Plate cutting machine

A cutting machine and plate technology, applied in the field of plate processing, can solve the problems of time-consuming and laborious replacement of cutters, low cutting efficiency, time-consuming and labor-intensive, etc., and achieve the advantages of reducing lumbar muscle strain, simple structure, and reducing tool changing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

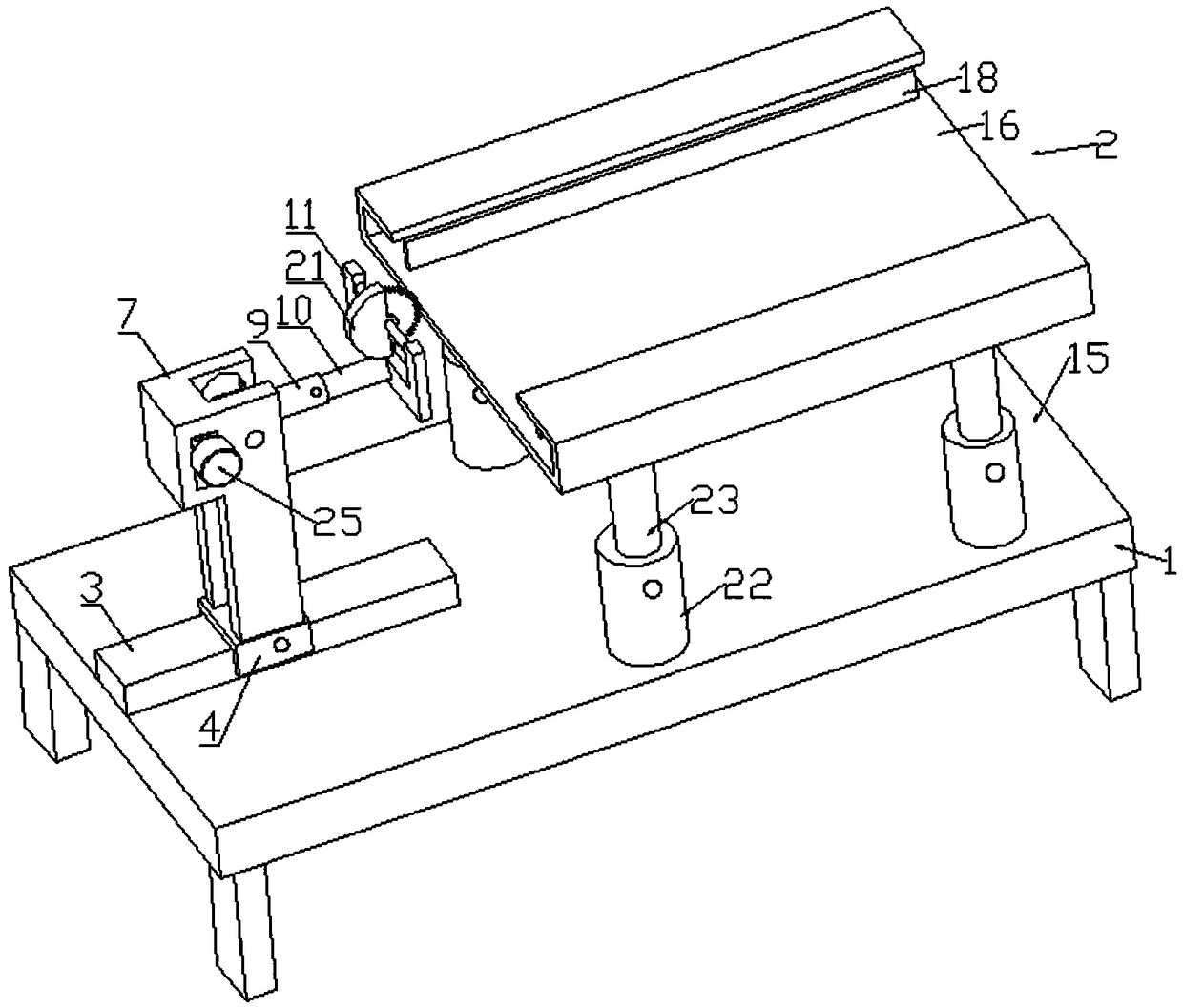

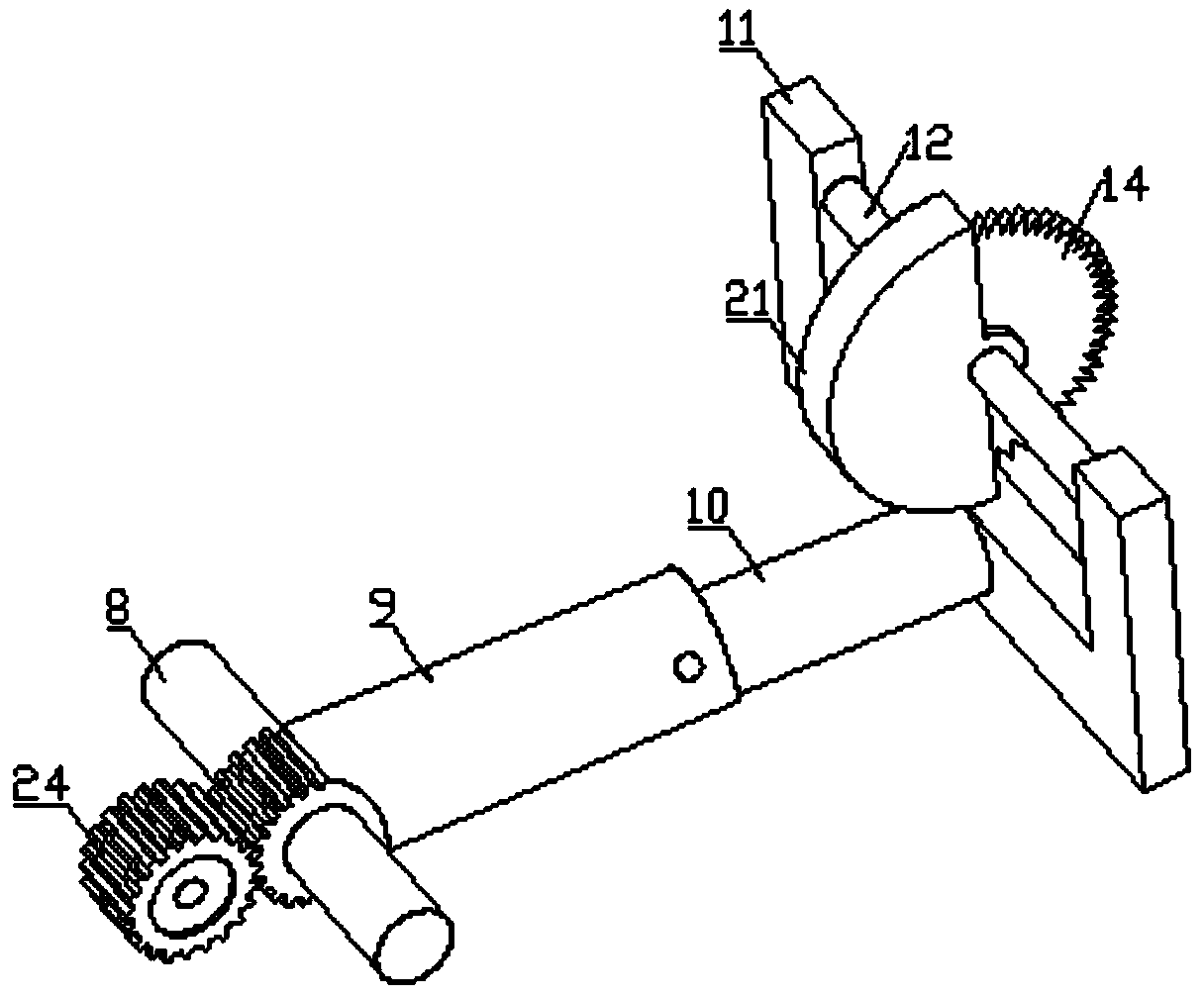

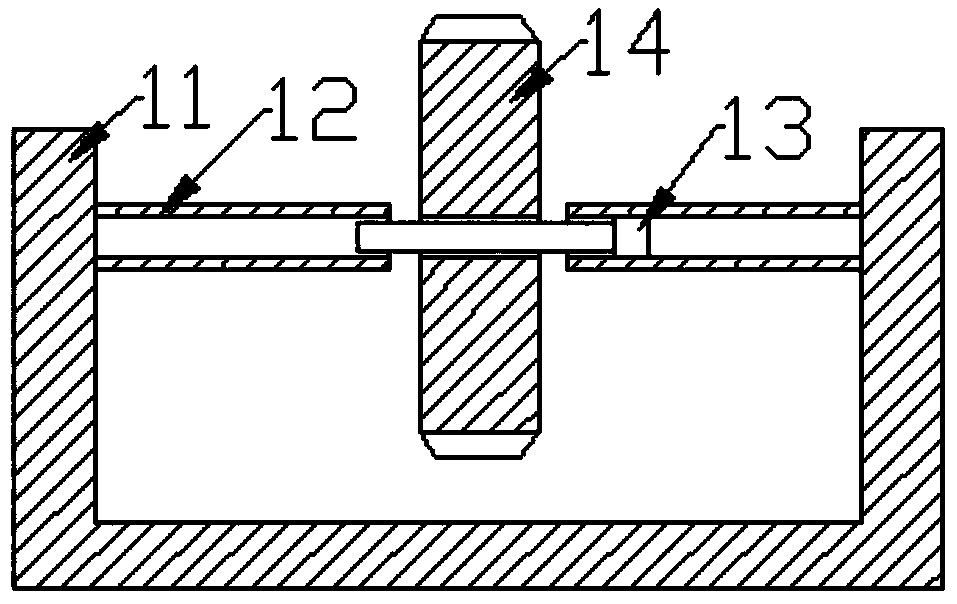

[0021] Such as Figure 1 to Figure 6 As shown, a plate cutting machine includes a worktable 1, on which a support 2 and a guide rail 3 are fixedly installed, the guide rail 3 is slidably connected to a sliding plate 4, and the sliding plate 4 is provided with screw holes and The guide rail 3 is connected by tightening screws. The