A method and device for pickling copper oxide on the surface of drawn copper material

A technology for copper oxide and copper materials, applied in the field of metal oxide pickling, can solve the problems of pungency, pollution, yellow smoke, etc., and achieve the effect of reducing the cost of pickling and simple operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

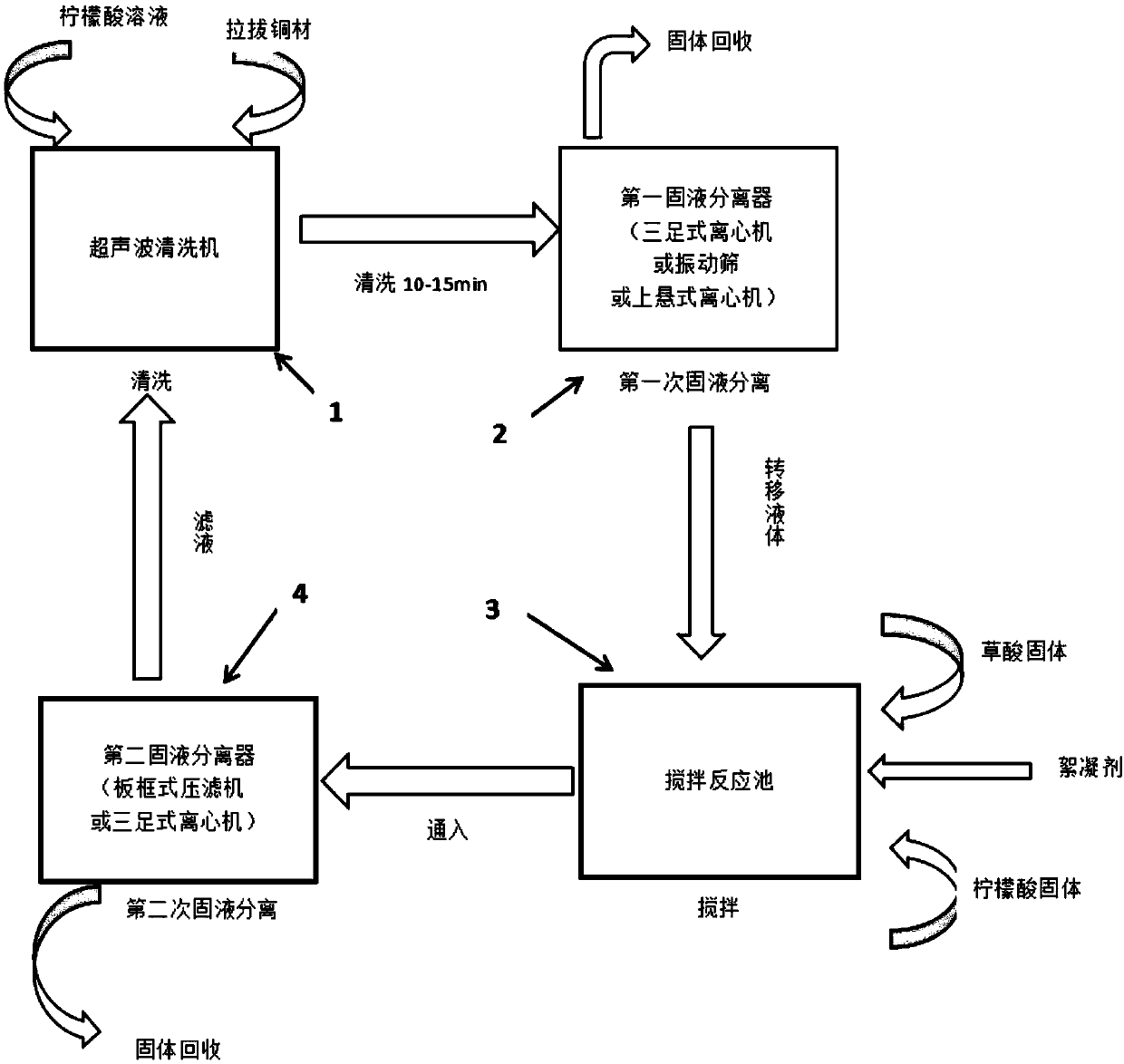

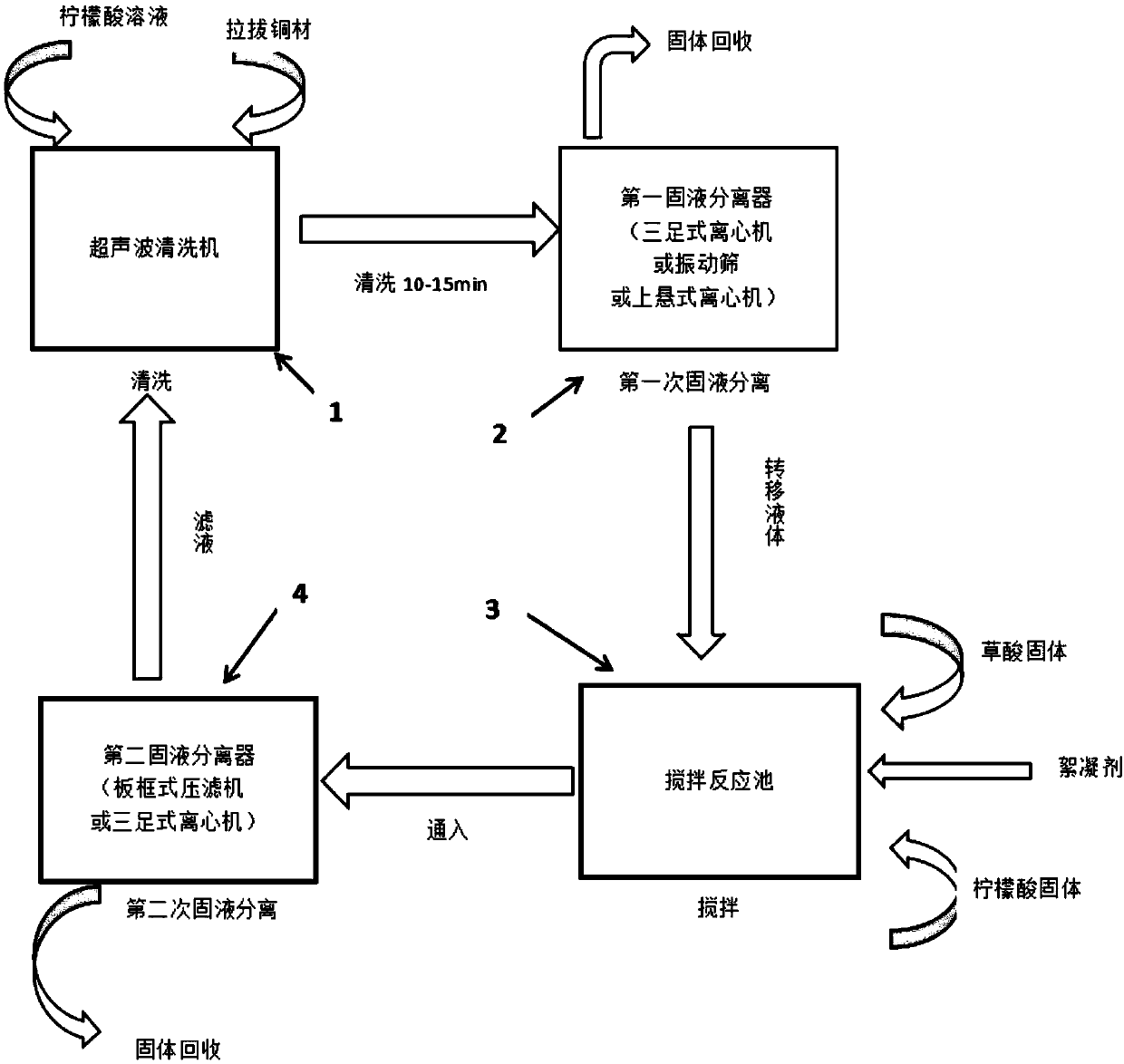

[0023] A method for pickling copper oxide on the surface of a drawn copper material, comprising the following steps:

[0024] S01: Put the drawn copper material into the ultrasonic cleaning tank 1 with citric acid solution for cleaning, the citric acid solution reacts with the copper oxide on the surface of the drawn copper material to form copper citrate; S02: Put the copper citrate in the ultrasonic cleaning tank in S01 The solid-liquid mixture is transferred to the three-legged centrifuge 2 for solid-liquid separation, and the solid is separated and reclaimed; S03: the liquid obtained in S02 is transferred to the stirring reaction tank 3, and then solid citric acid, The mixture of oxalic acid solid and flocculant, adding oxalic acid solid, can produce copper oxalate precipitation and citric acid solution, adding flocculant, can accelerate the rate of precipitation formation; S04: pass the mixture obtained by S03 into plate and frame filter press 4 Carry out solid-liquid sep...

Embodiment 2

[0027] A method for pickling copper oxide on the surface of a drawn copper material, comprising the following steps:

