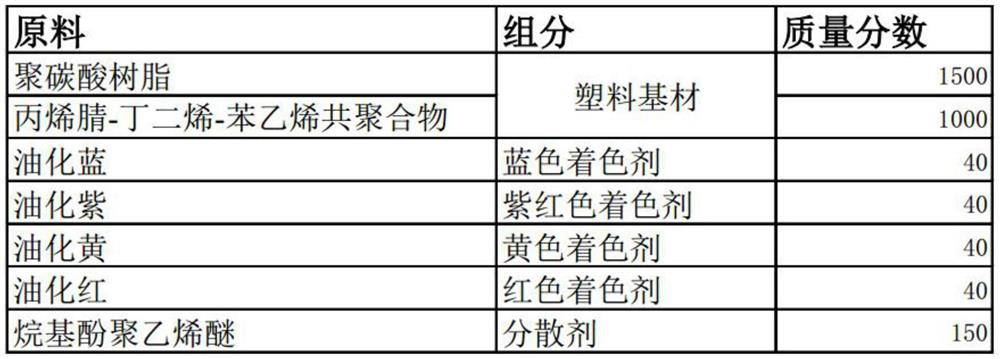

[0036] The composition of the black pigment applied to the remote control receiving panel of embodiment 2 is as shown in table 2:

[0037]

[0038] Table 2

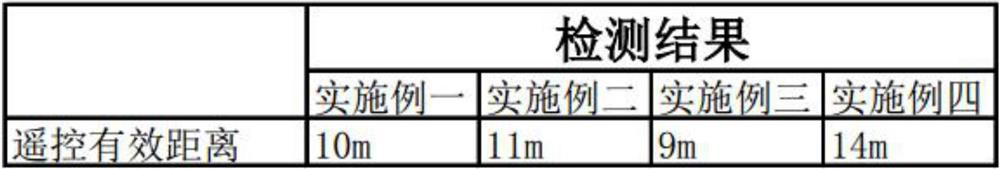

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com