Conveyor belt cleaning device arrangement structure and cleaning method

A technology of cleaning device and arranging structure, applied in the direction of cleaning device, conveyor, conveyor objects, etc., can solve the problems of unclean conveyor belt material, conveyor belt deviation, return belt material, etc., to improve the ability and avoid running The effect of biasing and reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

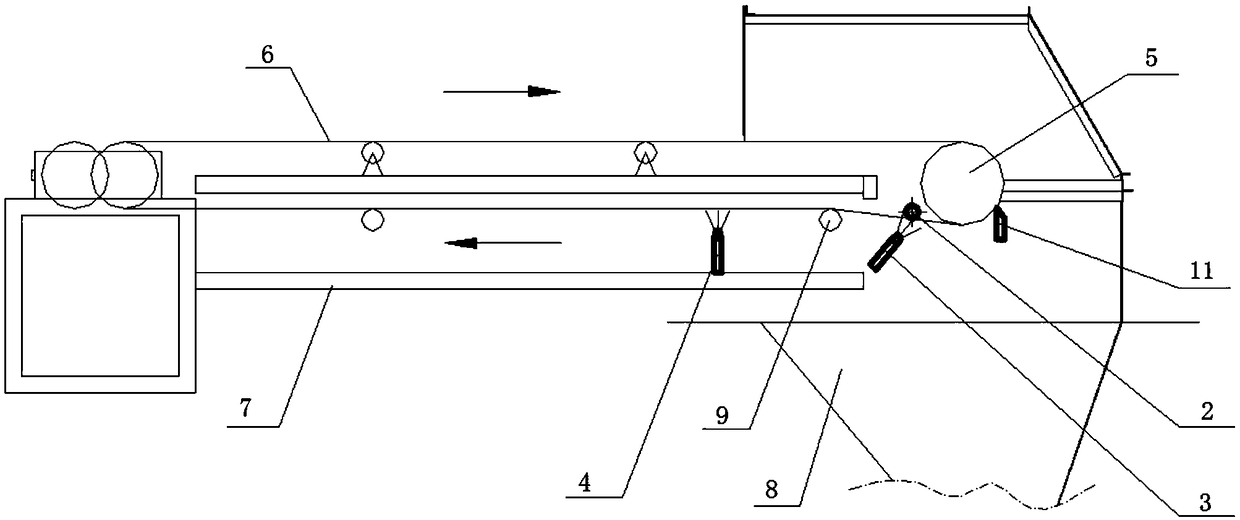

Embodiment 1

[0041] In this embodiment, the primary cleaning device includes a scraper 11, and the material humidifying device 4 is installed on the frame 7. Falling into the collecting hopper 8, the conveyor belt after blanking enters the return section, first scrapes off the large particle materials on the conveyor belt through the scraper 11, and then vibrates through the vibration mechanism 2 to destroy the gap between the small particle materials and the conveyor belt 6. Adhesive force, the small particle material is blown down into the collecting hopper 8 through the air blowing mechanism, and the conveyor belt after two cleanings is transported to the material humidification device 4, and the fine water particles are sprayed by the material humidification device 4 to increase the size of the material. Adhesion to the conveyor belt, avoiding falling during the return process, improving the scattering of materials and reducing pollution.

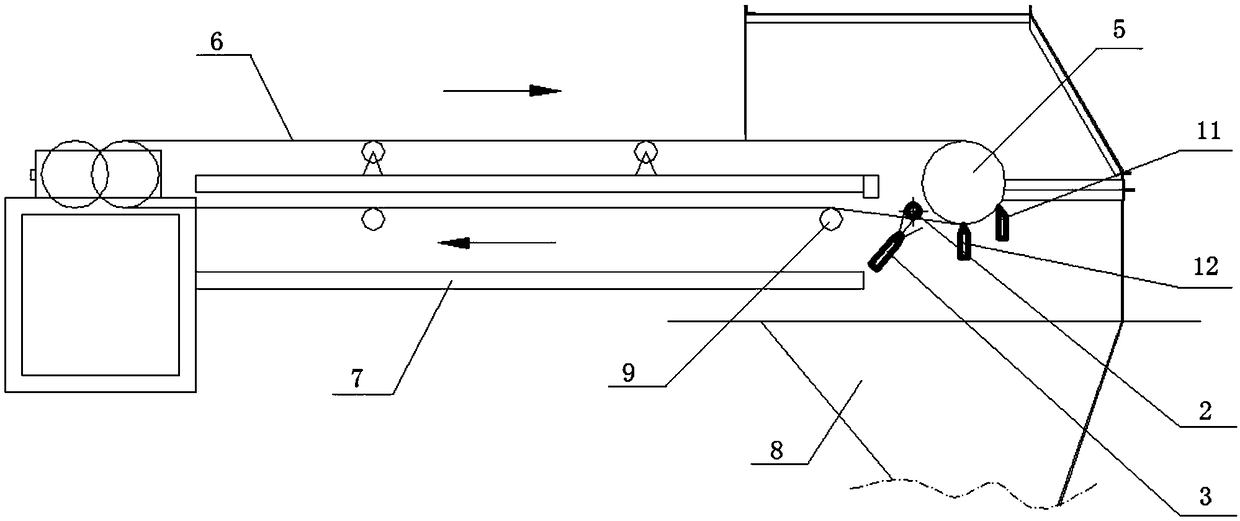

Embodiment 2

[0043] In this embodiment, when the moisture content of the material itself is relatively high, the material humidifying device can be cancelled, and the primary cleaning device includes two scrapers, and the scraper 11 and the scraper 12 are vertically arranged at the bottom of the roller 5 at the head of the conveyor. below, and successively use the scraper 11 and the scraper 12 to clean the large particle materials attached to the return section of the front end of the conveyor belt, and then vibrate through the vibration mechanism 2 to destroy the adhesion between the small particle materials and the conveyor belt 6. The air purging mechanism blows down the small particle materials into the collecting hopper 8, and through multiple cleanings, the materials with weak adhesion are separated from the conveyor belt and fall into the collecting hopper, reducing the return of the conveyor belt and the falling of the material on the way back , reduce environmental pollution, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com