template divider

A dividing machine and template technology, applied in plastic recycling, recycling technology and other directions, can solve the problems of different sizes of template fragments and increased melting time of template fragments, so as to achieve basically the same melting speed, increase melting time, and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

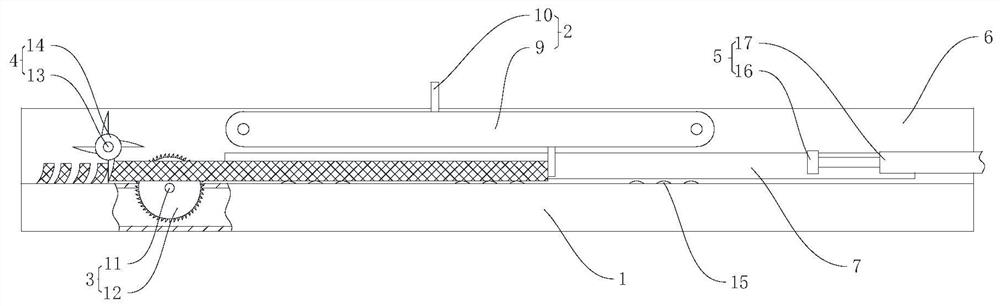

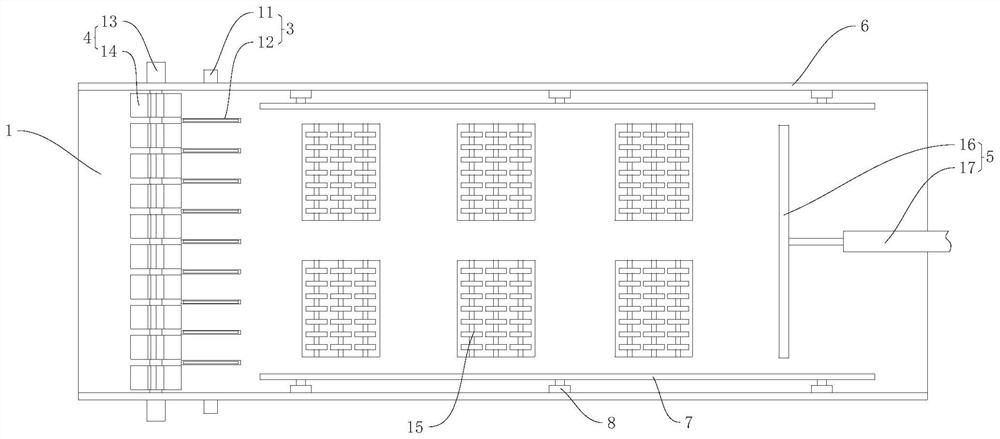

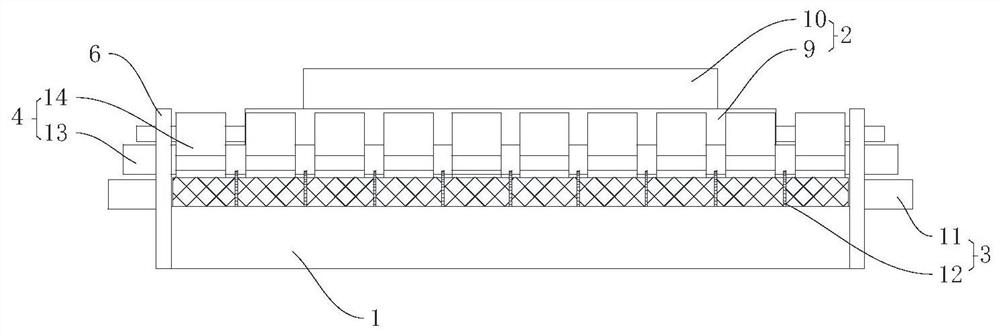

[0029] Furthermore, please also refer to figure 1 and figure 2 , as a specific embodiment of the template dividing machine provided by the present invention, the push plate assembly 5 includes a push plate 16 for pushing the template to the bottom of the drive assembly 2 and a cylinder 17 that drives the push plate 16 to move, and the cylinder 17 is arranged horizontally. The right end of the cylinder 17 is the cylinder body, and the left end is the ejector rod. The cylinder body is fixed on the right end of the workbench 1, and the cylinder body can also be fixed separately. It is necessary to ensure that the cylinder 17 is stable, and the left end of the ejector rod is welded and fixed vertically to the push plate 16. Can be one, also can be a plurality of air cylinders 17 of synchronous operation, when a plurality of air cylinders 17 are set, must guarantee the synchronous operation of air cylinder 17, air cylinder 17 also can be hydraulic cylinder, electric push rod etc.,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com