Power-type nickel-zinc ferrite prepared by low-pressure and low-temperature sintering and preparation method thereof

A nickel-zinc ferrite, low-temperature sintering technology, applied in the field of soft ferrite, can solve the problems of long sintering process time and high energy consumption, achieve a flat permeability-temperature curve, uniform grains, and reduce eddy current loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

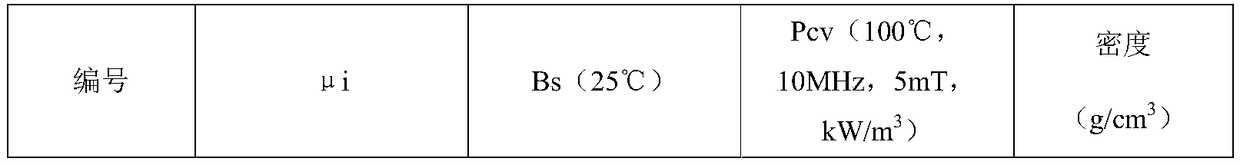

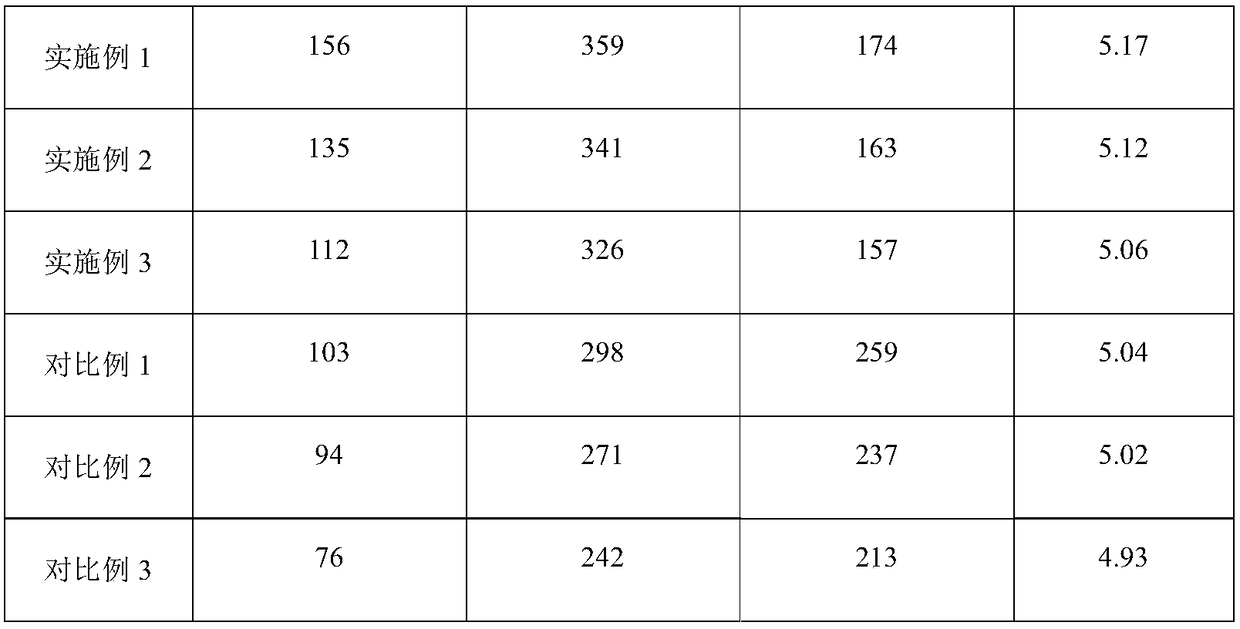

Embodiment 1

[0020] (1) Weigh and mix the main components, and the main components are calculated as Fe by mole percentage 2 o 3 9%, NiO21%, ZnO21%, CuO9%, take out and dry after ball milling for 1.5h.

[0021] (2) Carry out pre-firing in an air atmosphere, the pre-firing temperature is 900°C, and the holding time is 2h.

[0022] (3) According to the total mass of the main components, add subcomponents to the calcined material, the subcomponents are CoO0.06wt%, CaCO 3 0.10wt%, BaO0.03wt%, V 2 o 5 0.02wt%, Bi 2 o 3 0.05wt%, SnO 2 0.10wt%, GeO 2 0.03 wt%.

[0023] (4) Secondary ball milling for 4 hours, after drying, add polyvinyl alcohol solution with a mass concentration of 10% as a binder, the addition amount is mainly 10% of the mass of the component, and zinc stearate is added as a release agent, the addition amount is mainly 0.2% of the mass of the ingredients, granulated, and the sieved -40 mesh particles were taken for molding to obtain a blank.

[0024] (5) The blank is si...

Embodiment 2

[0026] (1) Weigh and mix the main components, and the main components are calculated as Fe by mole percentage 2 o 3 51%, NiO20%, ZnO21%, CuO8%, take out and dry after ball milling for 1.5h.

[0027] (2) Carry out pre-firing in an air atmosphere, the pre-firing temperature is 900°C, and the holding time is 2h.

[0028] (3) According to the total mass of the main components, add subcomponents to the calcined material, the subcomponents are CoO0.10wt%, CaCO 3 0.05wt%, V 2 o 5 0.05wt%, SnO 2 0.05wt%, GeO 2 0.05 wt%.

[0029] (4) Secondary ball milling for 4 hours, after drying, add polyvinyl alcohol solution with a mass concentration of 10% as a binder, the addition amount is mainly 10% of the mass of the component, and zinc stearate is added as a release agent, the addition amount is mainly 0.2% of the mass of the ingredients, granulated, and the sieved -40 mesh particles were taken for molding to obtain a blank.

[0030] (5) The blank is sintered, the pressure of the sin...

Embodiment 3

[0032] (1) Weigh and mix the main components, and the main components are calculated as Fe by mole percentage 2 o 3 52%, NiO19.5%, ZnO21.5%, CuO7%, take out and dry after ball milling for 1.5h.

[0033] (2) Carry out pre-firing in an air atmosphere, the pre-firing temperature is 900°C, and the holding time is 2h.

[0034] (3) According to the total mass of the main components, add subcomponents to the calcined material, the subcomponents are CoO0.10wt%, CaCO 3 0.10wt%, V 2 o 5 0.02wt%, Bi 2 o 3 0.10wt%, SnO 2 0.05 wt%.

[0035] (4) Secondary ball milling for 4 hours, after drying, add polyvinyl alcohol solution with a mass concentration of 10% as a binder, the addition amount is mainly 10% of the mass of the component, and zinc stearate is added as a release agent, the addition amount is mainly 0.2% of the mass of the ingredients, granulated, and the sieved -40 mesh particles were taken for molding to obtain a blank.

[0036] (5) The blank is sintered, the pressure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com