High-temperature-resistant elevator brake

A technology for elevator brakes and high temperature resistance, applied in the direction of brake types, drum brakes, brake components, etc., can solve problems such as temperature rise, high temperature of friction brake pads, hidden safety hazards, etc., to reduce flame propagation speed and speed up exchange speed , strong corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

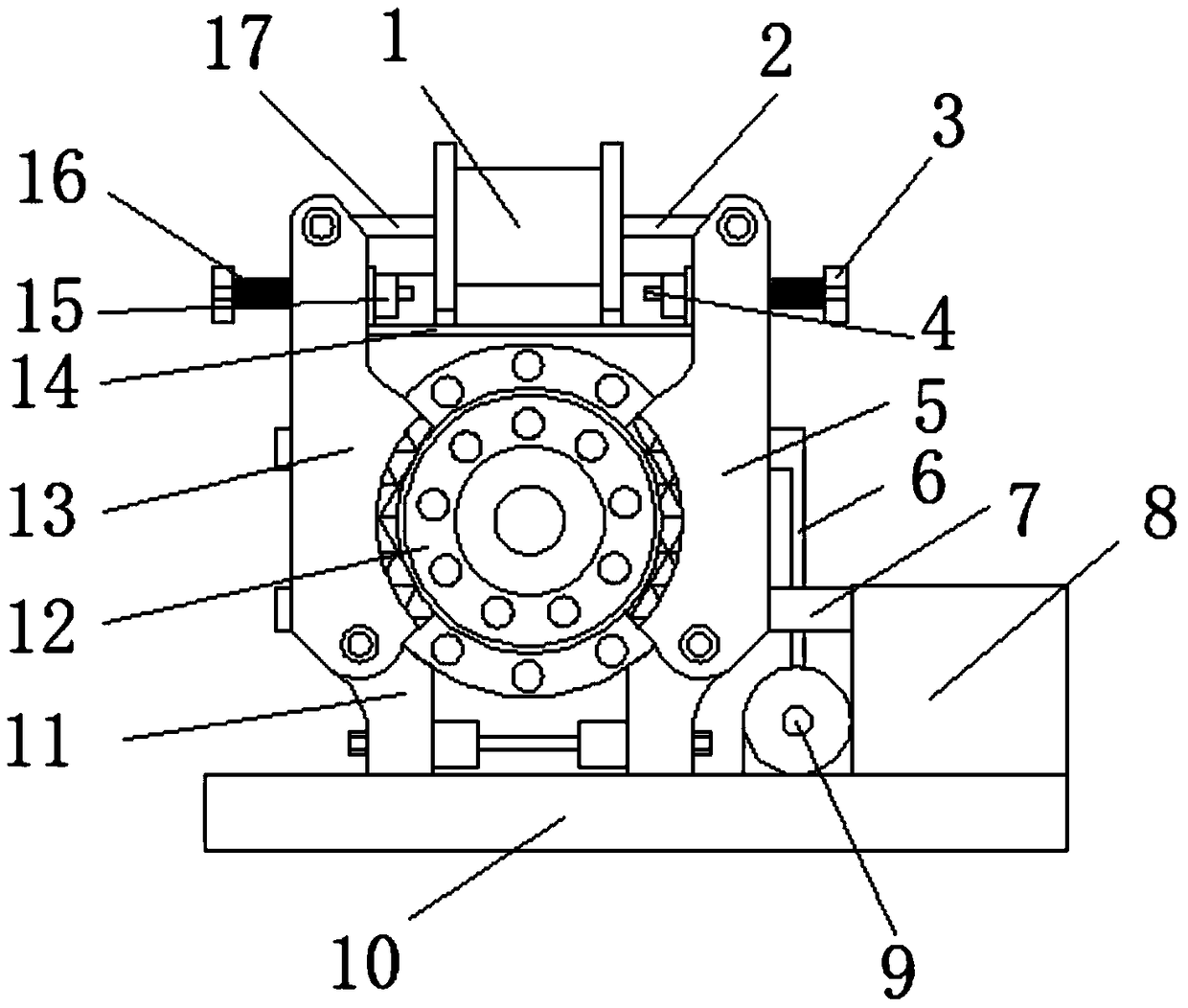

