Equipment and method for removing proteins through membrane method

A protein and removal technology, applied in chemical instruments and methods, food industry wastewater treatment, special treatment targets, etc., can solve the problems of inability to continue to use cyclic pickling, low sanitation and safety, and death of surrounding water bodies. The effect of smooth pipeline layout, high degree of automation and efficient processing facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

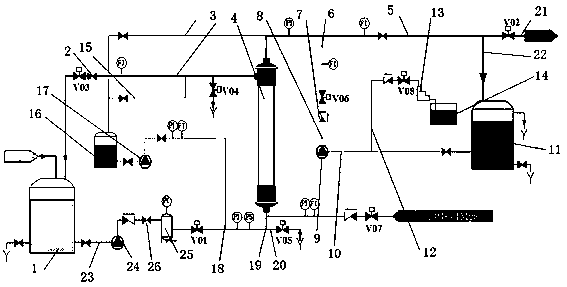

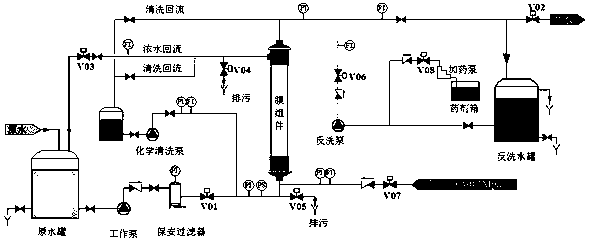

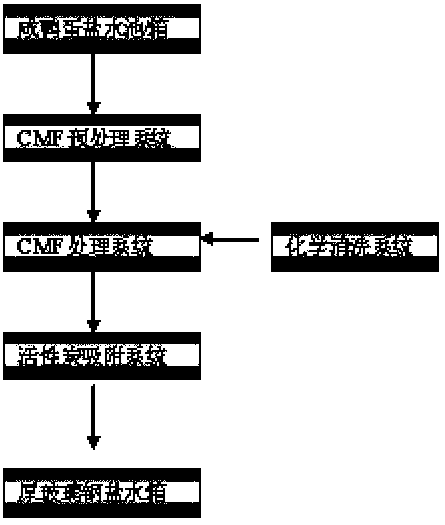

[0024] A kind of equipment that membrane method removes protein, and its composition comprises: raw water tank 1, described raw water tank connects control valve V03, described circulation valve V03 connects circulation valve 2, described circulation valve connects concentrated water return pipe 3 , the concentrated water return pipe is connected to the membrane module 4, the membrane module is connected to the circulation pipe 5, the circulation pipe is connected to the branch pipe 6, the branch pipe is connected to the control valve V06, and the control valve V06 is connected to One-way valve 7, the one-way valve is connected to the backwash branch pipe 8, the backwash branch pipe is connected to the backwash pump 9, the backwash pump is connected to the backwash pipe 10, and the backwash pipe is connected to the backwash pipe The water tank 11 , the backwash pipe is connected to the dosing pipe 12 , the dosing pipe is connected to the control valve V08 , the control valve V0...

Embodiment 2

[0027] The equipment for removing protein by membrane method described in Example 1, the membrane module is connected to the cleaning return branch pipe 15, the cleaning return branch pipe is connected to the chemical cleaning tank 16, and the chemical cleaning tank is connected to the chemical cleaning pump 17 , the chemical cleaning pump is connected to the blowdown pipe 18, the blowdown pipe is connected to the control valve V05, the membrane assembly is connected to the blowdown branch pipe 19, the blowdown branch pipe is connected to the blowdown pipe, and the blowdown branch pipe is connected to The discharge pipe 20, the discharge pipe is connected to the control valve V07.

Embodiment 3

[0029] In the equipment for removing protein by membrane method described in Example 1, the circulation pipe is connected to the control valve V02, and the control valve V02 is connected to the water production pipe 21; the circulation pipe is connected to the backwash branch pipe 22, and the The backwash branch pipe is connected to the backwash water tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com