guide rail 3 is provided with a driving mechanism 5, the sliding plate 4 is provided with a rack 6, and the driving mechanism 5 drives the rack 6 and the sliding plate 4 to move linearly along the guide rail 3. The sliding plate 4 is fixedly connected to a bracket 7, and the two brackets 7 are rotated to connect a cross bar 8. The middle part of the cross bar 8 is sleeved with a special-shaped sleeve 9, and the end of the special-shaped sleeve 9 is sleeved with a sleeve rod 10 and connected by fastening screws , The sleeve rod 10 is fixedly connected to the cutter holder 11, and the cutter holder 11 is fixed with a connecting shaft 12, the shaft 12 is ...

Embodiment 2

[0024] Such as Figure 1 to Figure 6 As shown, a plate cutting machine includes a worktable 1, on which a support 2 and a guide rail 3 are fixedly installed, the guide rail 3 is slidably connected to a sliding plate 4, and the sliding plate 4 is provided with screw holes and The guide rail 3 is connected by tightening screws. The guide rail 3 is provided with a driving mechanism 5, the sliding plate 4 is provided with a rack 6, and the driving mechanism 5 drives the rack 6 and the sliding plate 4 to move linearly along the guide rail 3. The sliding plate 4 is fixedly connected to a bracket 7, and the two brackets 7 are rotated to connect a cross bar 8. The middle part of the cross bar 8 is sleeved with a special-shaped sleeve 9, and the end of the special-shaped sleeve 9 is sleeved with a sleeve rod 10 and connected by fastening screws , The sleeve rod 10 is fixedly connected to the cutter holder 11, and the cutter holder 11 is fixed with a connecting shaft 12, the shaft 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com