Edge grinding machine for two straight edges of glass

An edger and bilateral technology, applied in machine tools, grinding frames, and grinders suitable for grinding the edge of workpieces, can solve the problems of glass processing, scratches on the surface, inconvenience to view data, etc. The effect of reducing the probability of occupational diseases, preventing unqualified glass quality, and facilitating the viewing of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

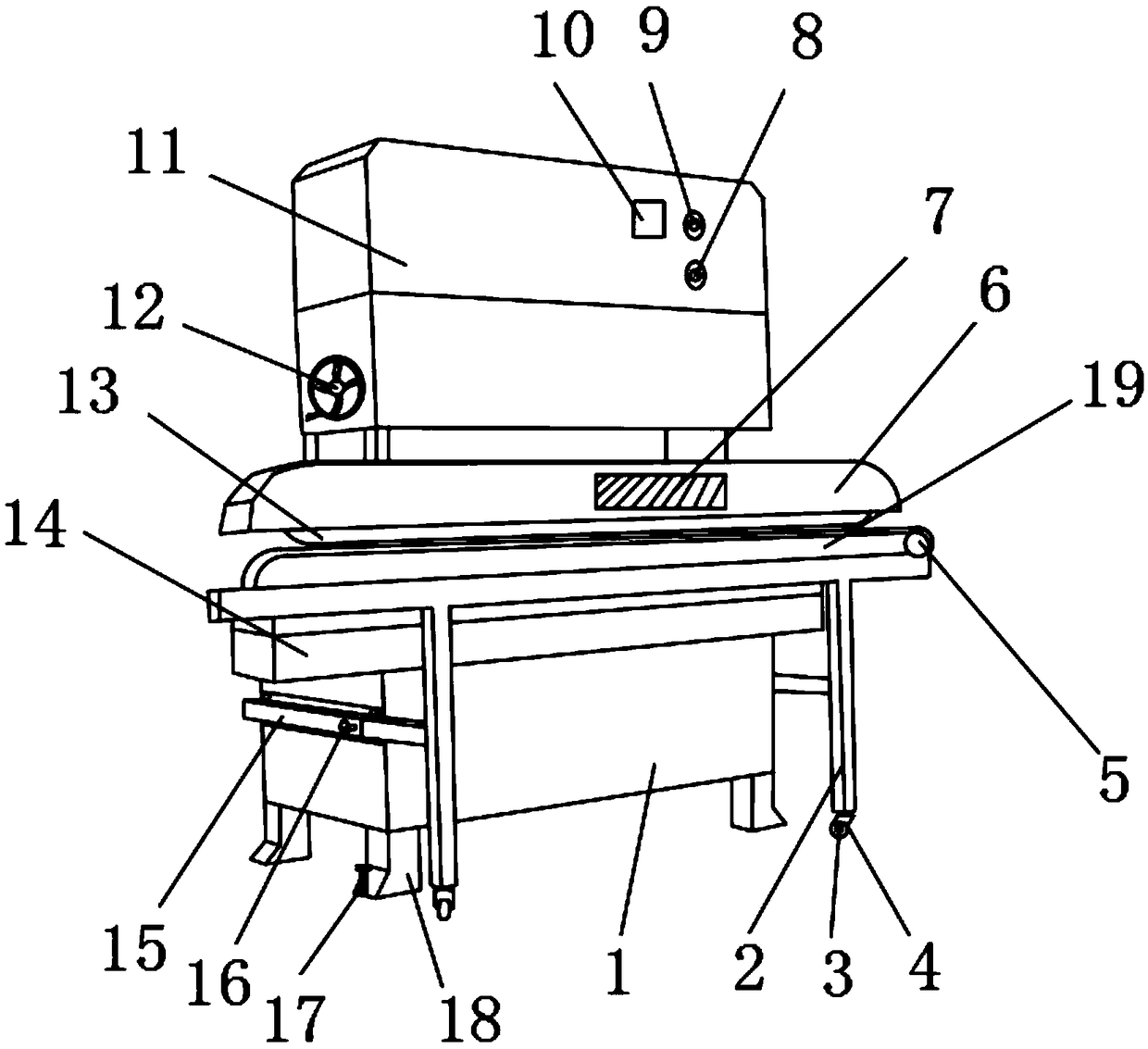

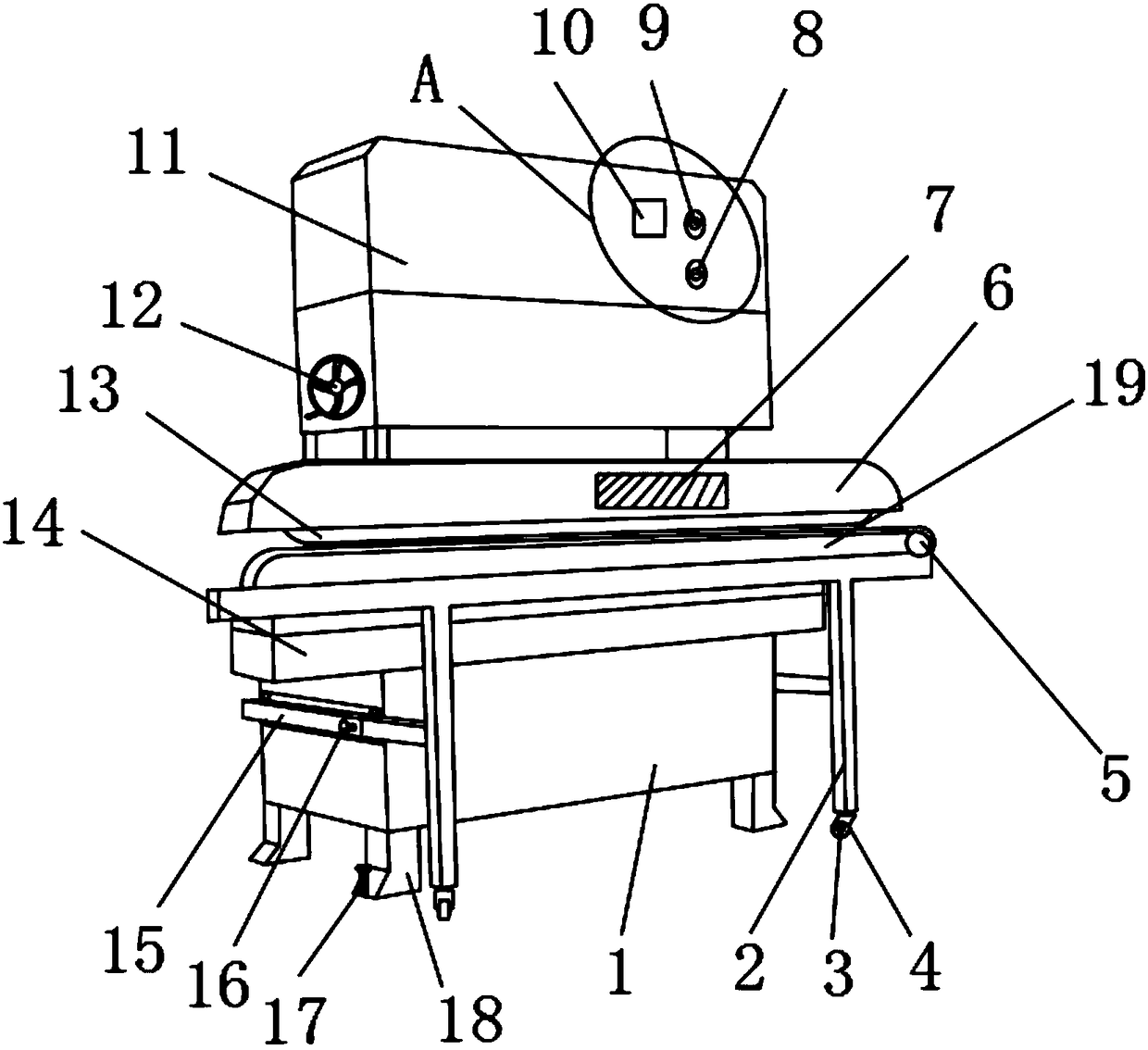

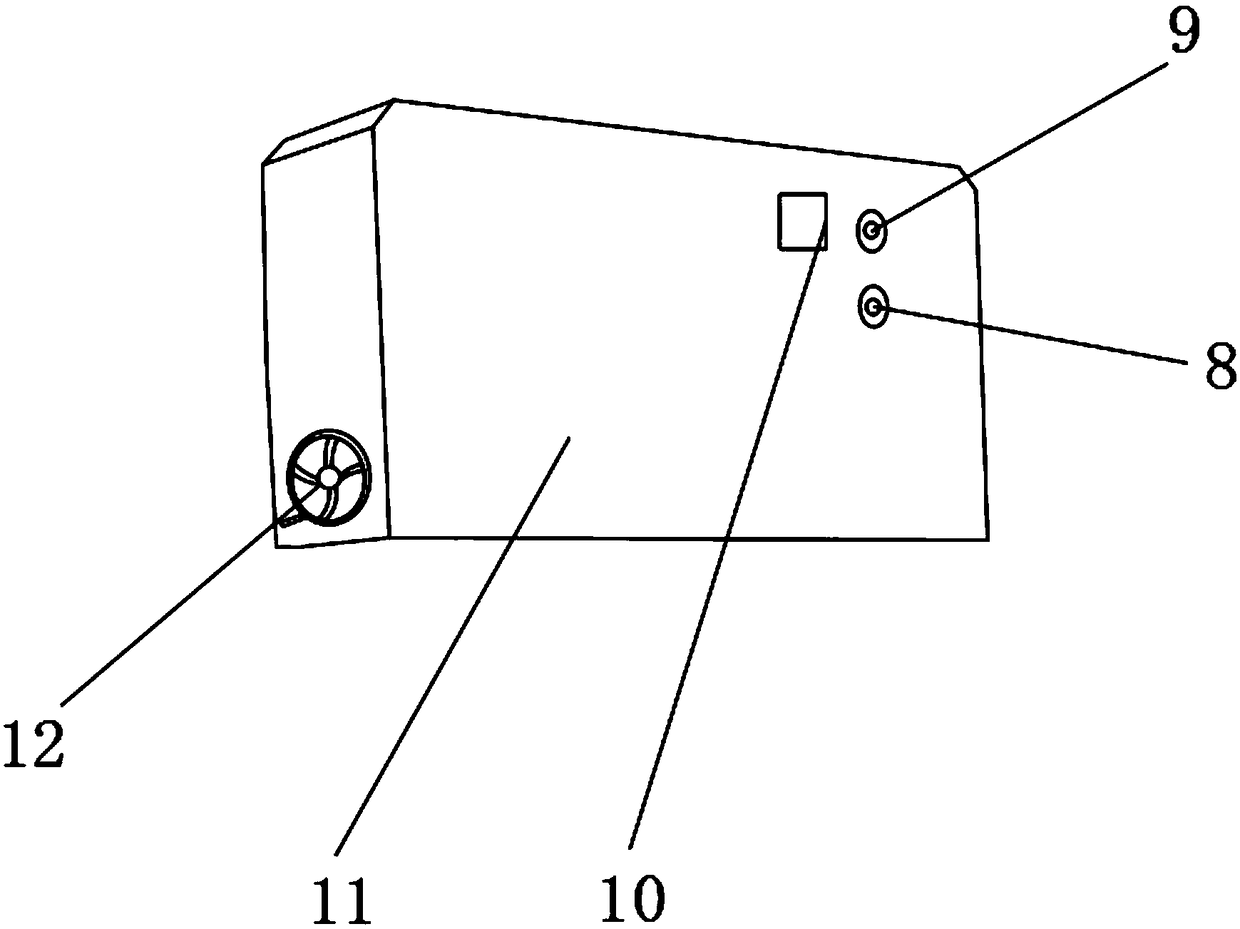

[0018] Such as Figure 1-4 As shown, a kind of edging machine that is used for glass bilateral straight edge comprises frame 1, support 2 and upper grinding head 13, and the upper end of described frame 1 is fixedly installed with workbench 14, and the lower end of frame 1 is fixed Organic pin 18 is installed, and the two ends of described frame 1 are all provided with guide rail 15, and one end of described machine pin 18 is provided with balance adjustment screw 17, and the lower end of described support 2 is provided with pulley 4, and one end of support 2 is provided with There are tightening bolts 16, the bracket 2 is flexibly connected with the guide rail 15 through the tightening bolts 16, one end of the pulley 4 is provided with a connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com