End cover cutting device for waste laundry detergent bottles

A cutting device and laundry detergent technology, applied in metal processing, etc., can solve problems such as low efficiency, time-consuming and labor-consuming, unfavorable recycling operations, etc., and achieve the effects of improving production efficiency, high operating efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

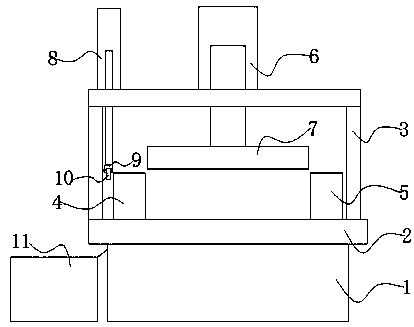

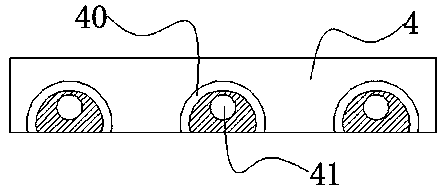

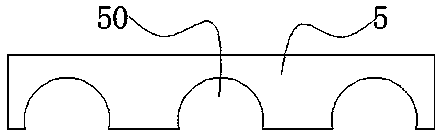

[0015] Such as Figure 1-4 As shown, the invention discloses an end cap cutting device for waste laundry liquid bottles, including a base 1 and a cutting table 2, the base 1 is fixedly installed with a cutting table 2, and the cutting table 2 is provided with four A vertical pole and a top plate fixedly installed on its top are combined to form an equipment installation bracket 3, and the left and right sides of the cutting table 2 are fixedly installed with a left clamping block 4 and a right clamping block 5 respectively. The clamping block 4 is provided with a plurality of left side bottle body step holes 40, and an end cap avoidance hole 41 is opened and penetrated on each of the left side bottle body step holes 40, and the right side clamping block 5 There are a plurality of through holes 50 on the right side of the bottle body, and an oil cylinder 6 is fixedly installed at the center of the top plate of the equipment installation bracket 3, and the bottom end of the tele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com