A Method for Continuously Rolling Small Size Bars with 200 Large Section Billets

A technology of large section and small size, which is applied in the field of continuous rolling of small size bars with 200 large section billets, can solve the problems of high consumption, difficult maintenance and replacement, high downtime rate, and improve production efficiency and efficiency. , The effect of improving metal yield and reducing heating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

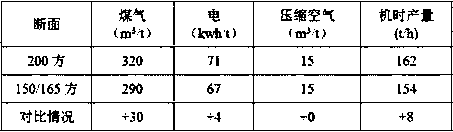

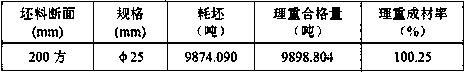

[0033] Taking 200×200×12000mm large section billet rolling Ф25mm bar as an example, the specific steps are as follows:

[0034]1. The 200mm×200mm×12000mm large-section billet is heated to 1100°C by the end-in and side-out push steel heating furnace with a cold billet heating capacity of 180t / h and soaked for heat preservation;

[0035] 1.1. Furnace bottom strength check

[0036] Calculation formula from furnace bottom strength: P=G / S (where: P: furnace bottom strength [kg / (m 2 .h)]; G: furnace output, kg / h; S: furnace effective area m 2 ), when rolling 200 square meters, the strength of the furnace bottom meets rolling 200mm×200mm×12000mm.

[0037] 1.2. Water beam strength check

[0038] Wyq<Wsj (where: Wsj is the section coefficient of the water beam), the strength is checked to meet the process requirements,

[0039] The deflection fmax<0.002 meets the requirements.

[0040] 1.3, heating time check

[0041] Calculate the heating time of rolling 230 square billets accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com