[0028] S01: Put the drawn copper material into the ultrasonic cleaning tank 1 with citric acid solution for cleaning, the citric acid solution reacts with the copper oxide on the surface of the drawn copper material to form copper citrate; S02: Put the copper citrate in the ultrasonic cleaning tank in S01 The solid-liquid mixture is transferred to the vibrating screen 2 for solid-liquid separation, and the solid is separated; S03: the liquid obtained in S02 is transferred to the stirring reaction tank 3, and then the mixture of citric acid solid, oxalic acid solid and flocculant is added, Adding solid oxalic acid can generate copper oxalate precipitation and citric acid solution, and adding a flocculant can accelerate the rate of precipitation formation; S04: pass the mixture obtained from S03 into the three-legged centrifuge 4 for centrifugation, and recover t...

Embodiment 3

[0032] A method for pickling copper oxide on the surface of a drawn copper material, comprising the following steps:

[0033] S01: Put the drawn copper material into the ultrasonic cleaning tank 1 with citric acid solution for cleaning, the citric acid solution reacts with the copper oxide on the surface of the drawn copper material to form copper citrate; S02: Put the copper citrate in the ultrasonic cleaning tank in S01 The solid-liquid mixture is transferred to the top suspension centrifuge 2 for solid-liquid separation, and the solids are separated; S03: transfer the liquid obtained in S02 to the stirring reaction tank 3, and then add citric acid solids, oxalic acid solids and flocculants The mixture, adding oxalic acid solid, can generate copper oxalate precipitation and citric acid solution, add flocculant, can accelerate the speed of precipitation generation; S04: pass the mixture that S03 obtains in the three-legged centrifuge 4 and carry out centrifugal operation, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com