Phthalic anhydride-modified polycarboxylic acid water reducing agent and preparation method thereof

A technology of polycarboxylic acid and water reducer, which is applied in the field of concrete admixtures, can solve problems such as difficulty in meeting performance requirements, reduction of free water content, single function of large monomers, etc., to achieve increased size, enhanced dispersion, enhanced The effect of steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

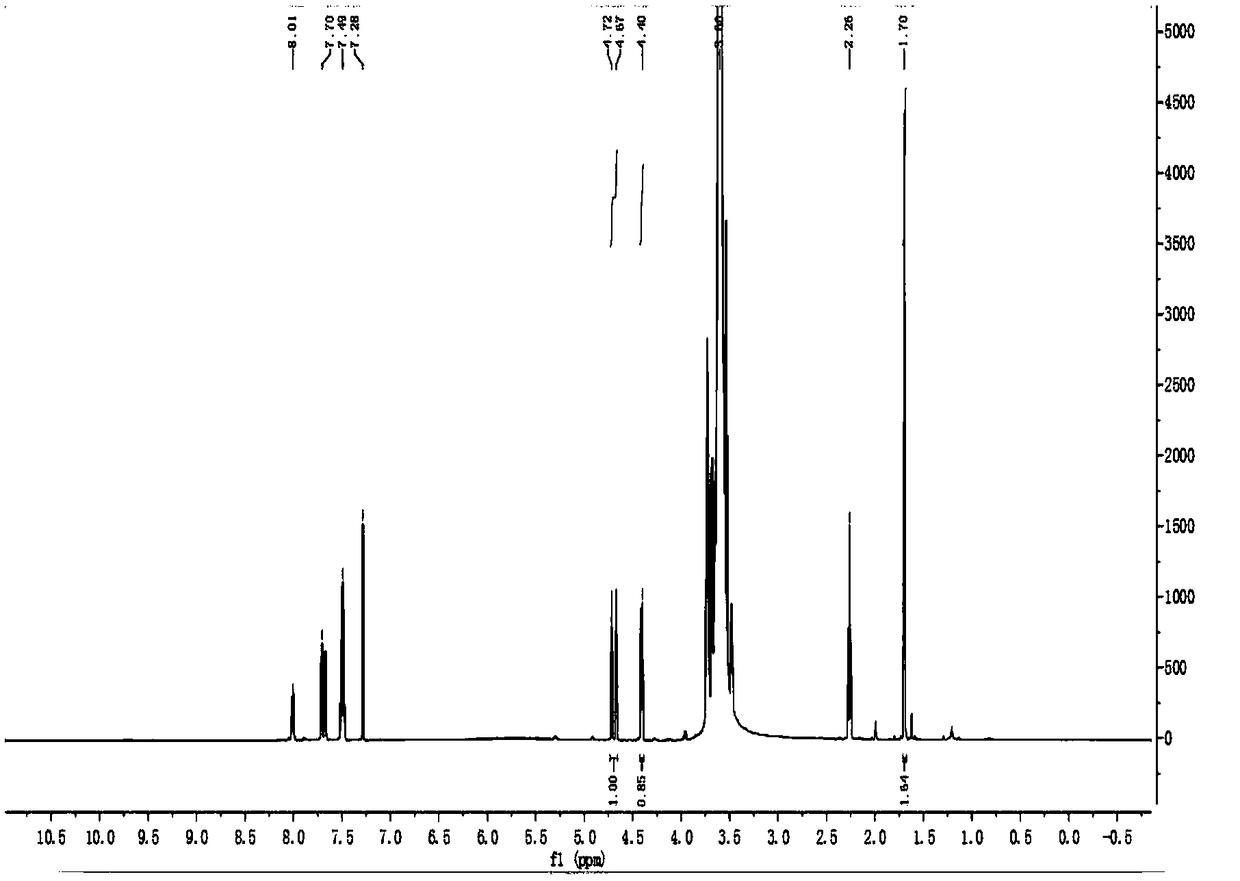

Image

Examples

Embodiment 1

[0027] A phthalic anhydride modified polycarboxylate water reducer and a preparation method thereof, comprising the following steps:

[0028] a. Weigh phthalic anhydride and methallyl polyoxyethylene ether in a three-necked flask, put a magnetic stirrer, place the three-necked flask on a magnetic stirrer, close the three bottlenecks, and react at 5°C for 5 hours, Obtain phthalic anhydride modified macromonomer;

[0029] b. Weigh reducing agent and chain transfer agent in constant pressure dropping funnel A, weigh methacrylic acid in constant pressure dropping funnel B, add deionized water respectively to make the liquid volumes in constant pressure dropping funnels A and B equal, Gently shake the constant pressure dropping funnels A and B to dissolve the contents of the funnels completely;

[0030] c. Weigh the oxidizing agent and put it into the three-necked flask, put the constant pressure dropping funnels A and B on the left and right sides of the three-necked flask respec...

Embodiment 2

[0039] a. Weigh phthalic anhydride and methallyl polyoxyethylene ether into a three-necked flask, put a magnetic stirrer, place the three-necked flask on a magnetic stirrer, close the three bottlenecks, and react at 50-70°C 4.3h, obtain phthalic anhydride modified macromonomer;

[0040] b. Weigh reducing agent and chain transfer agent in constant pressure dropping funnel A, weigh methacrylic acid in constant pressure dropping funnel B, add deionized water respectively to make the liquid volumes in constant pressure dropping funnels A and B equal, Gently shake the constant pressure dropping funnels A and B to dissolve the contents of the funnels completely;

[0041] c. Weigh the oxidizing agent and put it into the three-necked flask, put the constant pressure dropping funnels A and B on the left and right sides of the three-necked flask respectively, and put the condensation reflux device on the middle-mouthed frame, and place the three-necked flask on a magnetic stirrer, and t...

Embodiment 3

[0051]a. Weigh phthalic anhydride and methallyl polyoxyethylene ether into a three-necked flask, put a magnetic stirrer, place the three-necked flask on a magnetic stirrer, close the three bottlenecks, and react at 64°C for 3.7h , to obtain phthalic anhydride modified macromonomer;

[0052] b. Weigh reducing agent and chain transfer agent in constant pressure dropping funnel A, weigh methacrylic acid in constant pressure dropping funnel B, add deionized water respectively to make the liquid volumes in constant pressure dropping funnels A and B equal, Gently shake the constant pressure dropping funnels A and B to dissolve the contents of the funnels completely;

[0053] c. Weigh the oxidizing agent and put it into the three-necked flask, put the constant pressure dropping funnels A and B on the left and right sides of the three-necked flask respectively, and put the condensation and reflux device on the middle mouth frame, and place the three-necked flask on a magnetic stirrer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com