Rolling oil system of four-roller cold rolling mill

A rolling oil and cold rolling mill technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of inability to guarantee the cleanliness of the four-roll cold rolling mill, poor rolling stability, waste of resources and the environment, etc. Achieve surface cleanliness, ensure rolling stability, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

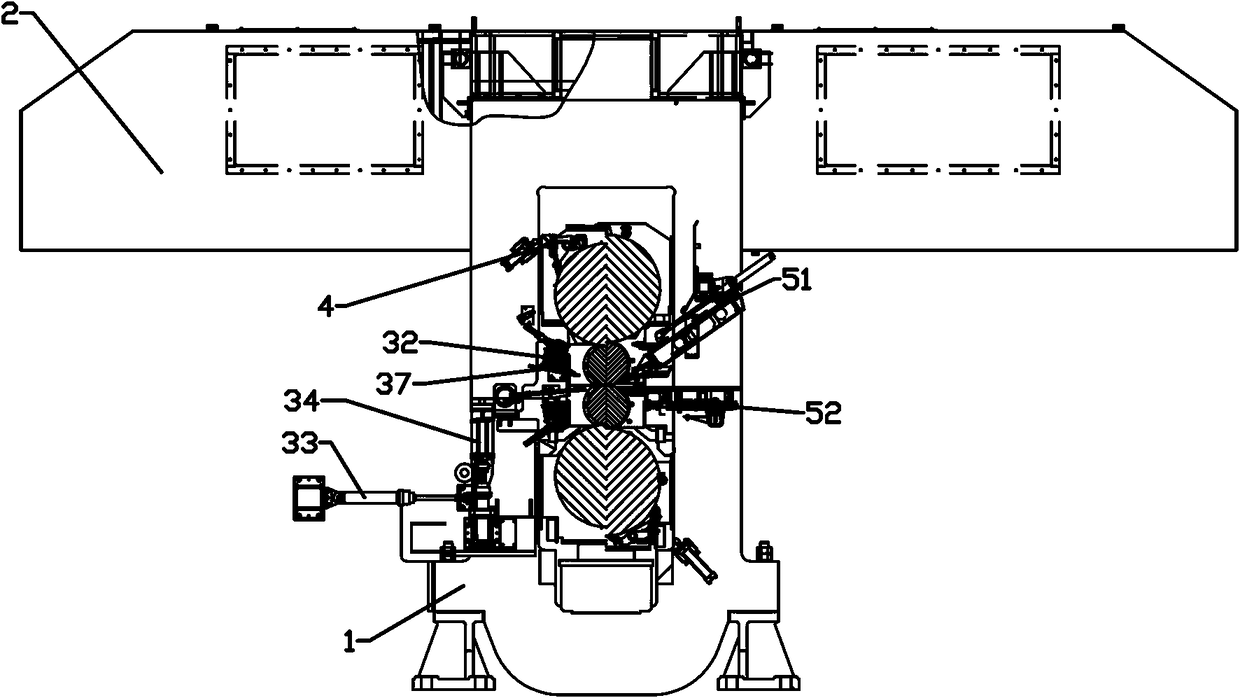

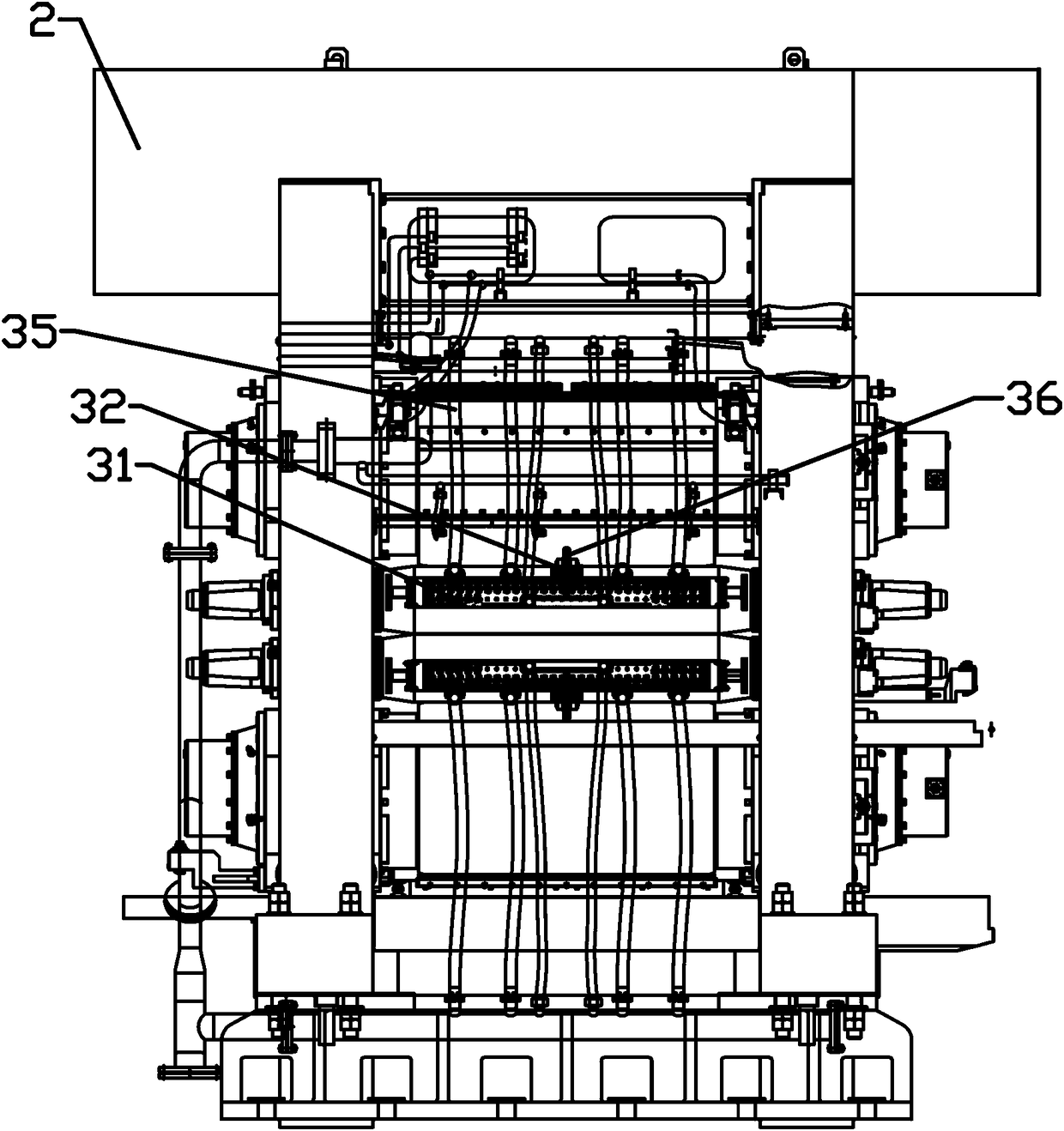

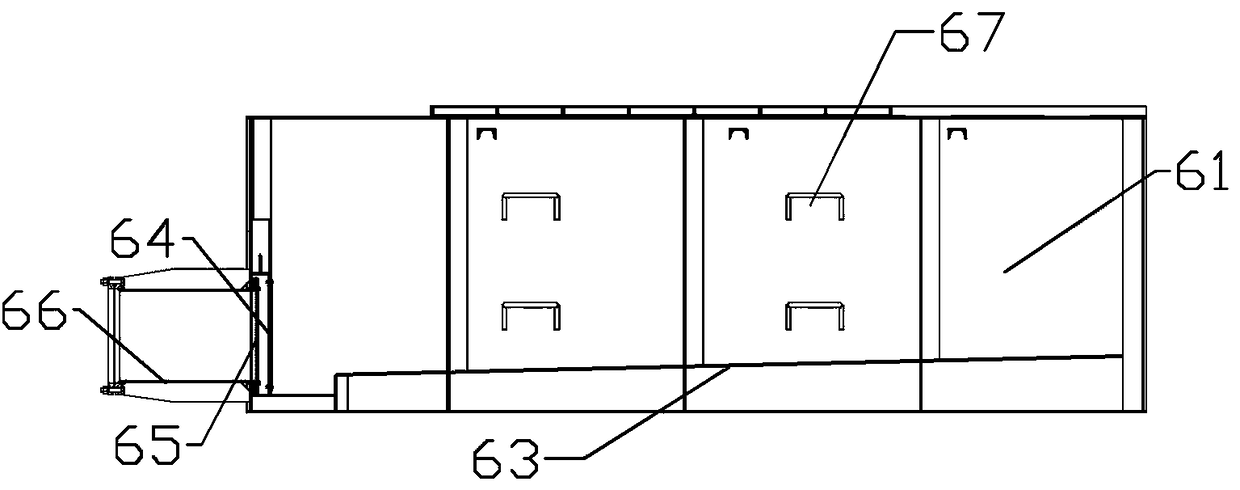

[0033] Such as Figure 1-10 As shown, a rolling oil system of a four-high cold rolling mill includes a frame 1 and a rolling oil system. The rolling oil system includes a nozzle beam device installed outside the feed inlet of frame 1, and the nozzle beam The device includes a nozzle beam slide seat 34, the nozzle beam slide seat is connected with a nozzle beam slide seat oil cylinder 33, a nozzle beam 31 is installed on the nozzle beam slide seat, the nozzle beam is divided into an upper nozzle beam and a lower nozzle beam, and the lower end of the upper nozzle beam and the lower nozzle beam Feeding guide plates 37 are installed on the upper ends of the nozzle beams, and the upper nozzle beams and the lower nozzle beams are connected with oil pipes 35 through their respective control valves 32. In this embodiment, the control valves 32 are dual-channel pneumatic valves, and any channel includes PAR Three gas ports are convenient for control, and the R ports of the two channels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com