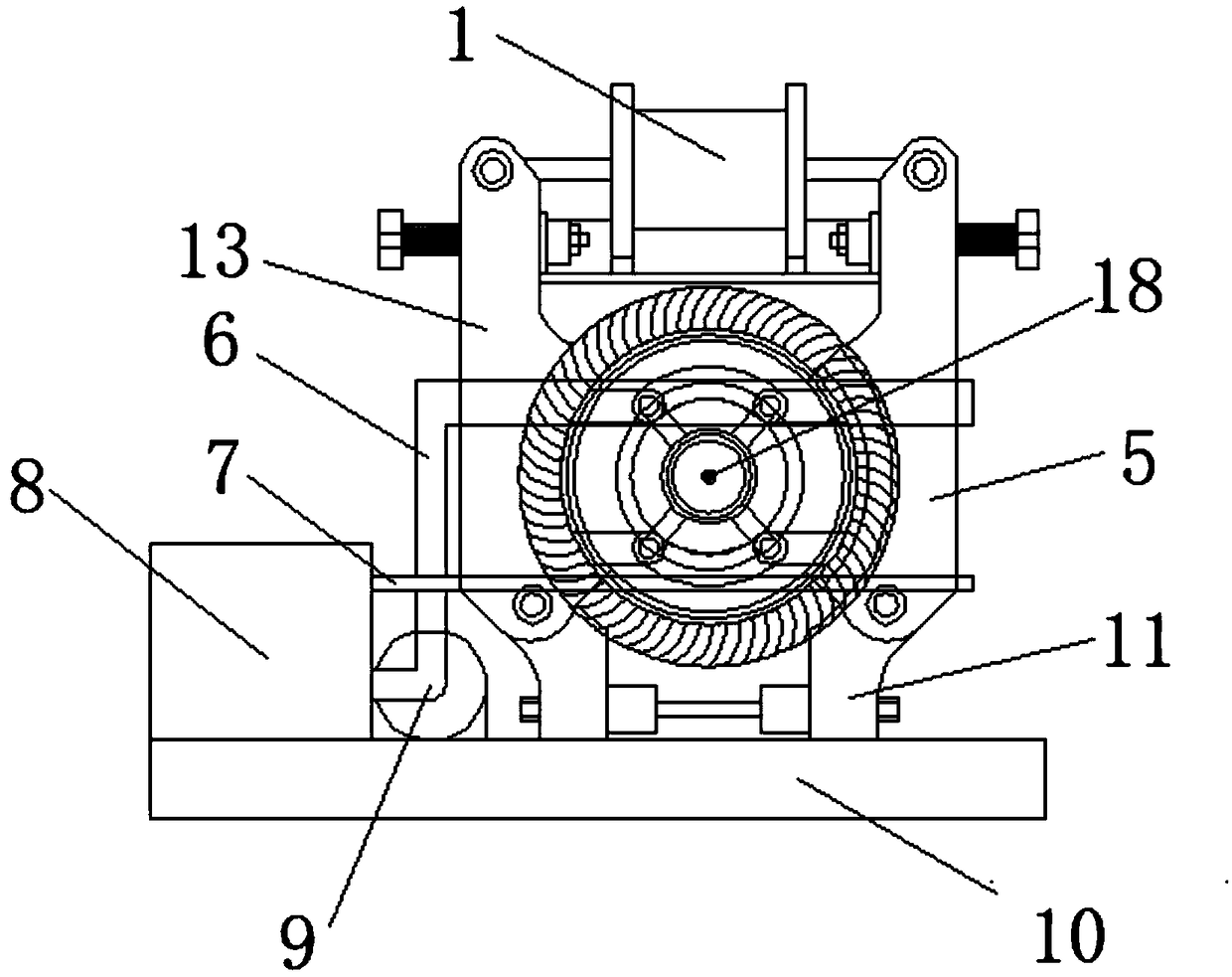

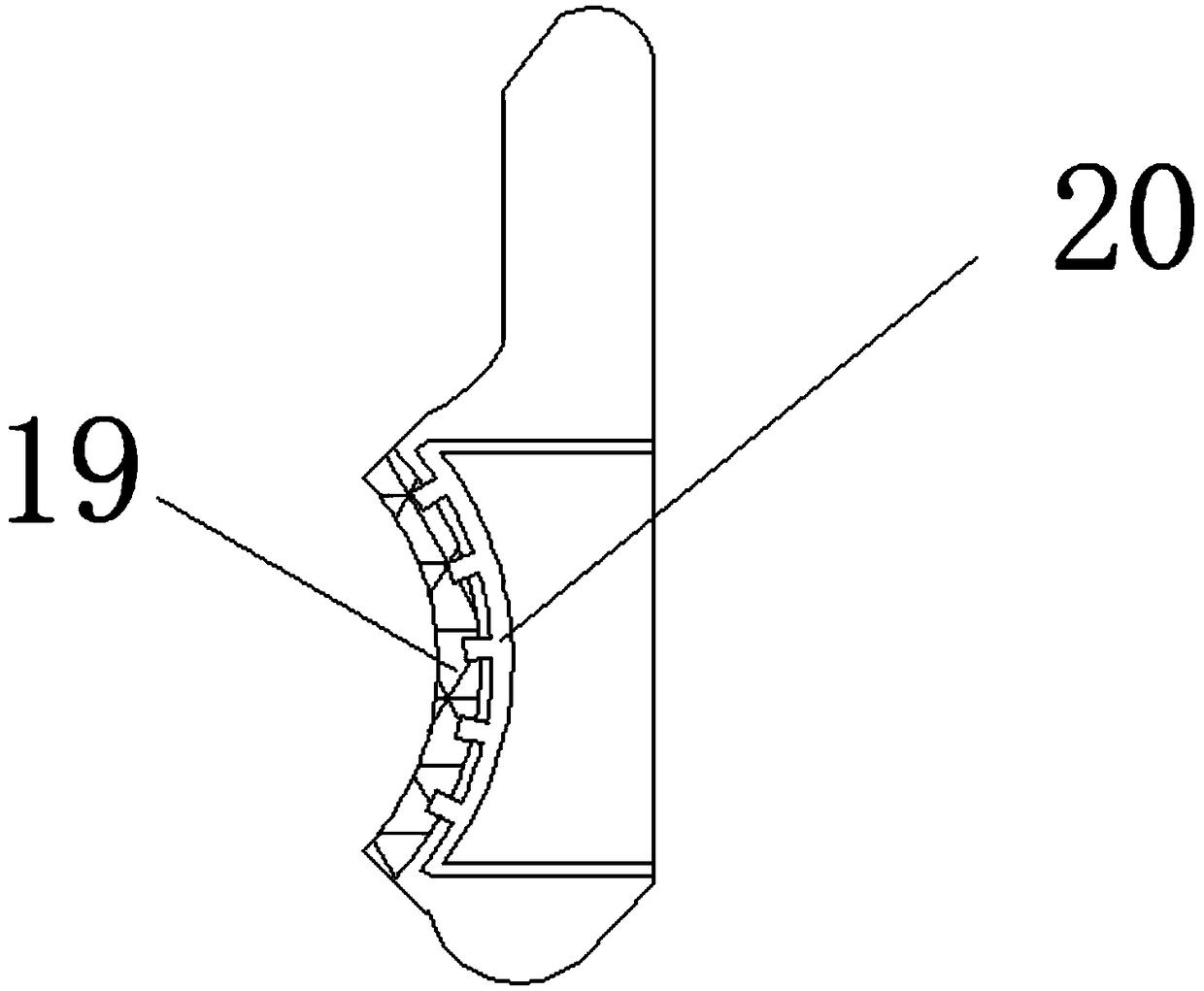

[0020] Such as Figure 1-4 As shown, a high temperature resistant elevator brake includes a two-way electromagnetic push rod 1, a body 11 and a base 10, the model of the two-way point magnetic push rod 1 is STZ (DZT), and the body 11 is fixedly connected to the base 10, The body 11 is welded with a back mounting plate 12, a fan 18 is installed on one side of the back mounting plate 12, and the model of the fan 18 is 280FLW2, and the two sides of the body 11 are connected with the left splint 13 and the right splint 5 respectively. Hinge connection, the left splint 13 and the right splint 13 are equipped with rubber plates 19, the left splint 13 and the right splint 13 are equipped with cooling pipes 20, the water inlet of the cooling pipe 20 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com