Sawdust tailings cleaning device for production of new energy

A cleaning device and new energy technology, which is applied in the direction of solid separation, etc., can solve the problems of difficult removal of dirt, waste of sawdust resources, impact of dirt, etc., and achieve the effects of avoiding tighter bonding, improving filtering effect, and improving utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

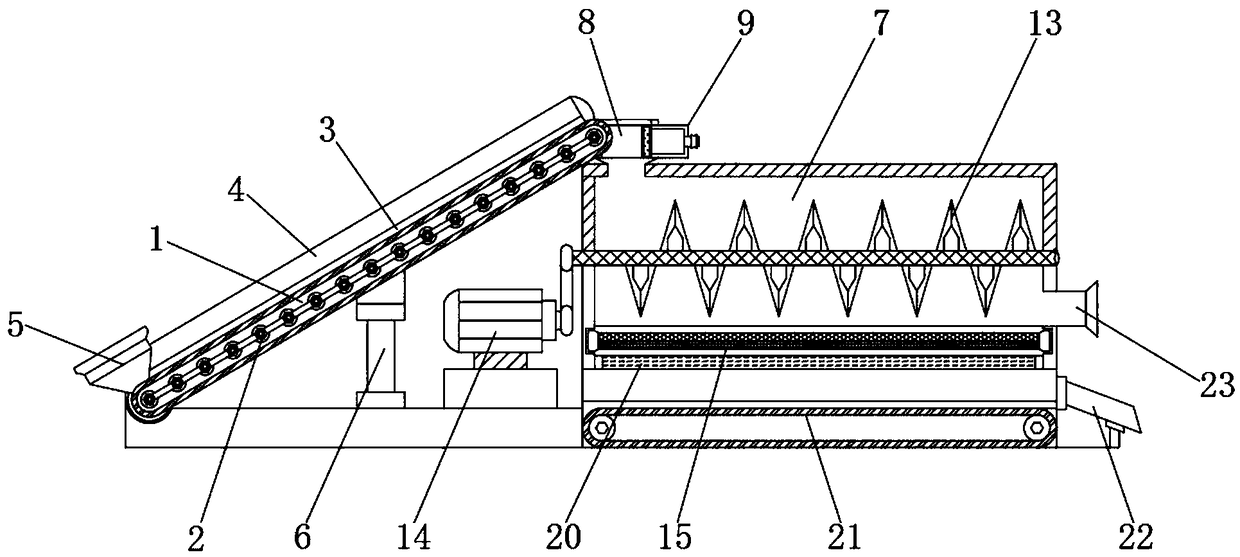

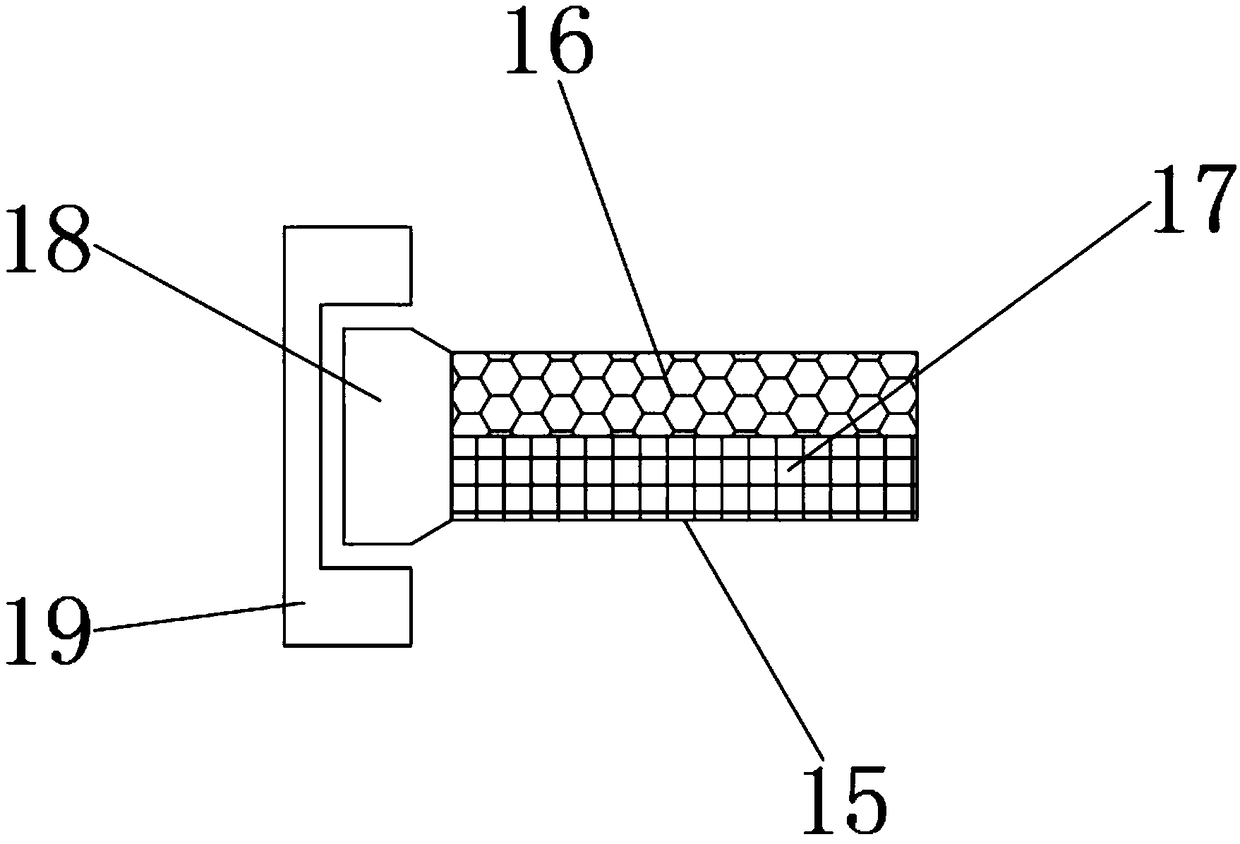

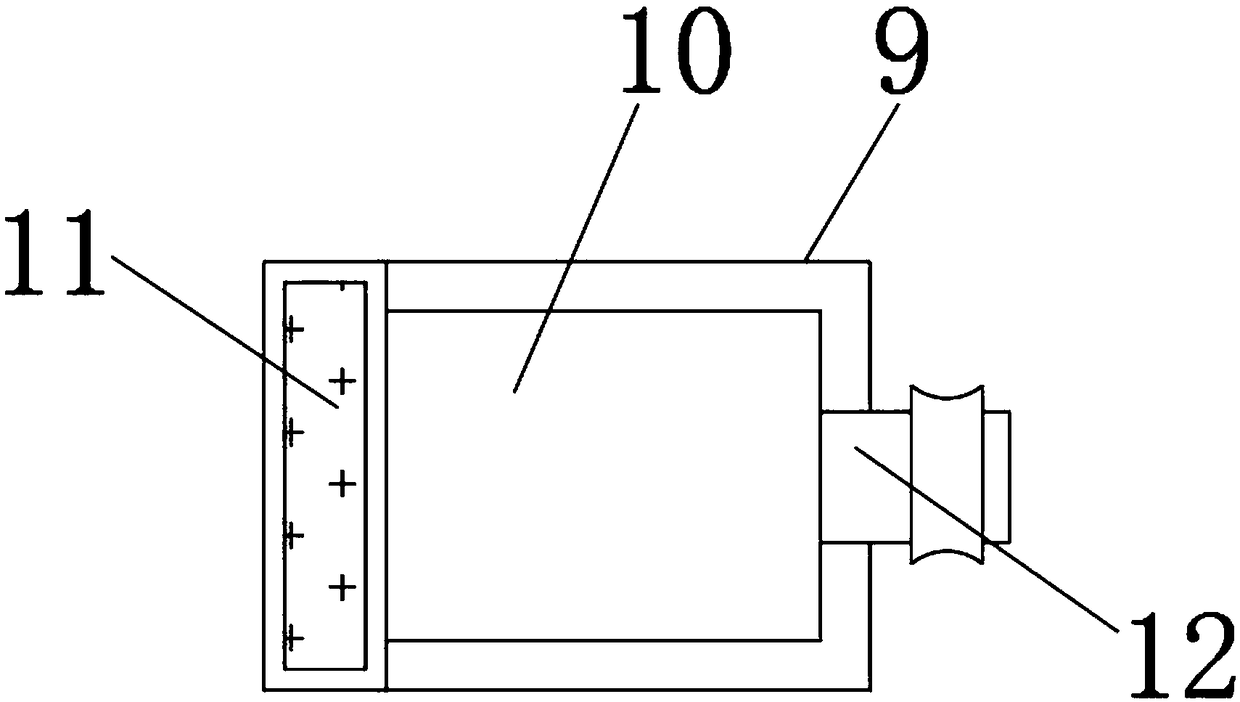

[0023] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a device for cleaning wood chips and tailings for new energy production, including a lifting conveyor belt 1, a synchronous roller 2, an overflow baffle 3, a protective cover 4, and a first feeding port 5 , hydraulic telescopic rod 6, screening chamber 7, second feed port 8, iron removal box 9, iron filings collection chamber 10, strong iron-absorbing magnetic block 11, sewage outlet 12, turning auger 13, power motor 14, Screening assembly 15, primary filter screen 16, secondary filter screen 17, mounting end plate 18, coupling groove 19, motorized vibrating plate 20, conveyor belt 21, waste outlet 22 and debris outlet 23, lift conveyor belt 1 The inner middle end is rotated and installed with synchronous rollers 2, and the outer edge of the lifting conveyor belt 1 is fixed and installed with an anti-overflow baffle 3 by welding, and a protective cover 4 is fixed on the outer sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com